Types of die casting parting surfaces

There are many different types of parting surfaces, each suitable for castings with different structures. Understanding the types and characteristics of parting surfaces helps select the appropriate one during mold design, improving casting quality and production efficiency. Parting surfaces can be categorized into various types based on their shape and location, including flat, inclined, stepped, curved, and combined. Each type has its own unique application scenarios and design considerations.

A flat parting surface is the most common and simplest type of parting surface. It is flat and suitable for castings with simple shapes and smooth contours, such as flat plate and disc die castings. The advantage of a flat parting surface is that it is easy to process. Simple processing techniques such as milling and grinding can achieve high flatness and surface roughness. It also has good sealing when the mold is closed, and can effectively reduce the generation of flash. For example, when producing thin-walled flat castings such as mobile phone casings, a flat parting surface is used. This not only reduces mold processing costs, but also makes it easy to ensure the dimensional accuracy of the casting. In addition, a flat parting surface facilitates the arrangement of exhaust grooves. Continuous exhaust grooves can be opened at the edge of the parting surface to ensure smooth exhaust.

The bevel parting surface is shaped like an inclined plane and is suitable for castings with inclined structures or inclined surfaces, such as wedge-shaped and conical parts. The inclination angle of the bevel parting surface should match the inclination angle of the casting to ensure smooth demolding of the casting. Its advantage is that it can adapt to the inclined structure of the casting, avoid leaving obvious parting marks on the casting surface, and improve the surface quality of the casting. For example, for a die-casting with a 15° inclined surface, using a 15° bevel parting surface can form the inclined surface of the casting in one go, without the need for subsequent machining. However, the machining of bevel parting surfaces is relatively difficult, requiring precise control of the inclination angle. The guiding accuracy requirements during mold closing are also high, and it is usually necessary to use guide mechanisms such as guide pins and guide sleeves to ensure accurate mold closing.

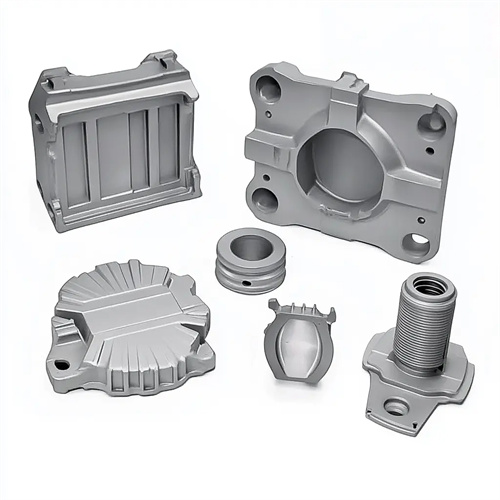

The stepped parting surface is composed of multiple planes of different heights and is suitable for castings with complex shapes, multiple steps or concave-convex structures, such as box-type and shell-type die-castings. The stepped parting surface can match the mold cavity with the step structure of the casting, ensuring that each step part can be reasonably parted, avoiding flash or deformation of the casting due to unreasonable parting surface. For example, for a casting with three steps of different heights, a stepped parting surface is used, with each step corresponding to a parting plane, so that the fixed mold and the movable mold can fit accurately, ensuring the dimensional accuracy of each step of the casting. The disadvantage of the stepped parting surface is that the processing is complicated, requiring multiple clamping and processing, and the mold manufacturing cost is relatively high. At the same time, the sealing requirements during mold closing are also high, and it is necessary to ensure that each step surface can fit tightly.

The shape of the curved parting surface is a curved surface, which is suitable for castings with curved contours, such as automobile covers, special-shaped curved parts, etc. The curved parting surface can completely fit the curved contour of the casting, ensuring that the curved shape of the casting is formed in one go, with good surface quality and no need for subsequent processing. For example, when producing curved castings such as automobile fenders, using a curved parting surface that is consistent with the fender curve can ensure that the surface accuracy of the casting meets the design requirements and the surface is smooth and flawless. However, the processing of curved parting surfaces is the most difficult, requiring the use of CNC machining centers for precision processing, and even requiring electrical discharge machining and polishing to ensure the accuracy and surface roughness of the curved surface. In addition, the mold closing guide requirements of the curved parting surface are also very high, and usually a dedicated guide mechanism is required to ensure that the curved surface can fit accurately when the mold is closed.

Combined parting surfaces are made up of two or more different types of parting surfaces and are suitable for castings with extremely complex structures, such as comprehensive castings with multiple structures such as planes, slopes, and curves. Combined parting surfaces can fully utilize the advantages of various parting surfaces, adapt to the structural characteristics of different parts of the casting, and ensure that the casting can be smoothly demolded and of qualified quality. For example, for a complex shell casting with both planes, slopes, and curved surfaces, a combination of plane parting surfaces, slope parting surfaces, and curved parting surfaces is used. The plane part uses a plane parting surface, the slope part uses a slope parting surface, and the curved part uses a curved parting surface, so that the mold can meet the parting requirements of each part of the casting. The design and processing of combined parting surfaces is the most complex, requiring a detailed analysis of the structure of the casting and a reasonable division of the range and connection method of each parting surface. At the same time, the processing and assembly accuracy requirements of the mold are also extremely high.