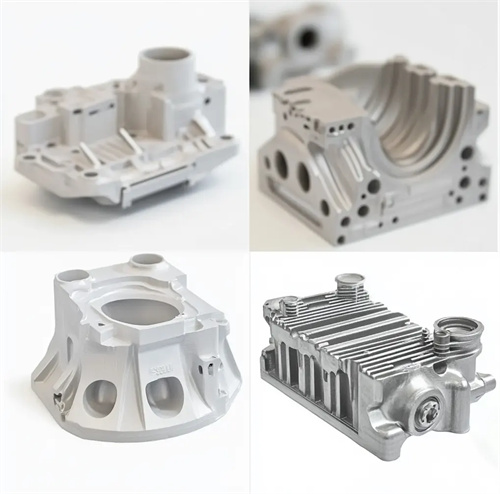

Design of die casting mold pouring system

The design of the die-casting mold gating system is one of the core aspects of die-casting mold design. It is responsible for smoothly and evenly introducing the molten metal from the pressure chamber into the mold cavity. The rationality of its design directly affects the filling speed of the molten metal, pressure transmission, exhaust effect, and the final quality of the casting. The design of the gating system needs to be targeted according to the structural characteristics of the casting, the type of alloy, and the parameters of the die-casting machine to ensure that the molten metal forms an ideal flow state in the mold cavity and reduce the occurrence of defects such as air entrapment, oxidation, and cold shuts. For example, for thin-walled complex castings, the gating system is required to provide a high filling speed so that the molten metal fills the entire mold cavity before solidification; while for thick-walled castings, the filling speed needs to be appropriately reduced to avoid excessive pores caused by turbulent flow of the molten metal.

The pouring system usually consists of four parts: the sprue sleeve, the diverter cone, the runner, and the inner gate. The designs of each part are interrelated and influence each other, and need to be considered as a whole. The sprue sleeve is a key component connecting the pressure chamber and the mold. The shape and size of its inlet need to match the pressure chamber to ensure that the molten metal can flow in smoothly. The common sprue sleeve inlet is a trumpet-shaped one, which is conducive to the introduction of the molten metal and reduces eddy currents. The diverter cone is located below the sprue sleeve. Its function is to divert the molten metal and guide it to the runner, while preventing the molten metal from directly impacting the bottom of the cavity and reducing wear on the mold. The shape of the diverter cone is usually conical or spherical. The cone angle needs to be determined according to the flow rate and flow velocity of the molten metal, generally 60°-90°, to ensure uniform diversion of the molten metal.

The runner is a channel connecting the sprue sleeve and the ingode. Its design must ensure that the molten metal maintains sufficient pressure and speed during the flow process while reducing heat loss. The cross-section of the runner is mostly trapezoidal or semicircular. The runner with a trapezoidal cross-section has the characteristics of low flow resistance and slow heat dissipation, which is suitable for most die castings; the semicircular cross-section is easy to process and is suitable for small and simple castings. The size of the runner needs to be calculated based on the volume of the casting and the filling time. Its length should be shortened as much as possible to reduce the flow of the molten metal and heat loss. Usually, the length of the runner does not exceed 1.5 times the maximum size of the casting. In addition, the runner should be designed to gradually narrow from the sprue sleeve to the ingode, that is, it should have a certain taper (1°-3°) so that the speed of the molten metal gradually increases during the flow process, improving the filling efficiency.

The ingate is the final passage for molten metal to enter the mold cavity. Its design has the most direct impact on casting quality. The location, shape, size, and number of ingates must be precisely designed based on the casting’s structure. The ingate’s position should ensure uniform filling of the mold cavity by the molten metal, avoiding eddies and air entrainment. For symmetrical castings, the ingate should be located at the center of the cavity. For complex castings, multiple ingates can be used to ensure simultaneous filling of all parts. Common ingate shapes include rectangular, trapezoidal, and circular. Rectangular ingates offer high flow rates and fast filling speeds, making them suitable for thin-walled castings. Trapezoidal ingates facilitate smooth metal flow and are suitable for medium-thickness castings. The ingate’s dimensions must be calculated based on the filling speed and molten metal flow rate. Its width and thickness should match the casting’s wall thickness. Typically, the ingate’s thickness is 0.6-0.8 times the wall thickness to ensure optimal flow and filling.

The gating system design must also coordinate with the exhaust and cooling systems. Overflow and exhaust troughs should be installed at the final filling point of the molten metal to drain gas and cold material, preventing the formation of pores and inclusions within the casting. Furthermore, the gating system should be arranged to avoid interference with cooling channels to ensure uniform temperature across the mold. After the design is completed, the molten metal filling process is simulated and analyzed using computer simulation software to observe the flow trajectory, pressure distribution, and temperature changes of the molten metal, predicting potential defects and optimizing them. For example, when designing the gating system for a die-casting mold for an automotive engine block, a company discovered through simulation that the original design’s ingate placement resulted in uneven metal filling, posing a risk of cold shut. After adjusting the number and placement of the ingates, the metal filling became more uniform, and the casting pass rate increased from 75% to 92%. Therefore, gating system design requires continuous optimization and refinement. Only through comprehensive consideration and scientific verification can an efficient and stable gating system be designed.