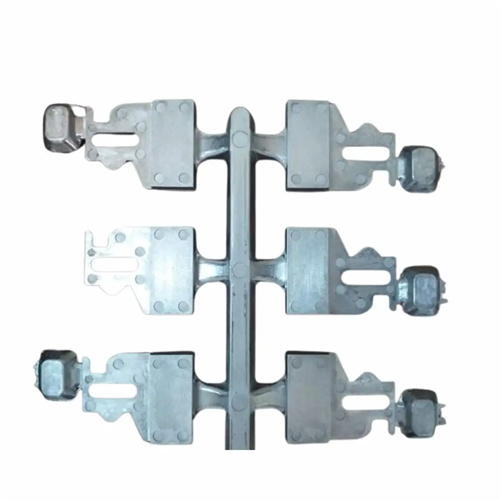

Structural composition of die casting mold

The structure of a die-casting mold is complex, with multiple functional components working together to ensure a smooth die-casting process and consistent casting quality. These components primarily include the cavity assembly, gating system, guide mechanism, ejector mechanism, cooling system, and mold base. The cavity assembly, the core of the mold, consists of a fixed die core and a movable die core. The cavity they form defines the shape of the casting. The fixed die core is fixed to the fixed die base plate, while the movable die core is mounted on the movable die base plate. When the mold is closed, the two tightly fit together to form a closed cavity. The cavity assembly must be made of materials that are resistant to high temperatures, high strength, and wear. It is typically made of hot-working die steels such as H13 and 3Cr2W8V, which are forged, heat-treated, and precision-machined. Surface roughness must be kept to a minimum to ensure the casting’s surface quality. For example, in die-casting molds for aluminum alloy wheels, the cavity surface must be polished to a roughness of Ra0.4μm to ensure a smooth and flawless wheel surface.

The gating system is the channel connecting the pressure chamber to the mold cavity, responsible for introducing the molten metal into the cavity. It consists of a sprue sleeve, diverter cone, runner, and ingates. The sprue sleeve docks with the pressure chamber to guide the molten metal into the mold. Its entrance is usually designed in a bell-shaped shape to facilitate smooth inflow of the molten metal. The diverter cone, located below the sprue sleeve, diverts the molten metal and directs it toward the runner, while preventing it from directly impacting the mold cavity and reducing mold wear. The runner is the channel connecting the sprue sleeve to the ingates, typically designed with a trapezoidal or U-shaped cross-section to maintain a certain speed and pressure during the flow of the molten metal. The ingates are the final passage for the molten metal to enter the mold cavity. Their size and shape are determined by the casting structure and directly affect the filling speed and flow state of the molten metal. For example, the ingates of thin-walled castings have a smaller cross-sectional area to ensure a higher filling speed.

The guide mechanism is used to ensure the precise positioning of the mold during the mold closing and opening processes and to prevent misalignment of the cavity components. It is mainly composed of guide pins, guide sleeves, and locating pins. The guide pins are installed on one side of the movable or fixed mold, and the guide sleeves are installed on the other side. The guide pins and guide sleeves use a clearance fit with a fit accuracy of H7/h6 to ensure that the guide pins can be smoothly inserted into the guide sleeves during mold closing for precise guiding. Large die-casting molds usually have 4-6 sets of guide pins and sleeves distributed at the four corners of the mold, while small molds can have 2-4 sets. Locating pins are used to assist in positioning and are installed around the cavity to further improve the mold closing accuracy and prevent the wear of the guide pins caused by long-term use from affecting the positioning accuracy. Lubrication of the guide mechanism is also very important. Usually, an oil groove is set on the guide sleeve, and high-temperature grease is regularly added to reduce wear and extend the service life.

The ejector mechanism, which ejects the casting from the cavity after mold opening, consists of ejector pins, ejector rods, ejector plates, ejector plates, and a reset rod. Ejector pins are the components that come into direct contact with the casting and are evenly distributed according to the structure and shape of the casting. The diameter and length of the ejector pins are determined based on the ejection force to avoid bending due to overly thin ejector pins or uneven ejection that could cause deformation of the casting. For large or complex castings, ejector plates and ejector tubes can also be used to ensure smooth ejection. The ejector mechanism is driven by the die-casting machine’s ejector cylinder, which uses the ejector rod to move the ejector plate and ejector pins to complete the ejection process. The reset rod pushes the ejector mechanism back into position during mold closing, ensuring accurate closing the next time. The ejector mechanism must be designed to avoid interference with the mold cavity, cooling channels, and other components. A reasonable clearance between the ejector pins and the mold—typically 0.01-0.02mm—is required to prevent molten metal leakage.

The cooling system and mold base are essential components of the die-casting mold. The cooling system consists of cooling water channels, seals, and water pipe joints, distributed within the fixed and movable molds. Circulating cooling water removes heat absorbed by the mold, maintaining a reasonable temperature range. The layout of the cooling water channels should be determined by the cavity shape, keeping them as close to the cavity surface as possible. The inlet and outlet temperature differential should be kept to a minimum, generally within a range of 5-10°C. Seals prevent cooling water leakage and are typically made of high-temperature-resistant nitrile rubber or fluororubber. Water pipe joints connect the mold to the external cooling system, facilitating installation and removal. The mold base, comprising the fixed and movable mold bases, movable mold pads, and support plates, serves to secure and support various functional components, ensuring overall mold rigidity and strength. The mold base is typically made of 45 steel or Q235 steel, and is machined to achieve sufficient flatness and verticality to ensure accurate alignment of the mold when installed on the die-casting machine. For example, the mold frame thickness of a large die-casting mold can reach 200-300mm to withstand the huge clamping force when closing the mold and prevent deformation.