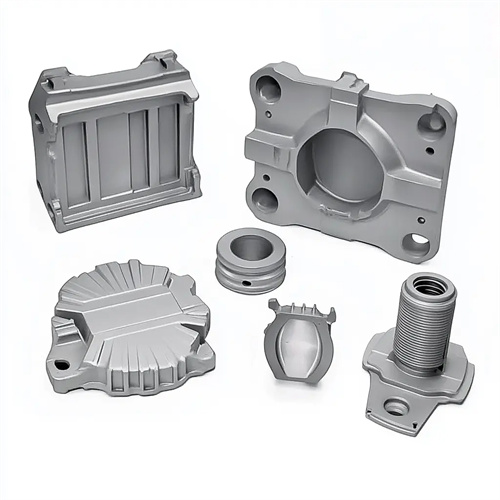

Die casting surface shape and position

The surface shape and positional accuracy of die-castings are important indicators of their quality, directly affecting the assembly performance, appearance quality, and functional realization of parts. Surface shape accuracy refers to the degree of conformity between the actual geometric shape of the die-casting surface and the ideal geometric shape, such as flatness, roundness, cylindricity, etc.; positional accuracy refers to the positional deviation of the part surface or axis relative to the reference plane or reference axis, such as parallelism, perpendicularity, coaxiality, etc. In the fields of precision machinery, automobile manufacturing, aerospace, etc., extremely high requirements are placed on the surface shape and positional accuracy of die-castings. Even slight deviations may lead to assembly failure or equipment malfunction. For example, if the flatness of the engine cylinder block does not meet the requirements, it may lead to poor sealing, oil leakage, air leakage, and other problems, seriously affecting the performance and service life of the engine.

There are many factors that affect the surface shape and positional accuracy of die-castings, and mold design and manufacturing are key links. The mold cavity shape, parting surface accuracy, guide mechanism accuracy, etc. directly determine the surface shape and positional accuracy of the die-casting. If the machining accuracy of the mold cavity is insufficient, such as excessive flatness error or uneven arc surface, the surface shape accuracy of the die-casting will inevitably be affected. If there are problems such as excessive clearance or wear in the mold guide mechanism, the relative position of the movable mold and the fixed mold will deviate when the mold is closed, which in turn affects the positional accuracy of the die-casting. For example, if the fitting clearance between the mold guide pin and the guide sleeve exceeds the specified value, the coaxiality error of the die-casting will increase and it will not meet the assembly requirements. Therefore, during the mold design and manufacturing process, high-precision processing equipment and advanced testing methods must be used to ensure the shape accuracy of the mold cavity and the positional accuracy of the guide mechanism, providing a basic guarantee for the surface shape and positional accuracy of the die-casting.

Controlling die-casting process parameters significantly impacts the surface shape and positional accuracy of die-cast parts. Improper settings of parameters such as injection speed, injection pressure, mold temperature, and pouring temperature can cause deformation in die-cast parts, thereby affecting their surface shape and positional accuracy. Excessively fast injection speeds cause violent impacts of the molten metal in the mold cavity, generating significant internal stress within the casting. This can lead to warping after cooling and compromised flatness or perpendicularity. Insufficient injection pressure results in inadequate filling of the casting with molten metal, resulting in localized depressions or protrusions in the casting, affecting surface shape accuracy. Uneven mold temperature distribution is also a significant cause of casting deformation. If the temperature in one area of the mold is too high, the casting in that area cools more slowly and shrinks more than other areas, leading to bending and loss of positional accuracy. Therefore, in die-casting production, process parameters must be optimized based on the structural characteristics and alloy type of the casting to maintain a uniform mold temperature, minimize deformation, and ensure surface shape and positional accuracy.

The structural design of castings also has a significant impact on surface shape and positional accuracy. If the structural design of the die-casting is unreasonable, such as uneven wall thickness, sharp corners or slender structures, the casting will shrink unevenly during the cooling process, causing deformation and affecting the surface shape and positional accuracy. For example, a die-casting with a slender cantilever will shrink more during cooling, which can easily cause bending and lead to excessive perpendicularity with the reference plane. Therefore, when designing the structure of a casting, the principle of equal wall thickness should be followed to avoid sudden changes in wall thickness. For any necessary wall thickness differences, a gradual transition should be adopted. At the same time, sharp corners and slender structures should be reduced, and reinforcing ribs should be added when necessary to increase the rigidity of the casting and reduce deformation. Reasonable structural design can reduce the risk of casting deformation and create favorable conditions for ensuring surface shape and positional accuracy.

Inspection and corrective measures are crucial for ensuring the surface shape and positional accuracy of die-castings. During the production process, high-precision testing instruments are required to inspect the surface shape and positional accuracy of die-castings. For example, a three-dimensional coordinate measuring machine (CMM) is used to check flatness, perpendicularity, and coaxiality, and a roundness gauge is used to check roundness and cylindricity. If castings are found to have out-of-tolerance defects during inspection, the cause must be analyzed and corrective measures implemented. If mold wear causes a decrease in accuracy, the mold should be repaired or replaced. If deformation is caused by improper process parameters, these parameters must be optimized. If the casting’s structural design causes out-of-tolerance defects, the design department should be consulted to improve the structure. Furthermore, for die-castings requiring extremely high precision, aging treatment can be performed after die-casting to eliminate internal stresses and reduce deformation. Alternatively, minor machining can be performed to correct surface shape and positional errors to meet operational requirements. A comprehensive inspection and correction system can effectively control the surface shape and positional accuracy of die-castings, ensuring they meet assembly and operational requirements.