Design of Die Casting Dies for Motorcycles

The design of motorcycle die-casting molds is a crucial component of the motorcycle manufacturing industry, directly impacting the performance, safety, and appearance of the motorcycle. Motorcycle die-castings encompass a wide variety of components, including frame components, engine housings, wheels, shock absorber components, and covers. These components must not only possess sufficient strength and rigidity to withstand the various loads encountered during driving, but also meet requirements for lightweightness and aesthetics, thus presenting diverse challenges for mold design. Initial design stages require a comprehensive understanding of the motorcycle’s operating environment and the functional requirements of the die-castings. For example, frame components require high strength and fatigue resistance to ensure safe driving; engine housings require excellent sealing and heat dissipation to prevent oil leakage and engine overheating; and covers require superior appearance quality to enhance the motorcycle’s overall aesthetics. Targeted mold design solutions are developed based on the characteristics of each component to ensure that the die-castings meet various performance specifications.

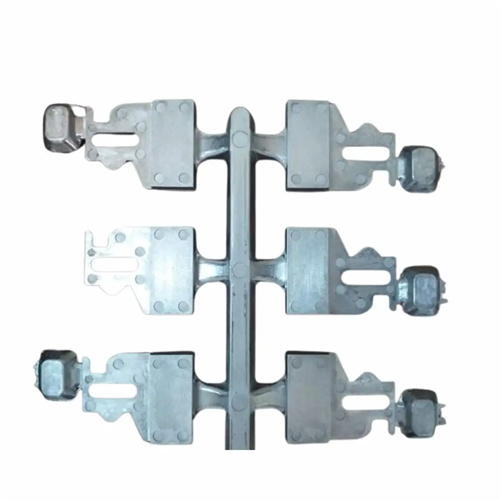

The structural design of motorcycle die-casting molds requires careful planning based on the shape and structural characteristics of the die-casting. Frame components are often irregularly shaped, tubular, or box-shaped, with thin, unevenly distributed wall thicknesses. Therefore, the mold design requires a rational parting scheme, typically a combination of vertical and horizontal parting, to ensure smooth die-casting and demolding. To enhance the strength of the frame, certain areas are designed with reinforcing ribs. The mold cavity must precisely shape these ribs, while also ensuring proper filling of the molten metal within the ribs to avoid defects such as underfill and air bubbles. The engine housing is a complex structure, with internal cavities for oil and water channels. The mold design requires a mosaic structure, breaking the complex cavity into multiple simple core and cavity modules for ease of processing and assembly. The runner system must be designed to ensure uniform and rapid filling of the molten metal into each cavity. For multi-cavity molds, a balanced runner is required to ensure consistent filling time and pressure across all cavities. An exhaust system should be installed at the final filling point and corners of the cavity to ensure the timely discharge of trapped gases, thereby enhancing the density of the die-casting.

The selection of mold materials requires a comprehensive consideration of the material, production volume, and performance requirements of the motorcycle die-casting parts. Common materials for motorcycle die-castings include aluminum alloys and magnesium alloys. These materials have relatively low die-casting temperatures, but production batches are typically large. Therefore, the mold material must possess excellent wear resistance and fatigue resistance. For aluminum alloy die-casting molds, H13 hot-work die steel is a common choice. After proper heat treatment, this material can achieve a hardness of 42-48 HRC, meeting the demands of high-volume production. For magnesium alloy die-casting molds, because magnesium alloys readily react with the mold material at high temperatures, the mold surface requires special treatment, such as nitriding or an anti-stick coating, to reduce adhesion between the mold and the molten metal and extend the mold’s lifespan. For panel molds with high aesthetic requirements, the cavity surface is polished to a surface roughness of less than Ra0.04μm to ensure the surface quality of the die-casting. Furthermore, the mold’s template and guide components must be constructed of high-strength steel to ensure overall rigidity and stability.

The dimensional accuracy and form-to-position tolerance requirements for motorcycle die-castings vary depending on the component, necessitating precise mold design to match these requirements. Frame components require high dimensional accuracy, particularly the hole tolerance and flatness of joints. Hole tolerances are typically controlled within ±0.05mm, and flatness errors are controlled within 0.1mm/m to ensure accurate and reliable assembly. Mold design requires high-precision machining equipment and measuring instruments to ensure the dimensional accuracy of the mold cavity and core. Stringent dimensional accuracy requirements apply to areas such as the bearing holes and sealing surfaces of the engine housing. The roundness error of the bearing holes must be controlled within 0.005mm, and the flatness error of the sealing surfaces must be controlled within 0.01mm. These areas of the mold require even higher machining accuracy to ensure the die-casting meets the required sealing and rotational accuracy. For high-speed rotating parts such as wheels, dynamic balancing performance is crucial. The mold design must ensure uniform wall thickness of the wheel to avoid affecting dynamic balance due to uneven mass distribution. The mold cavity and core must have good symmetry, and strict symmetry testing is required during the processing process.

With the continuous development of the motorcycle industry, demands for motorcycle performance, environmental friendliness, and appearance are becoming increasingly stringent, driving continuous advancements in die-casting mold design technology. The application of CAE simulation technology in mold design enables designers to simulate and analyze the die-casting process before mold manufacturing, optimizing mold structure and process parameters, reducing mold trials and improving mold design efficiency and quality. For example, by simulating the molten metal filling process, gate location and size can be optimized to ensure smoother metal flow and minimize eddy currents and air entrainment. Simulating the solidification process can optimize cooling system design, improve cooling efficiency, and reduce deformation and shrinkage defects in die-cast parts. Rapid mold prototyping technologies, such as 3D printing, enable the rapid creation of mold prototypes, cores, and cavities, shortening mold development cycles and facilitating rapid verification and modification of mold designs. Furthermore, intelligent mold design is a future trend. By integrating sensors and control systems into the mold, parameters such as temperature and pressure can be monitored in real time during the die-casting process, enabling timely adjustment of process parameters to ensure consistent quality of die-cast parts. The application of these technologies provides strong support for the high-quality and high-efficiency design of motorcycle die-casting molds, and promotes the sustainable development of the motorcycle manufacturing industry.