Die casting expansion force

The bulging force of a die-cast part refers to the outward expansion force exerted on the mold cavity walls by the molten metal after filling the mold cavity during the die-casting process. It is a crucial factor in mold design and die-casting machine selection. The magnitude of this bulging force directly determines the required clamping force. Insufficient clamping force can cause the mold parting surface to expand, leading to molten metal leakage, flash, and even mold damage. Excessive clamping force wastes energy and increases equipment investment costs. Therefore, accurately calculating bulging force and appropriately matching it are crucial for ensuring the safety, stability, and economic efficiency of die-casting production.

The magnitude of the expansion force is closely related to the pressure of the molten metal within the mold cavity, the projected area of the casting, and the pressure transmission efficiency. The calculation formula is: Expansion Force = Cavity Pressure × Projected Area of the Casting on the Parting Surface × Pressure Transmission Coefficient. Cavity pressure refers to the pressure exerted by the molten metal on the mold cavity walls. Its value is typically 50%-70% of the holding pressure, generally ranging from 30-100 MPa. The projected area of the casting on the parting surface refers to the maximum projected area of the casting perpendicular to the direction of the clamping force, including the area of the casting body, runner, and overflow channel, and is measured in square centimeters. The pressure transmission coefficient depends on the runner design and cavity structure and is generally between 0.8 and 0.9, with smaller values for complex cavities and larger values for simple cavities. For example, for an aluminum alloy casting with a projected area of 500 cm², a cavity pressure of 60 MPa, and a pressure transmission coefficient of 0.85, the expansion force is 60 × 500 × 0.85 = 25,500 kN.

Cavity pressure is the core factor affecting expansion force and is influenced by multiple factors, including injection force, holding pressure, and mold runner resistance. The injection force is transmitted to the mold cavity by the molten metal, generating cavity pressure. The greater the injection force, the higher the cavity pressure. Cavity pressure contributes most to expansion force during the holding phase because the molten metal has already filled the cavity, allowing pressure to fully act on the cavity walls. The resistance of the mold runner dissipates some of this pressure. The longer the runner and the smaller its cross-section, the greater the pressure loss, and the lower the cavity pressure. Therefore, when designing the mold runner, it is important to minimize runner length and increase runner cross-section while ensuring filling efficiency to reduce pressure loss and, in turn, lower expansion force. Furthermore, the temperature and viscosity of the molten metal also affect cavity pressure: When the temperature is too high, the viscosity is low, pressure loss is minimal, and cavity pressure is high; when the temperature is too low, the viscosity is high, pressure loss is high, and cavity pressure is low.

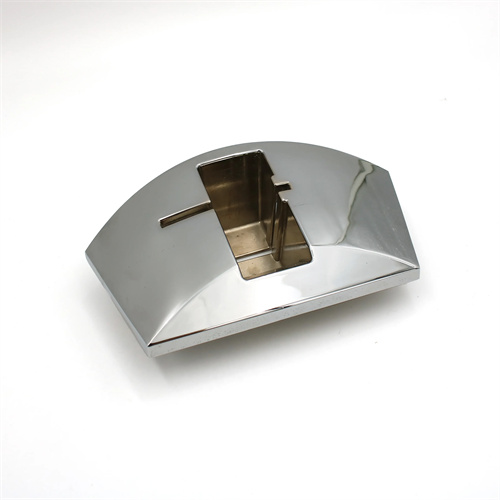

The influence of the structure and size of the casting on the expansion force is mainly reflected in the projected area. The larger the projected area, the greater the expansion force, so large die castings require a larger clamping force. For example, the projected area of a car engine cylinder block can reach 1500-2000cm², and its expansion force often exceeds 10,000kN, so a large die-casting machine needs to be selected. The complexity of the shape of the casting will also affect the distribution of the expansion force. Irregular-shaped castings will lead to uneven distribution of the expansion force, and excessive pressure may occur in local areas, thereby placing higher requirements on the local structural strength of the mold. For castings with structures such as deep cavities and bosses, in addition to the expansion force on the parting surface, lateral expansion force may also be generated, which needs to be balanced by the clamping force of the lateral core pulling mechanism to prevent the lateral parting surface of the mold from expanding.

The mold’s rigidity and strength must be designed to match the expansion force to prevent deformation or damage during the die-casting process. Mold parameters such as the mold plate thickness, cavity wall thickness, and number of support columns must all be calculated based on the expansion force. The mold plate thickness should generally be no less than 1/10 of the maximum projected dimension of the casting. For molds with high expansion forces, additional support columns should be added, with the combined cross-sectional area of the support columns no less than 1/5 of the projected area of the casting to distribute the expansion force and prevent mold plate deformation. The cavity wall thickness must be calculated based on the local expansion force to ensure it can withstand the pressure of the molten metal without plastic deformation. For example, for an aluminum alloy casting with a cavity pressure of 80 MPa, the cavity wall thickness should be no less than 15 mm. Stress concentration areas, such as corners, should be appropriately thickened or reinforced with ribs. The mold’s guide and clamping mechanisms must also be sufficiently strong to maintain precise closing positions under the influence of the expansion force.

The clamping force should be greater than or equal to the expansion force, with a safety margin of 10%-20%. Insufficient clamping force can lead to poor sealing at the mold parting surface, resulting in flash and affecting the dimensional accuracy of the casting. Leakage of molten metal can also damage the mold surface. Excessive clamping force increases the energy consumption of the die-casting machine, exacerbates wear on the die guide mechanism, and shortens the mold life. In actual production, the appropriateness of the clamping force can be verified through mold trials. If flash appears on the casting after a mold trial, the clamping force is insufficient and should be increased appropriately. If the clamping force is excessive, it can be reduced while ensuring no flash. Furthermore, the clamping force should be evenly distributed, matching the expansion force distribution to avoid localized insufficient or excessive clamping force. Modern die-casting machines utilize closed-loop clamping control systems that adjust the clamping force in real time based on changes in expansion force, ensuring that the clamping force remains within an appropriate range. This ensures both casting quality and energy efficiency.

In summary, expansion force is a crucial parameter that cannot be ignored in the die-casting process. It is closely related to factors such as cavity pressure, projected casting area, and mold structure. Accurately calculating expansion force, rationally designing mold strength, and selecting clamping force can ensure safe and stable die-casting production, improve product quality, and reduce production costs. With the development of die-casting technology, computer simulation technology can accurately predict the magnitude and distribution of expansion force, providing a more scientific basis for mold design and process parameter optimization, further promoting technological progress in the die-casting industry.