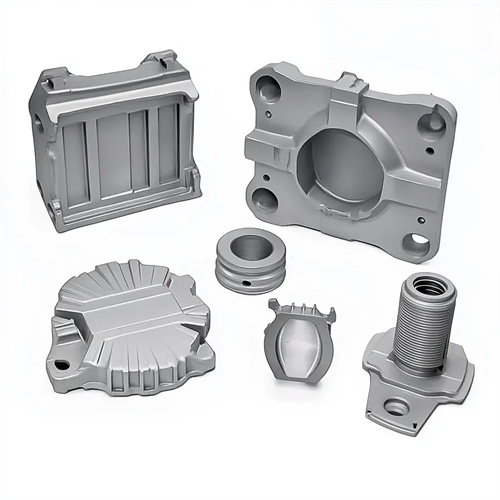

American standard ASTMB86-96 alloy castings and die castings

As a key specification for alloy castings and die-castings, the American standard ASTM B86-96 provides comprehensive and detailed technical guidance for the production, inspection, and application of these products in the United States and globally. Its broad scope of application covers castings and die-castings made from a variety of alloy materials. Whether common aluminum alloys, zinc alloys, or other specialized alloys, the standard provides corresponding technical requirements, playing an irreplaceable role in ensuring consistent and reliable product quality.

ASTM B86-96 provides a clear and systematic classification of alloy materials and designations. The standard categorizes alloy castings and die-castings into multiple categories and designations based on the chemical composition and performance characteristics of each alloy, and clearly defines the content of key alloying elements for each designation. For example, for aluminum alloy castings, the standard specifies the content ranges of elements such as silicon, copper, and magnesium; for zinc alloy die-castings, the ratios of zinc, aluminum, and copper are clearly defined. This detailed classification not only facilitates manufacturers in selecting appropriate alloy materials based on product requirements but also provides a clear basis for downstream users to select materials, ensuring that the selected castings and die-castings meet specific performance requirements. Furthermore, the standard strictly limits the content of impurity elements in each alloy designation to prevent impurities from adversely affecting product performance.

Performance requirements are one of the core contents of ASTM B86-96, covering multiple aspects such as mechanical properties and physical properties. In terms of mechanical properties, the standard specifies corresponding tensile strength, yield strength, elongation, hardness, and other indicators for different grades of alloy castings and die-castings. These indicators are formulated based on a large amount of test data and practical application experience, and can meet the strength, toughness, wear resistance, and other requirements of products in different industries. For example, alloy castings used in the aerospace field need to have extremely high tensile strength and toughness to cope with extreme environments; while die-castings in some everyday consumer products may place greater emphasis on surface hardness and a certain level of strength. In terms of physical properties, the standard also stipulates the density, melting point, thermal conductivity, electrical conductivity, and other characteristics of alloy castings and die-castings to ensure that the products can function properly in specific working environments.

Standardization of inspection methods is a key link in ensuring product quality according to ASTM B86-96. The standard specifies in detail the operating procedures and technical requirements for various inspection methods, including chemical composition analysis, mechanical property testing, and non-destructive testing. In chemical composition analysis, high-precision detection methods such as spectral analysis and chemical titration are recommended to ensure that the content of each element in the alloy can be accurately determined. Mechanical property testing has strict regulations on the preparation of specimens, the accuracy of test equipment, and the conditions of the test environment to ensure the accuracy and comparability of test results. For the internal and surface quality of castings and die-castings, the standard recommends the use of non-destructive testing methods such as ultrasonic testing, radiographic testing, and penetrant testing, which can effectively detect internal defects such as cracks, shrinkage cavities, and pores, as well as surface scratches, dents, and other problems, to ensure that unqualified products do not enter the market.

Quality control and acceptance rules are crucial for ensuring product quality in ASTM B86-96. The standard clearly defines the items, frequency, and criteria for factory inspection and type testing of alloy castings and die-castings. Factory inspection is a routine test conducted on each batch of products, primarily including spot checks of chemical composition, mechanical properties, surface quality, and other items to quickly determine whether the product meets basic quality requirements. Type testing is a comprehensive inspection conducted after product design finalization, major changes to the production process, or replacement of raw materials. It covers all technical indicators specified in the standard to verify the stability and reliability of product quality. The standard also requires manufacturers to establish a comprehensive quality traceability system, recording every step of the production process to ensure that product quality issues can be traced back to the source and resolved promptly. For products that fail inspection, the standard specifies options such as rework and scrapping to maintain the rigor of the standard and market order.