Die casting die ejection force and push pressure

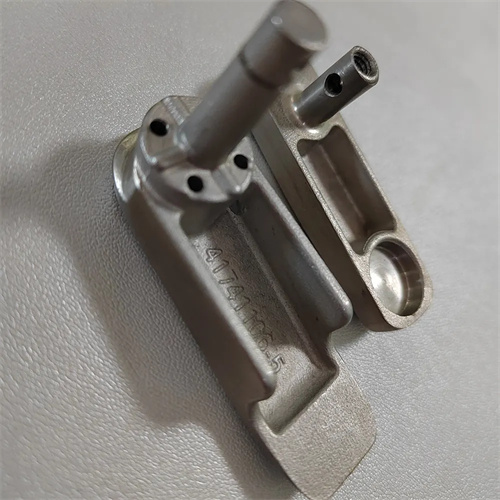

The ejection force and pressure of a die-casting mold are core parameters in ejection mechanism design, directly determining the selection of the power source and the strength design of the actuator components. The ejection force is the minimum force required to release the die-casting from the core, while the pressure is the pressure per unit area experienced by the die-casting during ejection. Both must be controlled within a reasonable range to ensure smooth demolding while avoiding deformation or damage to the die-casting. Accurately calculating these two parameters is essential for reliable ejection mechanism operation, requiring comprehensive consideration of the casting material, structural characteristics, core surface condition, and die-casting process parameters.

The main components of the ejection force include the holding force of the casting on the core, surface friction, and the resistance to deformation of the casting. Holding force is the most important component, generated by the solidification shrinkage of the molten metal. The formula for calculating holding force is Fhold = σshrink × A × μ, where σshrink is the shrinkage stress of the casting material (80-120 MPa for aluminum alloys, 60-90 MPa for zinc alloys, and 100-150 MPa for copper alloys), A is the contact area between the casting and the core, and μ is the coefficient of friction (0.1-0.2 for smooth surfaces and 0.2-0.3 for rough surfaces). For example, if the contact area between an aluminum alloy casting and the core is 500 cm² and the surface roughness Ra is 1.6 μm (μ = 0.15), then Fhold = 100 × 500 × 100 × 0.15 = 750,000 N (750 kN). The actual ejection force F push = K × F hold, where K is the safety factor, which is 1.2-2.0 according to the complexity of the casting. Therefore, the ejection force of this casting needs to be 900-1500kN, and a large hydraulic ejection system needs to be selected.

Surface friction is proportional to the holding force and coefficient of friction, and is also affected by the core surface roughness and draft angle. The smoother the core surface (Ra ≤ 0.8 μm), the lower the coefficient of friction, and the correspondingly lower the ejection force. The greater the draft angle, the lower the friction. Generally, each 1° increase in draft angle reduces friction by 10%-15%. For vertical surfaces without a draft angle, the ejection force should be increased appropriately, with a safety factor of 1.8-2.0. For surfaces with a draft angle of 3° or greater, the safety factor can be reduced to 1.2-1.5. For example, for copper alloy castings with vertical surfaces, since there is no draft and the material has a high coefficient of friction, the ejection force should be calculated as twice the holding force. For aluminum alloy castings with a 5° draft, the ejection force can be calculated as 1.3 times the holding force.

Casting deformation resistance is an additional component of ejection force, primarily affecting thin-walled, slender, and irregularly shaped parts. These structures are prone to elastic deformation during ejection, increasing demolding resistance. Calculating deformation resistance is complex and is typically estimated using the empirical formula: Fchange = E×ε×A, where E is the material’s elastic modulus (70 GPa for aluminum alloys and 90 GPa for zinc alloys), ε is the elastic strain (generally ≤ 0.001), and A is the cross-sectional area of the deformation zone. For example, for a thin-walled aluminum alloy part with a thickness of 2 mm and a width of 50 mm, and a deformation zone area of 100 mm², Fchange = 70 × 10³ × 0.001 × 100 = 7000 N (7 kN), which must be factored into the total ejection force. For castings with complex shapes, deformation resistance can be estimated as 5%-15% of the clamping force to ensure sufficient ejection force.

The push pressure refers to the pressure per unit area exerted by the ejector on the die-casting surface. It must be controlled within the material’s allowable compressive strength to prevent surface indentation or plastic deformation. The push pressure is calculated as P push = F push / A push, where A push is the total contact area between the ejector and the casting. The allowable push pressure for aluminum alloys is 50-100 MPa, for zinc alloys 30-80 MPa, and for copper alloys 80-150 MPa. For example, if the total ejection force is 1000 kN and the ejector contact area is 200 cm² (20,000 mm²), then P push = 1000 × 10³/20,000 = 50 MPa, which is within the allowable range for aluminum alloys. If the push pressure exceeds the allowable value, the number of ejection points or the ejection area must be increased. For example, increasing the contact area to 300 cm² can reduce P push to 33 MPa, providing greater safety and reliability.

The calibration of ejection force and pressure must be adjusted based on production practice. Theoretical calculations may differ from actual operating conditions, requiring optimization through trial mold verification. If the casting is difficult to demold or the core exhibits scratches during trial mold testing, this indicates insufficient ejection force. Check to see if deformation resistance is overlooked or the friction coefficient is too low. If the ejection area dents or deforms, this indicates excessive pressure, requiring an increase in the ejection area or adjustment of the ejection point distribution. For example, during a trial mold test of a zinc alloy shell, the ejection area dented. Inspection revealed a pressure of 90 MPa (exceeding the allowable value of 80 MPa). By adding four ejector pins, the contact area was increased from 100 cm² to 130 cm², reducing the pressure to 70 MPa and resolving the issue. Only by combining theoretical calculation with trial mold verification can reasonable ejection force and pressure parameters be determined to ensure high-quality demolding of die-cast parts.