Die castings reduce core pulling areas and prevent deformation

In die-casting design, the number of core-pulling locations directly impacts mold complexity and production costs. Excessive core-pulling mechanisms not only increase mold manufacturing costs but also reduce production efficiency and increase the risk of failure. Furthermore, the casting is susceptible to deformation due to uneven force during the core-pulling process. Therefore, minimizing the number of core-pulling locations and implementing anti-deformation measures are key areas for optimal design. Through structural optimization, process adjustments, and material selection, the need for core-pulling can be significantly reduced while maintaining product functionality, while also improving the dimensional stability of the casting.

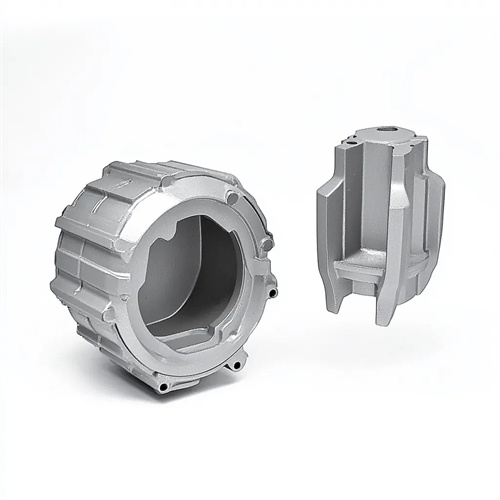

The key to reducing the number of core-pulling locations is to avoid complex features through structural optimization, prioritizing parting surface molding over core-pulling. For inclined holes or bosses, if the angle is ≤5°, the mold parting surface can be adjusted so that the feature is molded along the parting surface, eliminating the need for an inclined core-pulling mechanism. A housing with a 3° inclined boss originally required an inclined core-pulling design, but after adjusting the parting surface, it was directly molded, reducing mold costs by 15%. Symmetrical structural design can reduce asymmetric core-pulling by combining multiple core-pulling directions into a single direction. For example, by changing asymmetrical bosses on both sides to a symmetrical distribution, the number of core-pulling mechanisms can be reduced from two to one. A motor end cover with a symmetrical design reduced the number of core-pulling mechanisms by 50%. By converting a closed structure to an open one, such as changing an annular groove to a U-shaped groove, inward core-pulling can be avoided. After the annular oil groove of a gearbox was changed to a U-shape, inward core-pulling was eliminated, extending mold life by 30%.

Leveraging the casting’s inherent structure to achieve core-free molding is a highly efficient method. Using inclined demolding instead of core pulling, for relatively low bosses (less than 10mm), a sufficient ejection angle (≥3°) allows the boss to be ejected with the entire casting, eliminating the need for core pulling. An 8mm-high boss on a cover plate was demolded without core pulling using a 3° angle, improving production efficiency by 10%. Replacing a deep cavity with a stepped, shallow cavity reduces the core pulling depth. For a cylindrical component originally 50mm deep and requiring a long core pull, replacing it with three 15mm stepped cavities shortened the core pulling length to 20mm, improving mechanical stability. Using a combination molding approach, complex features requiring core pulling are split into multiple parts, which are then assembled to achieve functionality. For example, a valve body requiring three core pulls was replaced with two separate parts. After assembly, performance remained unchanged, while mold complexity was significantly reduced.

To prevent deformation caused by core pulling, the design of the core pulling mechanism must be optimized to ensure uniform force. The core pulling force distribution should match the rigidity of the casting, and auxiliary supports should be provided at weak points. A thin-walled part was prone to bending during core pulling. After adding two auxiliary ejectors, the deformation was reduced from 0.5mm to 0.1mm. The core pulling speed is controlled in stages, with a low speed ( 5-10mm/s) in the initial stage to avoid impact, and then a high speed (20-30mm/s) to improve efficiency. The deformation rate of a zinc alloy part was reduced from 8% to 1% through segmented core pulling. The core pulling sequence is optimized, first pulling out the more rigid parts of the casting, then the weak parts, such as pulling out the end boss first, then the middle groove, so that the stress is gradually released. A certain bracket eliminated distortion by adjusting the core pulling sequence.

Material selection and process parameters are crucial for preventing deformation. High-strength alloys can improve deformation resistance. For thin-walled parts requiring core pulling, aluminum alloys with a tensile strength ≥200 MPa (such as 6061) are used instead of ADC12. Switching to a high-strength alloy for a mobile phone midframe reduced core pulling deformation by 60%. Appropriately increasing mold temperature (for example, from 200°C to 230°C for an aluminum alloy mold) reduces the cooling rate of the casting and reduces internal stress. For a cover plate, using a heated mold, the flatness error after core pulling was reduced by 0.2mm. Increasing the holding time (by 20-30%) results in more complete crystallization of the casting, a denser structure, and enhanced deformation resistance. For a thick-walled part, increasing the holding time from 3 seconds to 4 seconds significantly reduced core pulling deformation.

Auxiliary measures to prevent deformation include optimizing demolding and post-processing processes, performing immediate shaping after core pulling, and utilizing specialized tooling to correct deformation. For example, the straightness of a long rod casting was reduced from 1mm/m to 0.3mm/m after core pulling using a straightening tool. Aging treatment eliminates residual stress from core pulling. Heating the casting to 120-180°C for 2-4 hours reduced residual stress by 40% and improved dimensional stability in an aluminum alloy bracket after aging. Simulation software is used to predict core pulling deformation, and Moldflow analyzes stress distribution during the core pulling process to proactively optimize structural weaknesses. Simulations have shown that adding two reinforcing ribs to a complex casting reduced core pulling deformation by 70%.