International Standard ISO 338997 Chemical Composition and Mechanical Properties of Cast Copper Alloys

International Standard ISO 338 997, a key global specification for cast copper alloys, was developed to provide a unified technical basis for the production, trade, and application of cast copper alloys in various countries. Against the backdrop of accelerating globalization, differences in cast copper alloy standards exist across countries and regions, causing numerous inconveniences for international trade and impacting the efficient circulation of cast copper alloys in the international market. To eliminate these technical barriers, the International Organization for Standardization (ISO) convened experts, scholars, business representatives, and research institutes from around the world. After years of research, experimentation, and demonstration, the ISO 338 997 standard was officially released in 1997. This standard focuses on the chemical composition and mechanical properties of cast copper alloys, laying a solid foundation for the standardized development of the global cast copper alloy industry.

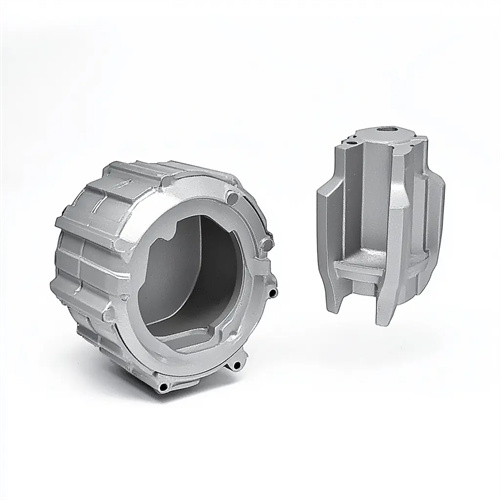

The ISO 338 997 standard clearly defines the scope of application for cast copper alloys, covering a wide range of cast copper alloy products. Copper alloy castings, whether produced using different casting processes such as sand casting, metal mold casting, or centrifugal casting, are included in the standard’s scope of regulation as long as their primary purpose relies on their chemical composition and mechanical properties to meet the requirements of their intended use. From precision parts in the aerospace field to general components in the machinery manufacturing industry, from conductive components in electronic and electrical equipment to corrosion-resistant elements in the chemical industry, the ISO 338 997 standard provides unified quality assessment criteria. This has greatly promoted the integrated development of the global cast copper alloy market and facilitated technical exchanges and trade between companies from various countries.

In terms of chemical composition, the ISO338 997 standard has made extremely detailed and strict regulations. The standard clearly defines the content range of main elements and impurity elements in each alloy according to different types of cast copper alloys, such as brass, bronze, and white copper. For example, for tin bronze, the standard stipulates the tin content range, and strictly limits the maximum allowable content of impurity elements such as lead, iron, and phosphorus. These regulations are not formulated out of thin air, but are based on a large amount of experimental data and practical application experience, aiming to ensure that cast copper alloys have stable performance. Reasonable chemical composition is the prerequisite for cast copper alloys to achieve excellent mechanical properties, corrosion resistance and processing performance. Manufacturers must use precise ingredients and strict smelting process control to ensure that the chemical composition of the product meets the standard requirements, laying the foundation for subsequent performance assurance.

Mechanical properties are another core content of the ISO338 997 standard. The standard sets clear numerical requirements for a number of mechanical properties of different types of cast copper alloys. Indicators such as tensile strength, yield strength, elongation, and hardness are all included in the specification range, and the requirements for these indicators vary depending on the alloy grade and casting process. For example, for cast copper alloys used to withstand high loads, the tensile strength and yield strength requirements are relatively high; while for castings that require plastic processing, elongation becomes an important consideration. In order to ensure the accuracy and consistency of mechanical property testing, the standard also makes detailed provisions for sample preparation methods, test environment conditions, and testing equipment accuracy to ensure that the results of tests by different laboratories and companies are comparable and credible.

The implementation of the ISO 338997 standard has had a profound impact on the global cast copper alloy industry. On the one hand, it has unified global quality standards for cast copper alloys, lowered technical barriers to international trade, facilitated the free flow of cast copper alloys worldwide, and created favorable conditions for companies from all over the world to expand into the international market. By adhering to this standard in production, companies in many countries have gained international recognition for their product quality and enhanced their international competitiveness. On the other hand, the implementation of the standard has promoted advancements in cast copper alloy production technology. To meet the requirements of the standard, companies have continuously improved production processes, introduced advanced equipment, and strengthened quality control, thereby improving the technical level and product quality of the entire industry. For downstream users, using cast copper alloys that comply with the ISO 338997 standard can effectively reduce procurement risks, ensure product quality stability and reliability, and promote the healthy development of related industries.