Commonly used die-casting alloys and their main properties

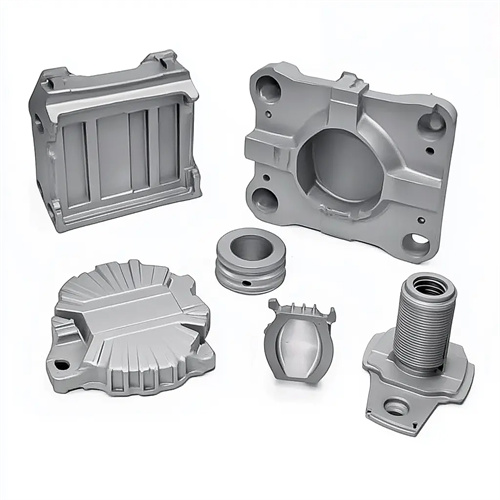

Common die-casting alloys are widely used metal materials in die-casting production. Their properties directly determine the application scenarios and quality performance of the castings. Aluminum alloy is currently one of the most widely used die-casting alloys. Its low density (approximately 2.7g/cm³), high specific strength, and excellent corrosion resistance have made it a key player in the automotive, electronics, aerospace, and other fields. Commonly used die-cast aluminum alloys include Al-Si, Al-Si-Cu and Al-Si-Mg. Among them, Al-Si alloys (such as YL113) have excellent fluidity and casting properties, and are suitable for the production of complex thin-walled castings. Their tensile strength can reach 200-300MPa and their elongation is 5%-8%. Al-Si-Cu alloys (such as YL112) have improved strength and hardness due to the addition of copper elements, and their tensile strength can reach 250-350MPa, but their corrosion resistance is slightly reduced. They are suitable for structural parts that bear certain loads. Al-Si-Mg alloys (such as ADC12) have both good strength and corrosion resistance. After aging treatment, their tensile strength can be increased to more than 300MPa. They are often used in important components such as automobile engine blocks and gearbox housings.

Zinc alloy is another commonly used die-casting alloy. Its low melting point (approximately 420°C), good fluidity, and excellent casting properties make it suitable for the production of small precision castings, such as electronic connectors, toy accessories, and bathroom hardware. Common die-cast zinc alloys include the Zn-Al-Cu series (such as Zamak3 and Zamak5). Zamak3 alloy contains 3.5%-4.3% aluminum and less than 0.03% copper, offering excellent fluidity and machinability, a tensile strength of approximately 280 MPa, and an elongation of 10%, making it suitable for the production of castings requiring high aesthetics. Zamak5 alloy, with its copper content increased to 0.7%-1.2%, exhibits increased strength and hardness, reaching a tensile strength of 320 MPa and an elongation of 7%, making it suitable for parts subject to moderate loads. However, zinc alloys have the disadvantage of poor corrosion resistance and are prone to intergranular corrosion with long-term use. Therefore, they are primarily used in indoor environments or for parts that require surface treatment.

Magnesium alloy, a lightweight die-cast alloy with a density of only approximately 1.8g/cm³, is currently the lightest metal structural material in practical use. It features high specific strength, excellent shock absorption, and thermal conductivity, and is increasingly used in automotive, consumer electronics, and other fields. Commonly used die-cast magnesium alloys are the Mg-Al-Zn series (such as AZ91D), which contains 8.3%-9.7% aluminum and 0.3%-1.0% zinc. They have a tensile strength of approximately 230 MPa and an elongation of 3%. These alloys exhibit excellent casting and mechanical properties, making them suitable for parts such as automotive steering wheels and laptop casings. However, magnesium alloys have the disadvantage of being easily oxidized, requiring the die-casting process to be conducted in a protective gas atmosphere (such as a mixture of SF6 and nitrogen) to prevent combustion of the molten metal. Furthermore, magnesium alloys have poor corrosion resistance, requiring surface treatments (such as anodizing and spraying) to enhance their corrosion resistance.

Copper alloy die-casting, due to its high melting point (pure copper melts at 1083 °C) and excellent thermal and electrical conductivity, is suitable for the production of parts requiring high thermal and electrical conductivity, such as radiators, motor end caps, and valves. Commonly used copper alloys for die-casting are brass ( Cu-Zn alloy) and bronze ( Cu-Sn alloy). Brass (such as HPb59-1 ) contains 57%-60% copper and 1%-2% lead , offering excellent fluidity and machinability, a tensile strength of approximately 400 MPa , and a thermal conductivity of 100-120 W/(m · K) , making it suitable for the production of heat-dissipating components such as radiators. Bronze (such as tin bronze) offers greater wear and corrosion resistance, making it suitable for wear-resistant parts such as bearings and gears. However, its casting properties are relatively poor, making die-casting more difficult. The disadvantages of copper alloy die-casting are high energy consumption and short mold life, limiting its application range.

The performance differences between commonly used die-casting alloys determine their applicable scenarios. In actual production, appropriate selection must be made based on the intended use of the casting. For example, automotive body structural parts require both lightweight and strength, so aluminum or magnesium alloys are often used. Heat dissipation components in electronic equipment require high thermal conductivity, so copper alloys may be used. Zinc alloys are preferred for small precision parts. The alloy’s processability must also be considered. For example, aluminum and zinc alloys offer excellent casting properties, making them suitable for mass production. However, magnesium and copper alloys have more demanding die-casting processes, requiring specialized equipment and process measures. An automotive parts company, after comparing the performance of aluminum and magnesium alloys for the production of motor housings for new energy vehicles, ultimately selected AZ91D magnesium alloy. This reduced the weight of the part by 30%, while meeting strength and heat dissipation requirements and improving the vehicle’s range.