Common troubleshooting methods for cold chamber die casting machines

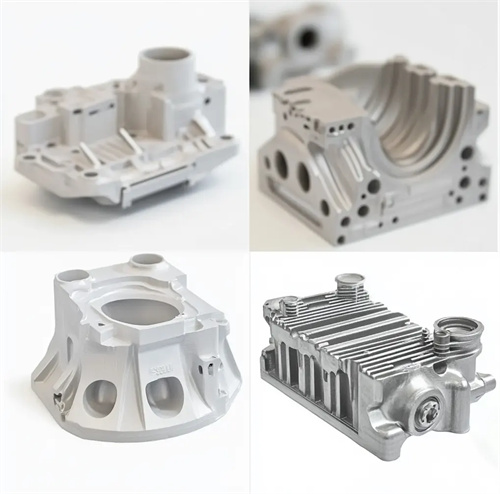

Cold-chamber die-casting machines are widely used in industrial production due to their suitability for die-casting high-melting-point alloys (such as aluminum and copper alloys). However, their complex structure leads to significant differences in failure types compared to hot-chamber die-casting machines. Common failures occur primarily in the injection molding system, die clamping mechanism, hydraulic system, and electrical control system. Rapid troubleshooting of these issues requires a comprehensive understanding of the equipment’s structural characteristics and operating principles to avoid escalating problems through blind manipulation. Troubleshooting should follow a “observe the phenomenon – analyze the cause – conduct step-by-step troubleshooting – verify the results” process, ensuring each step is clearly targeted.

Failure of the injection system is the most common problem in cold chamber die-casting machines, and its main manifestations are injection jamming, molten metal splashing, and weak injection. Injection jamming is often caused by a small gap between the pressure chamber and the injection rod or the entry of foreign objects. First, check the interior of the pressure chamber for solidified metal or scale, and clean it with special tools. Measure the clearance between the injection rod and the pressure chamber; it should normally be 0.1-0.2mm. If the clearance is too small, the worn parts must be replaced, while if it is too large, it will cause molten metal leakage. Molten metal splashing is usually caused by the injection punch starting speed being too fast or the pressure chamber being filled too much. Adjust the injection slow section speed (down to 0.5-1m/s) and control the molten metal filling volume to 70-80% of the pressure chamber capacity. If splashing still occurs, check the injection punch seal for wear and replace it with a high-temperature resistant seal. When the injection pressure is weak, shrinkage cavities are more likely to form in the casting. First, check whether the injection pressure has reached the set value (for example, 30-80 MPa for aluminum alloy die casting). Insufficient pressure may indicate a stuck injection valve; disassemble and clean the valve core. If the pressure is normal, check the accumulator pressure. If it is below the set value, add nitrogen to the rated pressure (for example, 12 MPa). A cold chamber die-casting machine at a factory frequently stuck during injection. Inspection revealed severe wear on the inner wall of the injection chamber. After replacing the injection chamber, the problem was resolved.

Malfunctions in the mold clamping mechanism directly affect the dimensional accuracy of castings. Common issues include insufficient clamping force, abnormal mold opening and closing motion, and mold collisions. Insufficient clamping force can lead to leakage on the parting surface and flash. First, check the clamping parameters, such as whether the clamping pressure and holding time meet process requirements. If the parameters are correct, inspect the toggle mechanism for wear and measure the hinge sleeve clearance. If it exceeds 0.2mm, replace the sleeve and apply grease to reduce friction. Abnormal mold opening and closing motion, such as fluctuating speeds, is often caused by improper flow valve adjustment or hydraulic oil contamination. Recalibrate the flow valve, replace the hydraulic oil, and clean the filter. If the movement is slow, check the guide rail lubrication and add special guide rail oil to ensure smooth movement. Mold collisions are often caused by excessive closing speed or worn locating pins. Reduce the slow closing speed (set to 1-2m/s). Check the clearance between the locating pin and the locating hole. If it exceeds 0.1mm, replace the locating pin and install an anti-collision device if necessary. A factory experienced a decrease in the clamping force due to wear of the clamping mechanism elbow, resulting in a flash rate of 20% on the castings. After replacing the bushing, the flash rate dropped to below 1%.

Hydraulic system failures in cold-chamber die-casting machines manifest as abnormal system pressure, excessive oil temperature, and delayed actuator operation. If system pressure is unstable, first check the relief valve for sticking, disassemble and clean the valve core, and adjust the pressure to the rated value (e.g., 16 MPa). If the pressure continues to drop, check the hydraulic pump suction line for leaks. Apply soapy water to the joints. Bubbling indicates the leak, and tighten or replace the seals. Excessive oil temperature (over 55°C) accelerates hydraulic oil aging. Check the cooling system, clean the cooler for scale, and ensure sufficient cooling water flow (pressure 0.2-0.4 MPa). If cooling is normal, check the hydraulic pump and motor for mismatching. Overloaded operation can cause a sudden increase in oil temperature, requiring re-matching of power parameters. Delayed operation of actuators, such as the clamping cylinder, is often caused by air in the cylinder. Open the exhaust valve to vent air. Also, check the cylinder seals for deterioration and replace them to eliminate internal leaks. The hydraulic system oil temperature of a die-casting machine was consistently high. Inspection revealed a clogged cooler. After cleaning, the oil temperature dropped to the normal range of 45°C.

Failures in the electrical control system can cause equipment malfunction. Common symptoms include program runaway, sensor failure, and motor failure. When program runaway occurs, the equipment operates in the wrong order. Check the PLC program for tampering or corruption, re-install the backup program, and calibrate the input and output modules. If the problem recurs, check the battery level. If low, replace the PLC battery to prevent program loss. For sensor failure, such as a position sensor with no signal, first check for loose connections and use a multimeter to measure the signal line continuity. If broken, rewire the wires. Sensor failures, such as magnetic scales and proximity switches commonly used in die-casting machines, require replacement. After replacement, recalibrate the zero point. For motor failures, such as a mold-locking motor that stops rotating, check the power supply voltage and contactor contacts for corrosion. Severe corrosion requires replacement. If the motor winding is short-circuited or grounded, replace the motor and inspect the insulation of the power supply lines. A factory’s cold-chamber die-casting machine experienced a failure in shot position detection due to a faulty proximity switch. Normal operation resumed after the switch was replaced.

Failures in the molten metal scooping and delivery systems are common in horizontal cold chamber die-casting machines, impacting production continuity. Inaccurate positioning of the scooping robot can cause molten metal to spill. Check the robot’s motion trajectory parameters and recalibrate the scooping position to ensure the scoop is aligned with the center of the die-casting chamber. If the robot arm is loose, tighten the connecting bolts and replace worn bearings. Insufficient metal feeding into the die-casting chamber can lead to under-casting. Adjust the scooping volume to ensure that the molten metal fills 70-80% of the die-casting chamber. Also, check the scoop for wear; if the volume decreases, replace it. Severe oxidation during molten metal delivery requires checking that the scoop is adequately preheated. Failure to preheat can cause the molten metal to cool too quickly. Set the preheating temperature (approximately 200°C for aluminum alloys) and shorten the scooping time to minimize air contact. At one plant, molten metal waste reached 15% due to misaligned positioning of the scooping robot. After recalibration, the waste rate dropped to 3%.