Die casting simplifies molds and extends mold life

Molds are core equipment in die-casting production. Their structural complexity and service life directly impact the production cost and efficiency of die-castings. Simplifying the mold structure by streamlining the die-casting structural design is an effective way to extend the mold’s service life. Complex mold structures are not only difficult and costly to manufacture, but are also prone to failure during production, leading to accelerated mold wear and shortened lifespan. Therefore, the need for mold simplification should be fully considered during the die-casting design phase. By optimizing the casting structure, reducing mold complexity, and improving mold reliability and durability, production costs can be reduced and production efficiency improved.

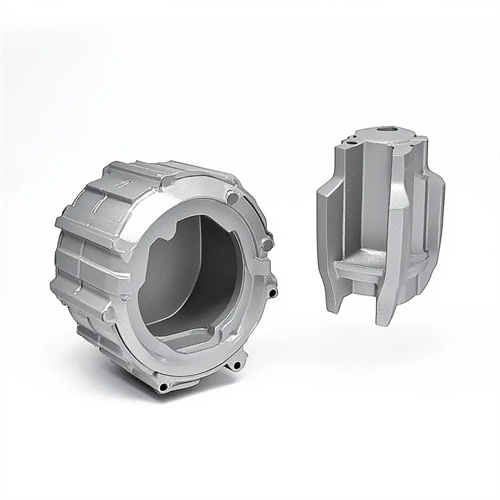

Reducing the number of mold parts is an important measure to simplify the mold structure. The mold parts include the core, cavity, inserts, etc. The more parts there are, the higher the assembly precision required for the mold, and the greater the probability of wear and failure during production. By optimizing the die-casting structure, integrating complex cavities and cores into a monolithic structure, and reducing the use of inserts and spliced structures, the mold can be significantly simplified. For example, for castings with multiple protrusions and depressions, if the dispersed protrusions can be designed as a continuous, monolithic structure, the number of mold cores can be reduced, avoiding assembly errors and wear caused by too many cores. At the same time, the integral core and cavity have greater rigidity, can withstand greater die-casting pressure, reduce deformation and damage, and extend the life of the mold.

Optimizing the design of a mold’s core-pulling mechanism can simplify the mold structure and improve mold reliability. The core-pulling mechanism is one of the most complex and fragile parts of a mold, especially complex lateral and oblique core-pulling mechanisms. These are not only difficult to manufacture but are also prone to problems such as jamming and wear during the core-pulling process. By improving the structure of die-cast parts and avoiding or reducing the number of core-pulling locations as much as possible, the use of core-pulling mechanisms can be reduced. For example, holes and grooves on the casting that are perpendicular to the die-casting direction can be designed to be parallel to the die-casting direction to avoid the need for lateral core-pulling mechanisms; and replacing complex curved surface structures with flat or simple curved surfaces can reduce the number of complex moving parts in the mold. In situations where a core-pulling mechanism is necessary, a core-pulling method with a simple structure and reliable operation should be used as much as possible, such as using oblique guide pin core-pulling instead of hydraulic core-pulling. This reduces the use of complex components such as hydraulic systems and reduces the risk of mold failure.

Optimizing the mold’s gating and exhaust system design can also simplify the mold structure and extend its service life. Complex gating systems (such as multiple gates and complex runners) increase mold processing difficulty and cause molten metal scouring within the runners, leading to accelerated mold wear. By optimizing the die-casting structure to adapt the casting’s shape to a simple gating system, such as a center gate or ring gate, the complexity of the runners can be reduced, making mold processing easier. The exhaust system design should be as simple and effective as possible. By properly positioning and numbering the exhaust slots, complex exhaust plugs and exhaust mechanisms can be avoided, reducing the number of vulnerable parts in the mold. For example, utilizing natural clearances such as the casting’s parting surface and push rod clearance for exhaust can reduce the need for additional exhaust structures and simplify the mold.

Improving the overall rigidity and strength of the mold is key to extending its lifespan, and simplifying the mold structure can help improve this rigidity. Complex mold structures often have weak links, which can easily cause deformation and stress concentration during the high-pressure die-casting process, leading to mold cracking. By simplifying the mold structure, eliminating unnecessary holes, slots, and weak areas, and increasing the thickness and size of the mold plate and the molded parts, the overall rigidity of the mold can be improved. For example, using a monolithic mold instead of a split mold can increase the mold’s load-bearing capacity and reduce deformation caused by gaps between the molds. Furthermore, the simplified mold structure provides more uniform stress distribution, better able to withstand the high pressure and impact of the die-casting process, reduce mold fatigue damage, and extend its service life.

Rational selection of mold materials and optimized heat treatment processes, combined with a simplified mold structure, can further extend mold life. A simplified mold structure reduces complex molding parts and weak areas, allowing the mold material’s performance to be more fully utilized. For simplified molds, high-strength, high-wear-resistant hot-work die steels such as H13 and 3Cr2W8V can be selected, and appropriate heat treatment processes, such as quenching and tempering, can be employed to improve the mold’s hardness and toughness. At the same time, a simplified mold structure facilitates surface treatments such as nitriding and PVD coating, which improve the mold’s surface wear resistance and corrosion resistance and reduce wear and corrosion damage. Through the coordinated optimization of materials, heat treatment, and structural design, the mold’s service life can be significantly extended while simplifying its structure.