German standard DIN743-78 purity cast zinc alloy

As a key standard for pure cast zinc alloys, the German standard DIN 743-78 holds a crucial position within the German industrial system. Germany is renowned for its rigorous industrial standards and high-quality products, and the development of DIN 743-78 embodies this rigorous approach. In the 1970s, with the rapid development of the foundry industry, purity requirements for cast zinc alloys continued to rise. Different manufacturers had varying definitions and control standards for purity, resulting in inconsistent product quality on the market. To standardize the market and improve the quality stability of cast zinc alloys, the German Institute for Standardization (DVN) convened a large group of industry experts, researchers, and company representatives. After years of research and implementation, the DIN 743-78 standard was officially released in 1978, providing a scientific and unified basis for the production and application of pure cast zinc alloys.

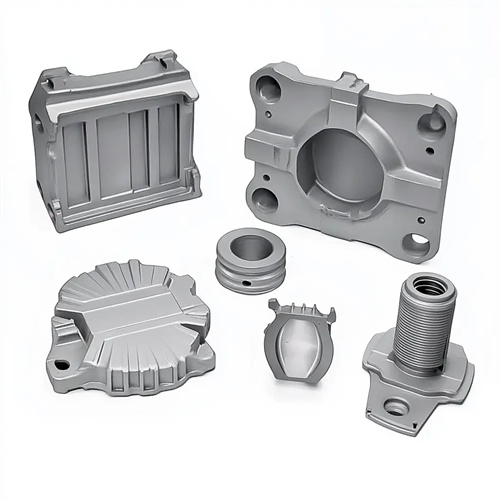

The DIN 743-78 standard clearly defines and categorizes pure cast zinc alloys, providing a unified language for communication and transactions within the industry. This standard defines pure cast zinc alloys as alloy materials primarily composed of zinc, produced through a specific casting process, and with impurity levels controlled within a specified range. Based on the zinc content and the type and concentration of the main alloying elements, the standard classifies pure cast zinc alloys into multiple categories, each with unique performance characteristics and application areas. For example, some categories offer high strength and hardness, suitable for manufacturing components subject to high loads; others, with excellent corrosion resistance and fluidity, are suitable for the production of complex castings. This clear classification enables companies to select the appropriate zinc alloy type based on their specific needs, improving targeted production efficiency.

The DIN 743-78 standard has extremely strict purity requirements, which is one of its core contents. It clearly defines the maximum permissible levels of various impurity elements, such as lead, cadmium, iron, and copper. While these impurities may be present in trace amounts in zinc alloys, excessive amounts can severely impact the alloy’s performance, such as reducing its mechanical properties, corrosion resistance, and casting properties. For example, excessive lead can cause hot brittleness in zinc alloys, shortening the lifespan of castings; while excessive iron content increases the alloy’s hardness and reduces its machinability. Therefore, the standard strictly controls the levels of these impurities, requiring manufacturers to utilize advanced smelting and purification technologies to ensure that the zinc alloy’s purity meets the standard requirements. The standard also specifies corresponding purity testing methods to ensure the accuracy and reliability of the test results.

The DIN743-78 standard also provides detailed regulations for the casting process and performance indicators of pure cast zinc alloys. In terms of casting technology, the standard defines key parameters such as temperature control, pouring speed, and mold design during the casting process. The reasonable control of these parameters directly affects the quality of the casting. For example, too high a casting temperature may cause oxidation and burning of the zinc alloy, increasing the impurity content; while too low a temperature will affect the fluidity of the zinc alloy, resulting in defects such as insufficient pouring and cold shut in the casting. In terms of performance indicators, the standard stipulates mechanical performance indicators such as tensile strength, elongation, and Brinell hardness of pure cast zinc alloys, as well as performance indicators such as corrosion resistance and wear resistance. Manufacturers need to implement strict process control and quality testing to ensure that their products can meet these requirements.

The implementation of the DIN 743-78 standard has had a positive and profound impact on Germany’s zinc alloy casting industry. On the one hand, it has significantly improved the quality of Germany’s high-purity cast zinc alloys, giving German-produced zinc alloy castings a strong reputation and competitiveness in the international market, becoming synonymous with high quality. On the other hand, the unified standard has also promoted technical exchange and cooperation within the industry, driving continuous innovation and progress in casting processes and purification technologies. For manufacturers, adhering to the DIN 743-78 standard not only improves product quality and stability, but also reduces production costs, increases production efficiency, and enhances market competitiveness. For downstream industries such as automotive manufacturing, machining, and electronics and electrical appliances, using pure cast zinc alloys that meet this standard can effectively guarantee the performance and reliability of their products, providing a solid material foundation for the high-quality development of the entire industrial system.