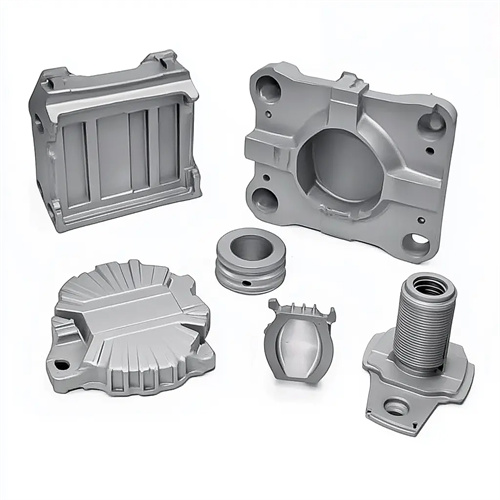

Die-cast aluminum silicon alloy

Die-cast aluminum silicon alloy is an important type of die-cast aluminum alloy. With its unique composition and performance characteristics, it has shown significant advantages in many industrial fields and has become a key material for manufacturing high-performance die-casting parts.

In aluminum-silicon alloys, silicon is the primary alloying element, and its content has a decisive influence on the alloy’s properties. Generally speaking, the silicon content of die-cast aluminum-silicon alloys ranges from 7% to 13%. When the silicon content is low, the alloy exhibits excellent ductility, making it suitable for deformation processing; whereas, when the silicon content is high, the fillability of the alloy melt is significantly improved, making die-cast aluminum-silicon alloys outstanding in the casting field. A higher silicon content can lower the alloy’s crystallization temperature range and increase the eutectic content, significantly improving the alloy’s fluidity. This allows it to quickly and evenly fill complex mold cavities during high-pressure die-casting, reducing casting defects and improving the dimensional accuracy and surface quality of the castings.

Die-cast aluminum-silicon alloys possess excellent casting properties, a key foundation for their widespread application. Compared to other aluminum alloys, they are less prone to hot cracking and shrinkage. During the casting process, hot cracking is a crack defect caused by thermal stress generated during solidification exceeding the material’s strength limit. Shrinkage is a tiny hole formed when the alloy’s volumetric shrinkage during solidification is not effectively compensated. The presence of silicon in die-cast aluminum-silicon alloys reduces the alloy’s susceptibility to hot cracking. Furthermore, their solidification characteristics facilitate shrinkage compensation, reducing the occurrence of shrinkage defects and enabling the production of higher-quality, more compact die-cast parts.

Die-cast aluminum-silicon alloys have found widespread and significant application in the automotive industry. Key components of automotive engines, such as cylinder blocks, cylinder heads, and pistons, are often manufactured from die-cast aluminum-silicon alloys. For example, aluminum-silicon alloys with a silicon content of 11% to 13% are ideal for pistons due to their lightweight, low coefficient of expansion, and high corrosion resistance. During engine operation, pistons must withstand the harsh conditions of high temperatures, high pressures, and high-speed reciprocating motion. Pistons made from die-cast aluminum-silicon alloys can effectively reduce engine weight, lower inertia, and improve efficiency and reliability. Furthermore, their excellent wear and corrosion resistance ensures stable performance over long-term use.

Die-cast aluminum-silicon alloys also play a vital role in the aerospace sector. Aircraft components place extremely high demands on material performance, requiring them to maintain high strength while minimizing weight. Die-cast aluminum-silicon alloys meet these stringent requirements through optimized alloy composition and manufacturing processes. For example, some aircraft engine components are manufactured using die-cast aluminum-silicon alloys, leveraging their low density and high strength to reduce engine weight and improve aircraft performance and fuel economy. Furthermore, the excellent casting properties of die-cast aluminum-silicon alloys enable the manufacture of complex-shaped components, meeting the diverse demands of component structural design in the aerospace sector.

In recent years, with the continuous advancement of science and technology, significant progress has been made in the research and development of heat-treatment-free, high-strength and toughness die-cast aluminum-silicon alloys. These alloys possess high strength and toughness in the die-cast state, eliminating the need for traditional heat treatment. This not only reduces production steps and costs, but also avoids problems such as dimensional deformation of die-cast parts caused by heat treatment. For example, near-eutectic heat-treatment-free, high-strength and toughness die-cast aluminum-silicon alloys such as JS3 and JS2, as well as the hypoeutectic heat-treatment-free, high-strength and toughness YS2 die-cast aluminum-silicon alloy, offer excellent overall performance and are suitable for both conventional thin-walled die-castings and large, integrated die-castings. They hold broad application prospects in a wide range of fields, including construction, automotive, lighting, aircraft, and household appliances.

In summary, die-cast aluminum-silicon alloys, with their unique performance advantages, occupy an indispensable position in key industrial fields such as automobiles and aerospace, as well as in emerging material application fields. With the continuous development of materials science, the performance of die-cast aluminum-silicon alloys will continue to improve, and the scope of their application will continue to expand, providing strong support for technological innovation and development in various industries.