Vacuum die casting

Vacuum die-casting is an advanced process that integrates a vacuum system into traditional die-casting. This process extracts air and volatiles from the mold cavity, reducing gas entrapment during molten metal filling. This process results in low-porosity, high-density die-cast parts. This process is particularly suitable for die-castings requiring high airtightness and mechanical properties, such as automotive engine blocks and hydraulic valve bodies. It effectively addresses the leakage and strength deficiencies associated with porosity in traditional die-casting.

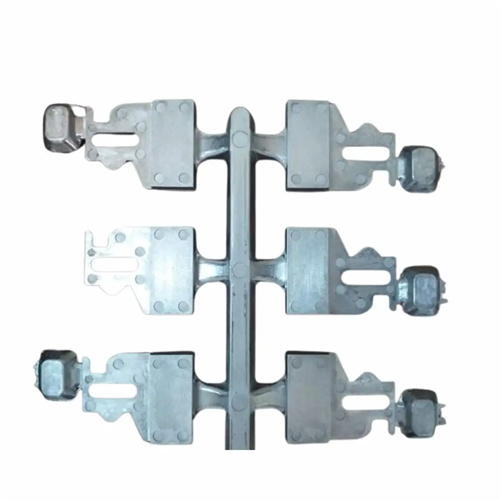

The design and control of the vacuum system are central to vacuum die-casting, directly impacting the vacuum level and quality of die-cast parts. The vacuum system primarily consists of a vacuum pump, vacuum valve, vacuum piping, and pressure sensors. The vacuum pump’s pumping rate is determined by the cavity volume, typically ranging from 50 to 500 L/s, ensuring the cavity vacuum is reduced to below 50 mbar (ideally ≤ 20 mbar) before molten metal is filled. The vacuum valve’s response time must be ≤ 0.05 seconds, enabling precise control of the start and end of the pumping operation. Typically, the pumping operation begins after the punch passes the gate and closes when the molten metal fills 70% to 80% of the cavity to prevent the molten metal from being drawn into the vacuum piping. The vacuum piping’s diameter must be sufficiently large (≥ 20 mm) to minimize pumping resistance, and the piping layout should be as short as possible to ensure uniform vacuum across the cavity (temperature differential ≤ 10 mbar). The pressure sensor’s accuracy must reach ±1 mbar, providing real-time monitoring of the cavity vacuum level and ensuring a stable production process.

Vacuum die-casting process parameters must be optimized in conjunction with the vacuum system to achieve optimal results. Controlling the injection speed is particularly critical. During the low-speed phase (0.1-1 m/s), the molten metal must be advanced slowly to prevent premature closure of the exhaust channel. During the high-speed phase (3-15 m/s), rapid filling is required under vacuum, utilizing vacuum-assisted exhaust. This speed is 20%-30% lower than that of traditional die-casting at high speeds to prevent secondary air entrainment caused by metal splashing. The injection pressure must be increased by 10%-20% compared to traditional die-casting to compensate for the slight decrease in molten metal fluidity in vacuum and ensure full cavity filling. The mold temperature must be increased by 10-30°C. For example, for aluminum alloy vacuum die-casting, the mold temperature should be controlled between 220-280°C to minimize the chilling effect of the molten metal in the vacuum environment. The hold time should be extended to 2-8 seconds to allow the molten metal to fully compensate for shrinkage and reduce shrinkage cavities.

The quality advantages of vacuum die-casting are primarily reflected in low porosity and high reliability. Through vacuum degassing, the porosity of die-casting parts can be reduced from 3% to 5% (compared to conventional die-casting) to below 0.5%. The pores are small (≤0.1mm) and evenly distributed, eliminating the formation of continuous gas channels. This low porosity significantly improves the airtightness of die-casting parts. For example, the leakage rate of automotive transmission housings has been reduced from 5% (compared to conventional die-casting) to below 0.1%, fully meeting the requirements of high-pressure hydraulic systems. Furthermore, the mechanical properties of vacuum die-casting parts are improved, with tensile strength increased by 5% to 15% and elongation by 10% to 30%. The performance fluctuation range is also reduced (standard deviation ≤ 5MPa), resulting in better product consistency. Furthermore, vacuum die-casting reduces the formation of oxide inclusions, resulting in superior surface quality of die-casting parts and an increase in the electroplating pass rate to over 95%.

Vacuum die-casting is continuously expanding its application areas, demonstrating its unique value across multiple industrial sectors. The automotive industry is the largest market, with parts such as engine cylinder heads and intake manifolds made from vacuum-die-cast aluminum alloys achieving airtightness (no leakage for three minutes at 0.1 MPa). Vacuum die-casting also achieves pore-free molding of complex flow paths in motor housings and battery cooling plates for new energy vehicles, improving heat dissipation efficiency by 15%. In the home appliance industry, vacuum die-casting is used for cylinder blocks in air-conditioning compressors, minimizing compression efficiency losses caused by pores and reducing energy consumption by 8%. Vacuum die-casting ensures airtightness at pressures above 30 MPa for high-pressure components in the hydraulic industry, extending their service life to twice that of traditional castings. Advances in vacuum technology have led to the development of large-scale vacuum die-casting molds (such as those for 5,000-ton die-casting machines). Vacuum die-casting is increasingly being applied to large structural components, such as wheel hubs for wind turbines and bogies for rail transit, driving the development of high-end equipment manufacturing.