Analysis of Typical Die Casting Gating System

In the production process of die-casting parts, the pouring system plays a key role in connecting the pressure chamber and the cavity. The rationality of its design directly affects the quality of the die-casting parts, production efficiency and mold life. A typical die-casting pouring system usually consists of a sprue, a runner, an inner runner and a gate sleeve. The structure and size of each component must be precisely matched according to the shape, size, material and production process parameters of the die-casting part. The sprue is the first channel for the molten metal to enter the cavity from the pressure chamber. Its length and diameter must take into account the flow rate and pressure loss of the molten metal. Generally speaking, the diameter of the sprue should be slightly smaller than the diameter of the pressure chamber to avoid eddies or turbulence in the molten metal during the flow process, ensuring that the molten metal smoothly fills the cavity.

The main function of the runner is to distribute the molten metal delivered by the sprue to the various ingrowns, while also acting as a slag barrier and stabilizing the flow of the molten metal. When designing the runner, it is necessary to ensure that its cross-sectional area gradually decreases from the sprue to the ingrown, forming a certain pressure gradient, which promotes the rapid and uniform entry of the molten metal into the mold cavity. In addition, the runner should avoid sharp turns as much as possible to prevent the molten metal from generating eddies at corners, entraining gas or slag, and thus affecting the internal quality of the die-casting. For die-castings with complex shapes, a multi-branch runner design can be adopted to ensure that the molten metal filling speed of each ingrown is consistent.

As the final passage for molten metal to enter the mold cavity, the location, number, and shape of the ingrowth are crucial to the molding quality of the die-casting. The ingrowth should be located as close to the thickest part of the die-casting as possible to facilitate shrinkage compensation of the molten metal and reduce the occurrence of defects such as shrinkage cavities and porosity. At the same time, the ingrowth should not be directly facing the mold cavity wall or core to prevent the molten metal from directly impacting the mold cavity, causing local overheating or core deformation. The number of ingrowths should be determined based on the size and complexity of the die-casting. For large or complex die-castings, multiple ingrowths can be installed to achieve uniform filling of the molten metal. However, attention should be paid to the balanced flow distribution of each ingrowth to avoid local underfilling or overfilling.

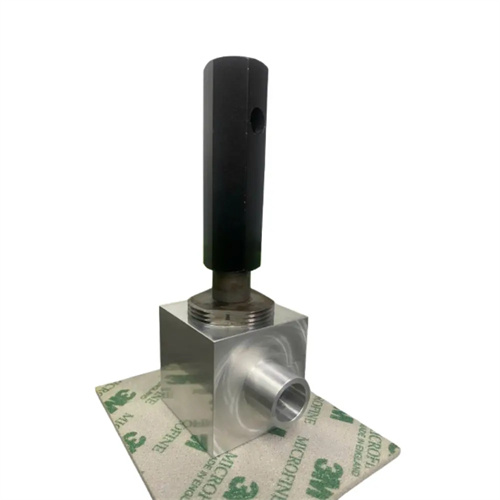

As a key component connecting the pouring system to the pressure chamber, the sprue sleeve’s structural design must ensure smooth passage of molten metal from the pressure chamber into the sprue while preventing leakage. The sprue sleeve’s inlet is typically rounded to reduce flow resistance. Its length should be determined based on the mold thickness and the position of the pressure chamber, generally ensuring sufficient pressure and velocity before the molten metal enters the sprue. Furthermore, the sprue sleeve’s material must possess high heat and wear resistance to withstand the high temperatures and repeated impacts of the molten metal, thereby extending its service life.

In actual production, the design of the gating system requires simulation and optimization based on the specific characteristics of the die-casting. Computer simulation software can analyze the flow state, temperature distribution, and pressure changes of the molten metal in the gating system, predicting potential defects and implementing corrective measures in advance. For example, for thin-walled die-castings, the cross-sectional area of the ingates needs to be appropriately increased to increase the filling speed of the molten metal and prevent cold shut defects. For die-castings with thicker and more extensive sections, the location and number of ingates need to be optimized to ensure sufficient shrinkage of the molten metal and reduce the occurrence of internal pores and shrinkage cavities. Only by continuously optimizing the gating system design can high-quality and efficient production of die-castings be achieved.