Selection of die-casting alloys

The selection of die-casting alloys is a critical decision that impacts the quality, cost, and service life of die-cast parts. The optimal solution must be determined through a multi-dimensional evaluation, taking into account the product structure, operating environment, performance requirements, and production economics. The selection process should avoid blindly pursuing high performance or low price, but rather seek the optimal balance between performance and cost to ensure that die-cast parts meet service requirements while achieving efficient and low-cost production.

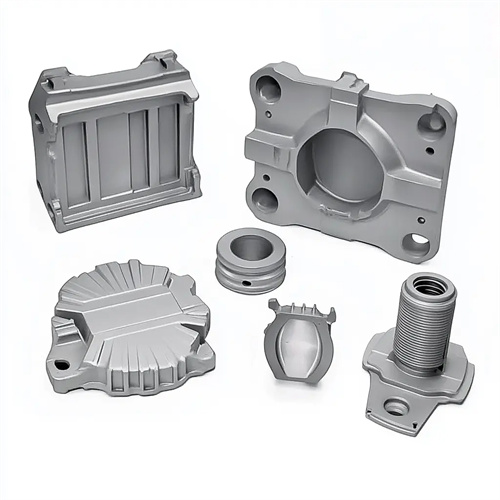

Product structure and molding difficulty are the primary considerations when selecting alloys, directly impacting the feasibility and stability of the die-casting process. For thin-walled, complex parts (wall thickness ≤ 2mm, with multiple side holes or deep cavities), alloys with excellent fluidity are preferred, such as the zinc alloy Zamak3 or aluminum alloy ADC12. These alloys have spiral lengths ≥ 900mm and ≥ 650mm, respectively, enabling high-speed filling of complex cavities, reducing defects such as cold shuts and under-casting. For large, thick-walled parts (wall thickness ≥ 10mm, dimensions exceeding 1m), both fluidity and shrinkage-feeding capacity must be considered. Aluminum alloy A380, with its 10%-13% silicon content and 3%-4% copper content, offers excellent fluidity and uniform solidification shrinkage, making it an ideal choice. For lightweighting requirements, magnesium alloy AZ91D can be used, but the mold temperature must be appropriately increased (200-220°C) to improve filling. For parts with core-pulling structures, the demoulding properties of the alloy need to be considered. Zinc alloy has better demoulding properties than aluminum and magnesium alloys, which can reduce the amount of release agent and mold wear. It is suitable for precision parts with multiple core-pulling structures, such as watch movements.

The physical and chemical properties of the operating environment determine the alloy’s weather resistance requirements, necessitating the selection of alloys with specific corrosion resistance, high-temperature resistance, or low-temperature resistance. In humid or corrosive environments (such as marine and chemical industries), alloys with excellent corrosion resistance, such as aluminum-magnesium alloys (5-series) or surface-treated magnesium alloys, should be selected. 5-series aluminum alloys offer salt spray resistance 3-5 times that of standard aluminum alloys, making them suitable for marine components. Copper alloys can be used if cost permits, but copper’s high electrical potential should be avoided, preventing galvanic corrosion from contact with other metals. In high-temperature environments (such as engine compartments and boiler components), heat-resistant alloys are essential. Aluminum alloy 2014, containing 4-5% copper, maintains a tensile strength retention of ≥80% at 250°C. The copper alloy ZCuSn10Pb1 can operate at temperatures exceeding 300°C for extended periods, making it a preferred choice for high-temperature components. In low-temperature environments (such as refrigeration equipment), the low-temperature toughness of the alloy must be ensured. The impact toughness of the magnesium alloy AM60B can still maintain more than 80% of the room temperature value at -40°C, which is better than aluminum alloys and zinc alloys.

Mechanical performance requirements must be aligned with the stress conditions of the component to avoid excessive or insufficient performance. For structural components subject to static loads (such as brackets and housings), medium-strength alloys such as aluminum alloy ADC12 (tensile strength 220-260 MPa) or zinc alloy Zamak3 (180-220 MPa) can meet these requirements and offer a high cost-effectiveness. For components subject to dynamic loads or impact (such as automotive suspensions and airbag brackets), high-strength and high-toughness alloys are essential. Aluminum alloy 6061, after T6 treatment, achieves a tensile strength of 310 MPa and an elongation of 12%. Magnesium alloy AZ80 offers a tensile strength of 290 MPa and an elongation of 7%, while also offering significant lightweighting advantages. For parts requiring high hardness and wear resistance (such as gears and guide rails), aluminum alloys with high silicon content (such as A390, 16%~18% silicon) can be selected. Its primary silicon particles can improve wear resistance and achieve a hardness of 110~130HBW; or zinc alloy Zamak5 can be selected, which can achieve a hardness of 100~110HBW through surface quenching.

Production economics are essential considerations for large-scale production, requiring a comprehensive assessment of material cost, molding efficiency, and post-processing costs. Zinc alloys have a lower material cost (approximately 20 yuan/kg) than aluminum (25-30 yuan/kg) and magnesium (40-50 yuan/kg), and offer a short die-casting cycle (10-20 seconds/die), making them suitable for high-volume, low-cost parts such as toys and small hardware. Aluminum alloys offer a moderate overall cost, high molding efficiency (20-40 seconds/die), and a recycling rate exceeding 95%, making them suitable for medium-to-large-scale production in applications such as automobiles and home appliances. Magnesium alloys have a higher material cost, but the energy savings from lightweighting can partially offset this cost, making them suitable for high-end applications such as aerospace and new energy vehicles. Copper alloys have the highest cost (60-80 yuan/kg) and a shorter die life (only 1/5-1/10 that of aluminum alloys), limiting their use to small batches of parts with specialized performance requirements. Post-processing costs also need to be considered. The surface treatment cost of magnesium alloy is 2 to 3 times that of aluminum alloy, while zinc alloy does not require complicated treatment and can be directly electroplated.

Specialized alloys are required for special functional requirements (such as electrical conductivity, thermal conductivity, and shielding) to meet the product’s functional specifications. Conductive parts (such as electrical contacts and connectors) require high-conductivity alloys. Brass ZCuZn38Pb2 has a conductivity of 25% IACS (International Annealed Copper Standard), making it suitable for low-current applications. For higher conductivity requirements (≥ 40% IACS ), copper alloys with a copper content of 90% or more are required, but die-casting increases the difficulty. Thermally conductive parts (such as heat sinks) require high-thermal conductivity alloys. Copper alloy ZCuSn10Pb1 has a thermal conductivity of 55W/(m・K) , twice that of aluminum alloy , making it suitable for cooling high-power devices. Aluminum alloy 6063 has a thermal conductivity of 160W/(m・K) , offering a more cost-effective solution for general cooling applications. Electromagnetic shielding parts (such as 5G equipment casings) must use alloys with high conductivity and good sealing properties. After conductive oxidation treatment, the shielding effectiveness of magnesium alloy reaches 60~80dB, which is better than plastic sprayed metal and is lighter.