Common troubleshooting methods for hot chamber die casting machines

Hot chamber die-casting machines are widely used in die-casting low-melting-point alloys such as zinc alloys due to their compact structure and high production efficiency. However, they are prone to various faults during long-term operation, and rapid and accurate troubleshooting is crucial to ensuring continuous production. Failures in hot chamber die-casting machines primarily occur in the injection system, furnace system, hydraulic system, and electrical system. Each fault has its own typical characteristics and troubleshooting methods. Mastering these methods can significantly reduce downtime and production losses. Troubleshooting should adhere to the principle of “easy first, difficult later, external first, internal later.” Start by checking visible external factors, such as pipe connections and parameter settings, and then gradually delve into internal components to avoid reckless disassembly and secondary damage.

Injection system failure is the most common problem with hot chamber die casting machines, manifesting primarily as insufficient injection force, abnormal injection speed, and poor metal filling. Insufficient injection force can lead to shrinkage and underfilling of castings. First, check the injection pressure parameters for correct settings. If the setting is too low, adjust it to process requirements. If the parameters are normal, check the hydraulic system pressure for compliance. A malfunctioning relief valve may be preventing pressure from building up. Disassemble the relief valve and clean or replace the valve core. Too slow an injection speed can cause the metal to cool too quickly. Check the flow valve for blockage and clean the valve core or replace the flow valve. Too fast an injection speed may indicate servo valve failure, requiring calibration or replacement of the control module. If metal filling is poor, first check the injection chamber and nozzle for blockage and clean any scale and solidified metal. Next, check the ingates for undersize or blockage. If necessary, enlarge the ingates or remove any debris. A hot chamber die casting machine at a certain factory experienced insufficient injection force. Inspection revealed a worn and leaking seal in the injection cylinder. After replacing the seal, pressure returned to normal.

Furnace system failures directly impact molten metal quality. Common problems include abnormal furnace temperatures, oxidation, and leakage. Excessively high furnace temperatures can lead to alloying burnout, while excessively low temperatures can result in poor molten metal fluidity. First, check the thermostat settings and sensor contact. If the sensor is faulty, replace it. If the temperature control is normal, check the heating element for damage and measure the resistance with a multimeter. Damaged heating elements should be replaced promptly to ensure uniform heating. Severe oxidation of the molten metal can lead to inclusions in the casting, often caused by poor furnace sealing or insufficient shielding gas. Check the furnace cover for seals and ensure the shielding gas (such as nitrogen) flow rate is sufficient (usually 5-10 L/min). Adjust the flow rate or replace the gasket. Furnace leakage often occurs between the crucible and the heating element. Check the crucible for cracks; if any, replace it. Deterioration of the sealing rubber ring can also cause leakage, which can be resolved by replacing it with a high-temperature-resistant rubber ring. In a factory’s furnace, local damage to the heating element caused uneven temperature and large fluctuations in molten metal fluidity. Replacing the heating element restored normal operation.

Hydraulic system failures in hot chamber die-casting machines manifest as sluggish movement, pressure fluctuations, and oil leaks. Sluggish movement (such as slow mold opening and closing) is often due to insufficient hydraulic oil flow. Check the hydraulic pump for wear (increased noise, decreased pressure). Severe wear requires repair or replacement. A clogged filter can also cause insufficient flow; clean or replace the filter element. Pressure fluctuations may be caused by air mixing into the hydraulic oil. Open the system bleed valve to vent air, check the suction line for leaks (such as loose joints), tighten the joints, or replace the seals. Oil leakage is a common fault. Check the pipe joints for looseness and the seals for aging. Tighten the joints or replace the seals. Cylinder piston rod oil leakage is often caused by worn dust rings and seals. Disassemble the cylinder and replace the seals, taking care to avoid damaging the seals during installation. A die-casting machine was experiencing slow mold opening and closing. Inspection revealed a clogged hydraulic pump suction filter. Cleaning the filter restored normal operation.

Electrical system failures can cause equipment to fail to start properly or experience uncontrolled operation. Common issues include button malfunction, motor stalling, and PLC alarms. Button malfunction is often caused by oxidized or damaged contacts. Disassemble the button box and clean the contacts or replace the button. A failed emergency stop button can also prevent the equipment from starting. Check the emergency stop button to ensure it is fully reset. If the motor is stalled, first check the power supply and fuse for blown conditions and replace them. Then, check the contactor for energizing and corrosion. Severe corrosion requires replacement. Motor faults (such as winding shorts) require a multimeter and the motor may need to be replaced or rewound. If a PLC alarm sounds, check the corresponding alarm code for the cause of the fault. For example, “abnormal shot position” may indicate a position sensor failure; check the sensor wiring or replace it. “Oil temperature too high” indicates an error in the cooling system, clean the cooler, or replace the cooling pump. A hot chamber die-casting machine at a certain factory experienced an unresponsive shot due to a faulty PLC input module. Replacing the module restored normal operation.

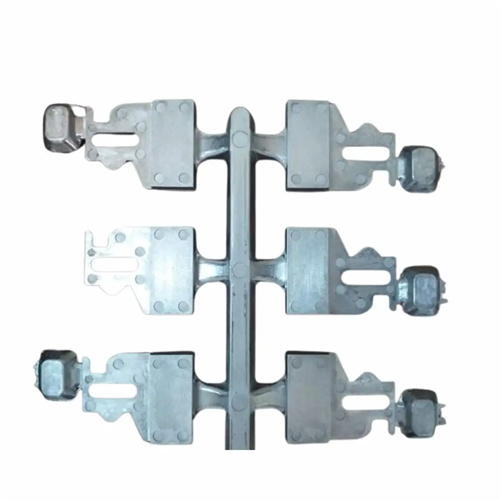

Faults related to the mold and nozzle should not be ignored, as they mainly affect the quality of castings and production efficiency. Clogged or worn nozzles can lead to poor flow of molten metal, insufficient pouring or cold shut. Clean the solidified metal in the nozzle regularly, check the nozzle wear, and replace the nozzle if the wear is severe. Ensure that the clearance with the mold sprue sleeve is 0.1-0.2mm. Leakage on the mold parting surface will cause flash. Check whether the clamping force is sufficient and whether there are foreign objects on the mold parting surface. Clean the parting surface or increase the clamping force. Wear on the mold guide pins and sleeves can also lead to poor mold closing. Replace the guide pins and sleeves and add grease. Ejector failures such as ejection failure or reset failure should be checked. Check whether the ejector cylinder is leaking and whether the ejector limit switch is malfunctioning. Replace the seal or limit switch. A factory had a flash caused by leakage of molten metal due to excessive clearance between the nozzle and the mold sprue sleeve. After replacing the nozzle and adjusting the clearance, the flash problem was completely solved.

Verification and preventive measures after troubleshooting are equally important. After troubleshooting, conduct a trial run to confirm that the fault has been resolved and parameters have returned to normal. Run 10-20 molds continuously, observing the equipment’s operating status and casting quality to ensure there are no anomalies. Record the fault symptoms, troubleshooting process, and causes, and include them in a troubleshooting case library for future reference. For recurring faults, analyze the root cause and implement preventative measures. For example, if frequent nozzle wear is the cause of a failure, consider replacing it with a wear-resistant material to extend its service life. For faults caused by inadequate maintenance, strengthen maintenance and shorten the inspection cycle of related components. Through continuous improvement, gradually reduce the failure rate and improve the operational stability and production efficiency of the hot chamber die-casting machine.