Die casting heating and cooling system design

The die-casting heating and cooling system is the “temperature control center” that regulates the mold temperature. Its function is to heat the mold to its optimal operating temperature and promptly remove excess heat during the die-casting process, maintaining a uniform and stable mold temperature field. This ensures smooth molten metal filling, uniform solidification of the die-cast part, and minimizes defects such as shrinkage and deformation. The system’s design must be precisely matched to the alloy type, die-cast part structure, and production cycle. For low-temperature alloys (such as zinc alloys, with pouring temperatures of 400-450°C), cooling is the primary method, while for high-temperature alloys (such as copper alloys, with pouring temperatures of 900-1100°C), a combination of heating and cooling is required. A well-designed temperature control system can increase the die-casting qualification rate by 15%-20% and extend the mold life by over 30%.

The mold heating system must be designed to meet the requirements of rapid temperature rise and uniformity, especially for die-casting of high-melting-point alloys or large, complex molds. Common heating methods include electric heating tubes and hot oil circulation. Electric heating tubes offer a simple structure and rapid temperature rise, making them suitable for small and medium-sized molds. The power of the heating tubes is calculated based on the mold mass, generally 50-100W/kg. They are installed in the heating holes of the mold sleeve, with a hole depth of 0.8-0.9 times the length of the heating tube. The gaps between the heating tubes and the heating tubes should be filled with thermal grease to improve heat transfer efficiency. The heating tubes should be evenly spaced, with spacing of 200-300mm. In areas with complex cavities or thicker walls, they should be spaced closer together to ensure a temperature difference of ≤10°C across all parts of the mold. For large molds (weighing over 10 tons), hot oil circulation is recommended. An oil pump delivers thermal oil at 150-200°C into the heating channels within the mold. The oil flow rate is calculated based on the heat load, generally 5-10L/min. This method provides better temperature uniformity and can control temperature differences within 5°C.

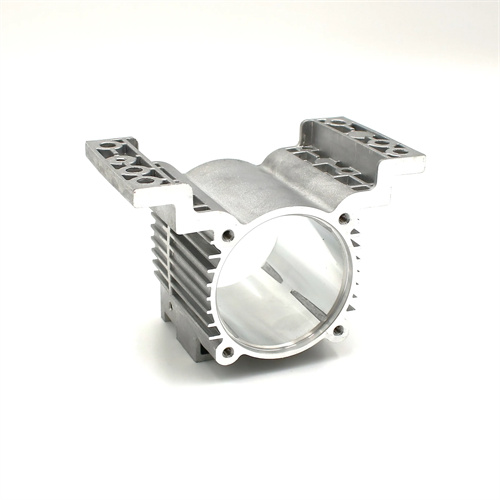

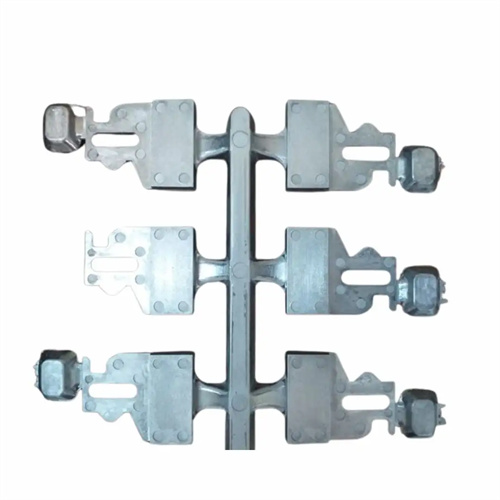

The core of the cooling system is to remove heat absorbed by the mold through the flow of coolant. Its design should adhere to the principle of “local cooling and uniform heat dissipation.” The layout of the cooling channels must adapt to the cavity shape, forming a “cooling ring” around the cavity. The distance between the center of the channel and the cavity surface is typically 15-25 mm. A smaller distance can lead to localized overcooling, while a larger distance can result in insufficient cooling efficiency. The channel diameter should be 8-16 mm depending on the mold size, with a maximum of 8-10 mm for small molds and 12-16 mm for large molds. Ensure a coolant flow rate of 1.5-3 m/s to create turbulent flow and enhance heat transfer. For thin-walled die castings (wall thickness < 3 mm), dense channels with a spacing of 50-80 mm are required. For thick-walled areas (wall thickness > 10 mm), conformal channels or jet cooling can be used. This involves installing cooling nozzles inside the core to directly spray coolant at heat-concentrated areas, which can increase cooling speed by 30%-50%. The inlet and outlet of the water channel must be set on the non-working surface of the mold and connected with quick connectors to facilitate mold installation and maintenance.

The parameter setting and adjustment mechanism of the temperature control system are key to ensuring temperature stability. The mold operating temperature must be determined according to the type of alloy: zinc alloy molds are controlled at 150-200°C, aluminum alloy molds at 200-250°C, and copper alloy molds at 250-350°C. Thermocouples (accuracy ±1°C) installed in the mold cavity and core monitor the temperature in real time. When the actual temperature deviates from the set value, the thermostat automatically adjusts the heating power or coolant flow. For complex molds, a zoned temperature control strategy can be adopted, dividing the mold into multiple independent temperature control units such as the gate area, cavity area, and core pulling area. Each unit is equipped with a separate sensor and actuator. For example, the gate area temperature must be 10-20°C higher than the cavity area to prevent premature solidification of the molten metal. In the early stages of die-casting production, the mold temperature must be preheated to the set value. The preheating time is calculated based on the mold quality and is generally 0.5-2 hours to avoid die-casting defects caused by cold mold startup.

The auxiliary design of the heating and cooling system must balance safety and cost-effectiveness. To prevent coolant leakage, O-rings should be used at the water channel joints. The material should be oil-resistant and high-temperature resistant fluororubber. The operating temperature range is -20°C to 200°C, and the compression ratio should be controlled at 20% to 30%. The interior of the water channel should be treated with rust-proof treatment, such as galvanizing or chrome plating, to prevent rust from clogging the channel. The water channel should be cleared every 10,000 molds to ensure smooth flow. For electric heating systems, an overheating protection device should be installed. When the temperature exceeds the set point of 50°C, the power will be automatically cut off to prevent mold damage from overheating. In addition, the system should consider energy-saving design, such as wrapping the mold surface with insulation material to reduce heat loss. The insulation layer should be 5-10mm thick and made of aluminum silicate fiber with a thermal conductivity of ≤0.1 W/(m · K) . By recycling waste heat from the cooling system for mold preheating, energy consumption can be reduced by 10% to 15% , achieving green production.

System verification and optimization are necessary steps to ensure the temperature control effect. After the mold is manufactured, the temperature field distribution of the mold needs to be detected by a thermal imager to check whether there are local overheating or overcooling areas. For areas where the temperature difference exceeds 15°C, it is necessary to add cooling water channels or adjust the position of the heating elements. Through mold trials, the temperature change curve under different process parameters is tested to establish a corresponding relationship between temperature and die-casting quality. For example, when the temperature of the aluminum alloy mold is lower than 180°C, the die-casting is prone to cold shut defects; when it is higher than 280°C, the surface is prone to mold sticking. According to the mold trial results, the water channel diameter, flow rate, heating power and other parameters are iteratively optimized to ultimately control the mold temperature fluctuation within ±5°C. For molds produced in batches, the accuracy of the temperature control system needs to be checked regularly, and the thermocouples and temperature controllers need to be calibrated at least once a year to ensure the accuracy and reliability of temperature control and provide continuous protection for the stable quality of die-castings.