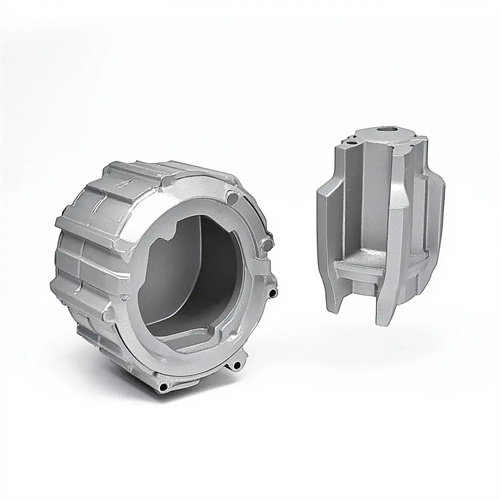

die-cast aluminum alloy

As a key material in the die-casting industry, die-cast aluminum alloys hold a crucial position in modern industrial production due to their unique performance advantages. Using aluminum as a base material and various alloying elements, die-cast aluminum alloys are used to create a variety of high-precision, high-performance components for a wide range of applications across numerous industries.

From a performance perspective, die-cast aluminum alloys offer excellent overall properties. First, their relatively low density of approximately 2.7 g/cm³ makes die-cast parts lightweight, making them ideal for weight-critical industries such as the automotive and aerospace sectors. Second, die-cast aluminum alloys possess high strength and hardness, meeting the operational requirements of components under diverse operating conditions. They also exhibit excellent corrosion resistance, maintaining stable performance in natural environments or in specific corrosive media, extending component life. Furthermore, die-cast aluminum alloys offer excellent casting properties and fluidity, enabling them to quickly fill mold cavities under high pressure, forming complex castings. These castings also exhibit high dimensional accuracy and excellent surface quality, reducing the need for subsequent processing steps.

Die-cast aluminum alloys are widely used in the automotive industry. Key components of automotive engines, such as cylinder blocks, cylinder heads, and transmission housings, are largely made of die-cast aluminum alloys. As a core engine component, the cylinder block requires high strength and excellent heat dissipation. Die-cast aluminum alloys precisely meet these requirements, reducing engine weight while improving efficiency and reliability. Wheels are also a key application area for die-cast aluminum alloys. Aluminum alloy wheels are not only lightweight, reducing the vehicle’s unsprung mass and improving handling, but also offer excellent appearance and corrosion resistance, making them popular with automakers and consumers. Furthermore, die-cast aluminum alloys are increasingly being used in automotive body structural components and interior trims, effectively reducing vehicle weight and reducing energy consumption.

Die-cast aluminum alloys also play a vital role in the electronics sector. As electronic products continue to become thinner, lighter, and smaller, the performance requirements for materials are becoming increasingly demanding. Die-cast aluminum alloys offer excellent strength and heat dissipation, making them an ideal material for electronic product casings. For example, the casings of mobile phones, tablets, and laptops are made of die-cast aluminum alloys, which not only protect the internal electronic components but also effectively dissipate heat generated during operation, ensuring stable operation. Furthermore, aluminum alloy casings can be treated with a variety of surface treatments, such as anodizing and painting, to enhance their aesthetic appearance and pleasant feel, thereby enhancing the product’s added value.

The aerospace industry places extremely stringent demands on material performance. Die-cast aluminum alloys, thanks to their lightweight and high-strength advantages, are widely used in this field. Aircraft engine components, fuselage structures, and landing gear may all be manufactured using die-cast aluminum alloys. For example, engine fan blades and compressor blades, for example, must operate at high speeds and high temperatures. By optimizing the alloy composition and manufacturing process, die-cast aluminum alloys can meet these components’ requirements for strength, high-temperature resistance, and fatigue resistance, while also reducing aircraft weight and improving flight performance and fuel economy.

In addition to the aforementioned industries, die-cast aluminum alloys also have extensive applications in machinery manufacturing, home appliances, medical devices, and other fields. In machinery manufacturing, they are used to manufacture various mechanical parts and tools; in the home appliance sector, they are commonly found in components for air conditioners, refrigerators, washing machines, and other products; and in medical devices, they are used to manufacture surgical instruments and medical device casings. With the continuous advancement of technology and the sustained development of industry, the performance of die-cast aluminum alloys will continue to improve, and their application areas will further expand, providing stronger support for the development of various industries.