The die-casting filling time refers to the time it takes for the molten metal to completely fill the mold cavity from the moment it begins to enter the mold. It is an important parameter for measuring the efficiency of the die-casting process and the quality of the casting. The length of the filling time directly affects the flow state and solidification process of the molten metal in the mold cavity: a filling time that is too short will cause the molten metal to flow too quickly, forming turbulence, entraining air to produce pores, and may also increase wear due to severe impact on the mold; a filling time that is too long will cause the molten metal to overcool during the filling process, reducing its fluidity and making defects such as insufficient pouring and cold shut more likely to occur. For example, for thin-walled aluminum alloy castings, the filling time usually needs to be controlled between 0.03 seconds and 0.08 seconds to ensure that the molten metal fills the entire mold cavity before solidification; for thick-walled castings, the filling time can be appropriately extended to 0.1 seconds to 0.3 seconds to reduce the negative impact of turbulence.

The filling time setting needs to be determined comprehensively based on the structural characteristics of the casting, the alloy properties, and the mold design. The volume and wall thickness of the casting are the core factors affecting the filling time: the larger the volume and the thicker the wall, the longer the required filling time, because the molten metal takes longer to cover the larger space. At the same time, the heat dissipation in thick-walled areas is relatively slow, allowing a slightly longer filling process. Conversely, small and thin-walled castings require a shorter filling time to meet the challenge of rapid cooling. In addition, the fluidity of the alloy will also affect the choice of filling time. Alloys with good fluidity (such as zinc alloys) can maintain good filling capabilities for a slightly longer time, while alloys with poor fluidity (such as certain magnesium alloys) require a shorter filling time to avoid flow obstruction caused by cooling.

The pressurization build-up time refers to the time it takes from the moment the molten metal fills the mold cavity until the pressure reaches the set value during the pressurization phase. It plays a key role in compensating for shrinkage and increasing density in the die-casting process. If the build-up time is too short, the pressure cannot be transmitted to the interior of the mold cavity in a timely manner. The molten metal may have already begun to solidify, unable to effectively fill the voids caused by shrinkage, resulting in defects such as shrinkage and shrinkage cavities in the casting. If the build-up time is too long, the production cycle will be extended and production efficiency will be reduced. At the same time, the continuous high pressure may overload the mold, shortening its lifespan. For example, in aluminum alloy die-casting, the pressurization build-up time is typically controlled between 0.03 and 0.1 seconds to ensure timely pressure application while avoiding unnecessary time waste.

There is a close synergistic relationship between the filling time and the pressurization and pressure building time. The length of the filling time will directly affect the timing of the pressurization and pressure building: if the filling time is too short, the molten metal may still be in a turbulent state after filling the cavity. Immediate pressure building at this time will easily press bubbles into the interior of the casting, forming subcutaneous pores; if the filling time is too long, the molten metal has begun to solidify at the edge of the cavity, and the pressure is difficult to transmit to the center of the casting during pressure building, and shrinkage defects cannot be effectively eliminated. Therefore, it is necessary to reasonably set the delay time of the pressurization and pressure building according to the filling time to ensure that the pressure building is completed at the moment when the molten metal is about to solidify but still has a certain fluidity, so that the pressure can act evenly on the entire casting and improve its density. For example, for thin-walled castings with a filling time of 0.05 seconds, the pressurization and pressure building time can be set to 0.04 seconds to achieve seamless connection.

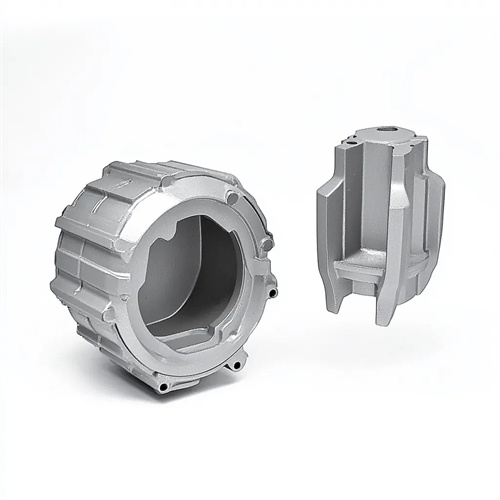

In actual production, optimizing filling and pressurization build times requires repeated process testing and data analysis. Modern die-casting machines’ real-time monitoring systems accurately record the actual filling and pressurization build times, allowing adjustments based on casting quality inspection results (such as X-ray inspection and mechanical property testing). Computer simulation technology also provides strong support for parameter optimization. By simulating the flow, solidification, and pressure transfer of molten metal under different filling and pressurization build times, potential defects can be predicted in advance, thereby shortening the process debugging cycle. For example, a company found through simulation that reducing the filling time of a certain aluminum alloy casing from 0.07 seconds to 0.05 seconds and adjusting the pressurization build time from 0.06 seconds to 0.04 seconds reduced the shrinkage rate of the casting by 30% and increased production efficiency by 15%. This data- and simulation-based optimization approach is a key path to achieving precision and efficiency in the die-casting process.