Die Casting Principle

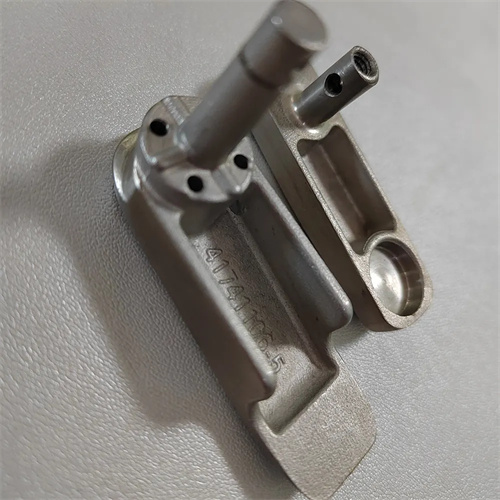

As an efficient and precise metal forming process, die casting’s core principle is to use high pressure to force molten metal into the mold cavity at high speed. After rapid cooling and solidification, a die-casting part with the same shape as the cavity is obtained. This process combines metal smelting, high-pressure filling, and rapid solidification. It has the characteristics of high production efficiency, high dimensional accuracy, and good surface quality. It is widely used in the automotive, home appliance, 3C and other fields.

High-pressure, high-speed filling of molten metal is a core element of die casting. A die-casting machine uses an injection cylinder to force molten metal from a pressure chamber into the gating system. The injection force is typically 5-150 MPa, resulting in a filling speed of 5-50 m/s. This high pressure and high speed ensures that the molten metal fills complex cavities before solidification, especially thin-walled areas (with a minimum wall thickness of 0.5 mm). The filling process is divided into a slow phase (0.1-1 m/s) and a fast phase (5-50 m/s). The slow phase steadily pushes the molten metal into the ingrown gate to avoid air entrainment, while the fast phase ensures a continuous flow of molten metal in the cavity to prevent cold shuts. For example, die-casting a mobile phone midframe requires a high-speed filling speed of 15-25 m/s to ensure a complete formation of thin walls as thin as 0.8 mm. Large automotive castings, such as transmission housings, require a lower speed (5-10 m/s) combined with high pressure (80-120 MPa) to balance filling and feeding.

The rapid cooling and solidification of the mold cavity determines the quality of die-castings. Molds are typically made of hot-working die steels such as H13 steel and feature internal cooling channels. Circulating water removes heat, allowing the molten metal to solidify within 1 to 10 seconds. The cooling rate significantly affects the microstructure of die-cast parts. Rapid cooling (cooling rates > 100°C/s) refines the grain size and improves the strength and hardness of die-cast parts. For example, the tensile strength of aluminum alloy die-castings can be increased by 15% to 20% after rapid cooling. During solidification, the die-casting machine continuously applies pressure (typically 50% to 80% of the injection force) through a holding pressure system, pushing unsolidified molten metal to fill the shrinkage space in the mold cavity and reduce defects such as shrinkage cavities and porosity. The holding time must match the solidification time. Thin-walled parts require 0.5 to 2 seconds, while thick-walled parts require 3 to 10 seconds to ensure the density of the die-cast parts. By optimizing the holding parameters, the density of the die-casting of an engine cylinder block has been increased from 95% to 99%.

The die-casting machine’s operating cycle, coordinated with the mold, is fundamental to the successful process. A typical die-casting cycle includes: mold closing (closing the movable and fixed molds with a clamping force of 500-5000 kN) → pouring (injecting molten metal into the pressure chamber) → injection (pushing the molten metal into the mold cavity with high pressure) → holding pressure (feeding to prevent shrinkage defects) → cooling (solidification and formation of the molten metal) → mold opening (separating the movable and fixed molds) → ejection (ejecting the die-casting part from the mold cavity). A single cycle completes in just 10-60 seconds, significantly less than the several hours required for sand casting, making it suitable for mass production. During this cycle, the mold must provide precise guidance (closing accuracy ≤ 0.03mm), reliable core pulling (accommodating complex structures like side holes), and effective venting (eliminating over 90% of the gas in the mold cavity). This cycle is precisely synchronized with the die-casting machine’s movements. For example, core pulling must be completed 0.5-1 second before mold opening to prevent core damage to the die-casting part.

The differences in die-casting characteristics between different alloys stem from their material properties. Zinc alloy (melting point 380-420°C) is suitable for die-casting thin-walled, complex parts due to its low melting point and good fluidity. Fill speeds can be as low as 3-5 m/s, and mold life can reach 100,000-300,000 cycles. Aluminum alloy (melting point 580-680°C) is a primary material for automotive die-casting due to its high strength and lightweight, but requires higher fill speeds (10-30 m/s) and mold temperatures (200-250°C) to prevent cold shuts. Copper alloy (melting point 900-1100°C) has good thermal conductivity, but its high melting point and poor fluidity require higher injection pressures (80-150 MPa) and mold temperatures (300-400°C) during die-casting, resulting in a shorter mold life (typically less than 50,000 cycles). According to the characteristics of different alloys, the corresponding die-casting machine tonnage and mold design need to be matched. For example, zinc alloy die-casting uses a 100-500 ton die-casting machine, while copper alloy requires an 800-2000 ton large die-casting machine.

The development trend of die-casting technology is characterized by precision and intelligence. With the increasing precision requirements for die-cast parts (dimensional tolerances reaching IT6-IT8), advanced technologies such as vacuum die-casting (cavity vacuum <50 mbar) and oxygen-filled die-casting have emerged. These technologies reduce gas defects, enable die-cast parts to undergo T6 heat treatment (for aluminum alloys), and increase strength by over 30%. In terms of intelligence, by integrating temperature and pressure sensors into the mold and combining them with AI algorithms to adjust injection parameters in real time, one intelligent die-casting production line has increased the die-casting qualification rate from 92% to 98%. Furthermore, large-scale integrated die-casting (such as Tesla's 4680 battery case) utilizes ultra-large molds (weighing > 50 tons) and 6,000-9,000-ton die-casting machines to integrate multiple parts and reduce welding steps, demonstrating the enormous potential of die-casting technology in terms of efficiency and cost control.