Design of Die Casting Die for Covers

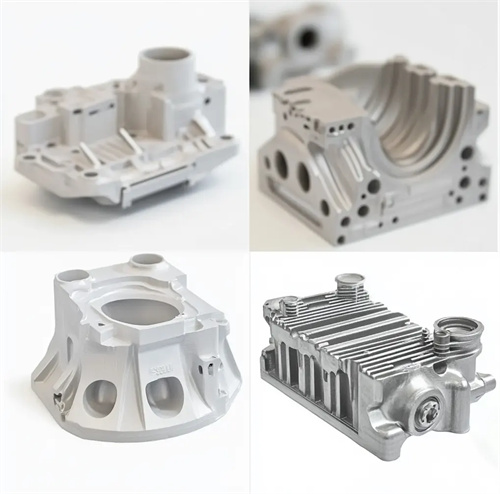

Cover-type die-castings are widely used in the automotive, electrical, and mechanical industries, such as engine end covers, motor end covers, and instrument housing covers. These parts usually have high requirements for flatness, strict assembly precision, and good appearance quality. Therefore, the design of die-casting molds for covers needs to revolve around these requirements. In the early stages of design, the functional requirements of cover-type parts need to be clarified. For example, the sealing cover needs to have good sealing performance, and the mold design needs to ensure the flatness and roughness of the sealing surface; the decorative cover has extremely high requirements for appearance quality, and the mold cavity surface needs to be polished with high precision. At the same time, the structural characteristics of cover-type parts need to be analyzed. Most cover-type parts are disc-shaped or square, with flange edges, mounting holes, and protrusions. The mold design needs to consider the molding method and demolding feasibility of these structures, and formulate a reasonable design plan based on the properties of the die-casting alloy, such as fluidity and shrinkage characteristics.

The structural design of die-cast lid-type molds requires special attention to parting surface selection and demolding mechanism design. Since lid-type parts are often flat, the parting surface is typically selected at the part’s largest contour to simplify the mold structure and ensure part flatness. For lid-type parts with deep cavities or undercuts, lateral core pulling mechanisms, such as inclined guide pin core pulling or hydraulic core pulling, may be necessary to ensure smooth molding and demolding of the undercuts. The runner system must be designed to ensure smooth filling of the cavity by the molten metal, avoiding impact on thin-walled areas of the part. Center gates or ring gates are typically used to evenly distribute the molten metal from the center to the periphery, reducing turbulence and air entrainment during filling. For large lid-type parts, multi-point symmetrical gates can be used to ensure consistent filling speeds across all areas. A venting system should be located at the final filling point, such as the flange edge or the base of a raised structure. The venting groove should be 0.05-0.1mm deep and its width determined by the cavity size to ensure timely discharge of trapped gas and prevent the formation of blowholes and cold shut defects.

The choice of mold material depends on the material and production volume of the die-cast lid. Lid die-castings are primarily made of aluminum alloys, zinc alloys, and other materials. While the die-casting temperature is relatively low, the mold surface quality requirements are high. For mass-produced lid molds, the cavity material is typically H13 hot-work die steel. This material offers excellent polishing properties and wear resistance, and after heat treatment, it can reach a hardness of 42-46 HRC, meeting the needs of long-term production. For zinc alloy lid molds, due to the lower die-casting temperature, Cr12MoV cold-work die steel can also be used. After quenching and tempering, it can reach a hardness of 58-62 HRC and exhibits high dimensional stability. Surface treatment of the mold cavity is crucial. For lids with high aesthetic requirements, the cavity surface should be polished to Ra 0.02-0.04μm, and chrome plating should be applied if necessary to improve surface hardness and finish, thereby reducing surface scratches and sticking. High-strength steel is used for guide components and ejection mechanisms to ensure stable and reliable operation.

Die-cast lid parts require stringent dimensional accuracy and form/position tolerances, necessitating meticulous mold design. Flatness is a key performance characteristic of lid parts, typically controlled within 0.1mm/m. The flatness of the mold parting surface must be controlled within 0.01mm/m to ensure part flatness. Mounting holes require high positional accuracy, typically within a ±0.05mm tolerance. The corresponding molding cores in the mold require precise positioning, such as using locating pins to maintain a positional tolerance of within 0.02mm. Mold dimensional design must consider the alloy’s shrinkage. This shrinkage must be accurately calculated based on the structure and alloy type of the lid part. For example, the shrinkage of aluminum alloy lid parts is generally 0.9%-1.1%, requiring the mold cavity dimensions to be increased accordingly. The guide mechanism utilizes precision guide pins and bushings, with a clearance of 0.005-0.01mm to ensure precise mold closing and avoid flash or dimensional deviation caused by mold misalignment. In addition, the ejection mechanism of the mold needs to be evenly distributed, and the ejection points should be selected at the rigid parts of the parts, such as flange edges and reinforcing ribs, to avoid deformation of the parts during ejection.

As die-cast lid parts evolve toward lightweighting, integration, and high precision, mold design technology is constantly innovating. CAE simulation technology is widely used in lid mold design. By simulating the molten metal filling process, it can optimize the design of gates and venting systems and predict potential defects such as porosity and shrinkage, thereby improving mold design reliability. For example, for decorative lids with complex patterns, simulation can ensure that the patterned area is fully filled with molten metal, ensuring a high-quality appearance. Mold cooling system design is becoming more refined, with the use of annular or conformal cooling channels to achieve uniform cavity temperature distribution, shorten part solidification time, improve production efficiency, and reduce part deformation caused by temperature variations. Rapid prototyping technologies, such as 3D printing, can be used to create mold cavity prototypes for trial mold verification, shortening mold development cycles. Furthermore, the concept of intelligent mold design is gaining popularity. Sensors are embedded in the mold to monitor parameters such as temperature and pressure during the die-casting process in real time. Process parameters are adjusted through feedback systems to ensure consistent quality of lid die-cast parts, providing a strong guarantee for the high-quality production of lid parts.