Japanese standard JISH5302 2000 aluminum alloy die castings

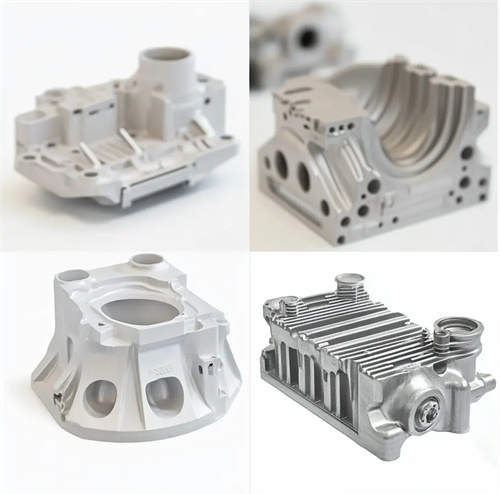

Japanese standard JISH5302-2000 holds distinct characteristics and significant guiding significance in the field of aluminum alloy die-casting. It provides solid technical support for domestic aluminum alloy die-casting production and has considerable international influence. This standard comprehensively covers a range of requirements for aluminum alloy die-casting, from raw material selection and production process control to final product quality testing. It aims to ensure high-quality, high-performance aluminum alloy die-castings to meet the diverse needs of various industries.

In terms of the chemical composition specifications for aluminum alloys, JISH5302 2000 has made detailed and scientific definitions of the content of various alloying elements. For common alloying elements such as silicon, magnesium, copper, etc., the standard sets precise content ranges based on different aluminum alloy grades. Silicon in aluminum alloys can significantly improve its casting properties, allowing the molten metal to better fill the complex cavity of the mold during the die-casting process, thereby producing die-castings with high dimensional accuracy and good surface quality. The addition of magnesium helps to improve the corrosion resistance and mechanical properties of aluminum alloys, especially in some application scenarios with high requirements for corrosion resistance, such as aluminum alloy die-castings in marine equipment, outdoor facilities and other fields. Reasonable control of magnesium is crucial. At the same time, the standard strictly limits the content of harmful impurity elements to prevent them from adversely affecting the performance of aluminum alloys and ensuring the stability of product quality.

Mechanical performance requirements are a key aspect of JIS H 5302 2000. This standard specifies mechanical performance indicators, such as tensile strength, yield strength, elongation, and hardness, for aluminum alloy die-castings for different applications. In the automotive industry, aluminum alloy die-castings are widely used in key components such as engine blocks and wheel hubs. These components must withstand heavy loads and complex stress environments, necessitating extremely stringent mechanical performance requirements. The mechanical performance indicators specified in JIS H 5302 2000 ensure that automotive aluminum alloy die-castings maintain excellent performance over long-term use, guaranteeing safe vehicle operation. In certain electronic equipment applications, where lightweighting and flexibility are paramount, the standard also establishes appropriate requirements for elongation and other indicators of aluminum alloy die-castings to meet product design and operational needs.

To ensure that the quality of aluminum alloy die-castings meets standard requirements, JIS H5302 2000 provides detailed specifications for testing methods. For chemical composition testing, advanced and accurate analytical methods such as spectral analysis and chemical titration are recommended. Specific instructions are provided for sample collection, processing, and instrument operation during the testing process to ensure the accuracy and reliability of test results. For mechanical property testing, strict regulations are in place for test equipment, specimen preparation, test procedures, and result evaluation for tensile, impact, and hardness tests. These standardized testing methods enable different manufacturers and testing organizations to obtain consistent and comparable test results, providing strong support for the quality assessment and market distribution of aluminum alloy die-castings.

In terms of quality control and management, JISH5302-2000 establishes comprehensive inspection rules. It clearly defines the items, frequency, and criteria for factory inspection and type inspection of aluminum alloy die-castings. Factory inspection is a routine quality control measure for each batch of products, focusing on spot checks of product appearance, dimensional accuracy, chemical composition, and key mechanical properties to promptly identify and eliminate substandard products. Type inspection is a comprehensive inspection conducted in critical circumstances such as product design changes, production process adjustments, and raw material replacements. It covers all technical requirements specified in the standard to ensure stable and consistent product quality. This rigorous inspection system encourages companies to continuously optimize production processes, strengthen quality control, and improve the overall quality of aluminum alloy die-castings, thereby promoting the sustainable and healthy development of Japan’s aluminum alloy die-casting industry.