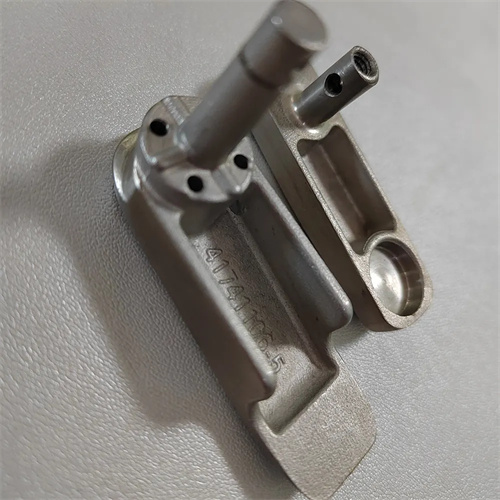

Main components of the core pulling mechanism on the die casting die side

The side core pulling mechanism of a die-casting mold is a key device for forming side holes, undercuts, or complex side structures in castings. Its main components include a core pulling power source, a transmission mechanism, a core assembly, a guide device, and a locking mechanism. These components work together to achieve lateral extraction and repositioning of the core. When a casting has concave and convex structures perpendicular to the mold opening direction, the side core pulling mechanism must be used to extract the core before the mold is opened to prevent it from being retained or damaged. The design of the side core pulling mechanism must meet the requirements of smooth movement, precise positioning, and sufficient strength, which directly affects the mold life and the dimensional accuracy of the casting.

The core pulling power source is the driving core of the side core pulling mechanism, providing the force and stroke required for core extraction. Common types include inclined guide pins, hydraulic cylinders, pneumatic cylinders, and rack-and-pinion mechanisms. The inclined guide pin power source utilizes the relative motion during mold opening to drive the core pulling. Its simple structure and low cost make it suitable for applications with low core pulling force (less than 5kN) and short stroke (less than 50mm). The hydraulic cylinder power source provides stable power through hydraulic oil, capable of core pulling forces exceeding 50kN and flexible stroke adjustment, making it suitable for core pulling of large and complex castings. The power source selection should be determined based on the core pulling force calculation results. The core pulling force F must satisfy the following equation: F ≥ K × A × p (K is the safety factor, A is the projected core area, and p is the die casting pressure ratio) to ensure that the core does not shift under the pressure of the molten metal.

The transmission mechanism is responsible for converting the motion of the power source into lateral extraction of the core. The combination of an inclined guide pin and a slider is the most typical form of transmission. The inclined guide pin is fixed to the fixed mold. When the mold is opened, the slider is driven by an oblique angle (usually 15°-25°) to move the core. Too large an angle can easily cause it to get stuck, while too small an angle will result in insufficient core pulling stroke. For long-stroke core pulling, a lever drive or connecting rod mechanism can be used to reduce the load on the power source through the lever arm amplification effect. The clearance of the transmission mechanism must be strictly controlled. The clearance between the slider and the guide groove should be 0.02mm-0.05mm to ensure smooth and unobstructed movement. In addition, the transmission mechanism must be equipped with a lubrication device, such as an oil tank or grease nipple, to reduce wear from long-term movement.

The core assembly, consisting of the forming core, core retaining plate, and connecting bolts, directly determines the accuracy of the casting’s lateral structure. The forming core must be made of high-strength hot-work die steel (such as H13) and hardened to 50-55 HRC to withstand the impact and pressure of molten metal. The core and retaining plate are connected by an interference fit or bolted fastening. Locating pins ensure core position accuracy, with a coaxiality error of no more than 0.03mm. For slender cores, auxiliary supports are required to prevent bending and deformation during die casting. The core’s surface roughness must be below Ra0.8μm to avoid surface scratches on the casting.

The guiding device and locking mechanism are important parts to ensure the reliability of the side core pulling mechanism. The guiding device consists of a guide groove and a slider. The guide groove adopts a T-shaped or dovetail structure, which guides and positions the lateral movement of the slider. Its parallelism error is controlled within 0.02mm/100mm. The locking mechanism locks the slider during mold closing and die casting to prevent the core from retreating due to the pressure of the molten metal. Common ones include wedge blocks and locking pins. The bevel angle of the wedge block should be 2°-3° larger than the inclined guide column to ensure that the slider can be completely locked when the mold is closed. The locking surface needs to be quenched to improve wear resistance. When the mold is opened, the wedge block is first separated from the slider, and then the core pulling power source drives the slider to move to avoid interference. Through the precise coordination of each component, the side core pulling mechanism can achieve efficient and stable core pulling action to meet the molding requirements of complex castings.