Composition and classification of die-casting mold ejection mechanism

The ejection mechanism of a die-casting mold is a key device for smoothly ejecting die-casting parts from the mold. Its primary function is to eject the solidified die-casting from the core or cavity after mold opening, ensuring the product is undeformed and undamaged. The ejection mechanism’s composition must balance uniform ejection force, controllable ejection speed, and reliable operation. It is categorized based on power source, ejection method, and structural form. A properly designed ejection mechanism not only improves production efficiency but also reduces the workload associated with subsequent finishing of die-casting parts, making it a crucial element in die-casting mold design.

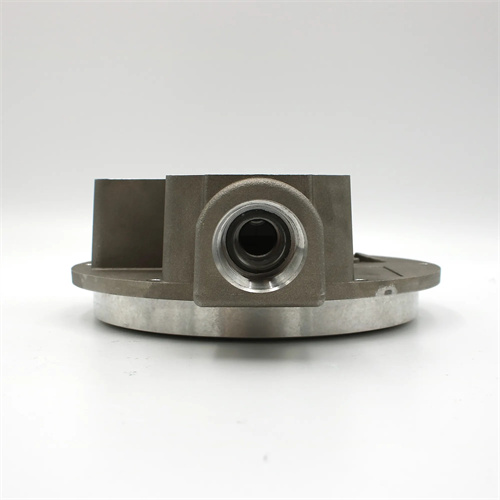

The basic components of the ejection mechanism include an ejector actuator, a transmission component, a guide component, and a reset component. The ejector actuators directly contact the die-cast part and commonly include ejector pins, ejector plates, ejector tubes, and ejector blocks. Ejector pins are suitable for flat surfaces or shallow cavities, with a diameter of 3-10mm and a distribution density determined by the weight of the die-cast part, with a minimum of one per 50cm². Ejector plates (push plates) are suitable for large, thin-walled parts, with a thickness of 8-15mm and a contact area of at least 80% with the die-cast part to prevent part deformation during ejection. Ejector tubes are suitable for ejecting cylindrical cores, with an inner diameter 1-2mm larger than the core diameter to ensure smooth engagement. Ejector blocks are used for ejecting irregularly shaped parts, and their shape matches the local contours of the die-cast part to ensure uniform ejection force. The actuators are made of H13 steel or Cr12MoV, with a hardness of 50-55HRC as hardened, and a surface roughness of Ra ≤ 0.8μm to avoid scratching the part surface.

The transmission component, which primarily consists of a push rod, push tube, and wedge-shaped transmission mechanism, is responsible for transmitting power to the actuator. The push rod connects the ejector actuator to the power source. Its diameter ranges from 8-20mm, and its length depends on the mold thickness. It is made of quenched and tempered 45 steel (hardness 28-32 HRC), with a straightness tolerance of ≤0.05mm/m, ensuring smooth ejection. The push tube drives the ejector tube, maintaining a clearance of 0.02-0.04mm to prevent molten metal intrusion. The wedge-shaped transmission mechanism is used for ejection after side core pulling. Its inclined surface converts vertical motion into horizontal ejection, making it suitable for die-castings with undercuts. The wedge angle is typically 15°-25°, ensuring a force transmission efficiency of ≥80%. The transmission components are connected using threads or pins. The tightening torque for threaded connections is determined by diameter; for M10 bolts, the tightening torque is 30-40N · m , ensuring reliable transmission.

The guide components ensure the ejection mechanism’s precise movement and prevent deflection during ejection. They primarily consist of a guide pin, guide sleeve, and guide plate. The guide pin has a diameter of 10-25mm and a length 20-30mm greater than the maximum ejection stroke. Made of 20CrMnTi carburized and hardened (hardness 58-62 HRC), the surface roughness Ra ≤ 0.4μm. The guide sleeve, made of tin bronze ZCuSn10Pb1, has a clearance of 0.01-0.03mm between the guide pin and the guide sleeve, and an inner oil groove ensures adequate lubrication. The guide plate has a thickness of 10-20mm, a flatness tolerance of ≤0.02mm/100mm, and a perpendicularity tolerance of ≤0.01mm/100mm relative to the guide pin, ensuring axial movement of the ejection mechanism. The guide components must be arranged symmetrically, with a maximum distance of no more than 100mm from the ejector rod to prevent torque generated during ejection that could cause deformation of the mechanism.

The reset component is used to return the ejector mechanism to its initial position before mold closing. Common reset components include a reset spring, reset rod, and hydraulic cylinder. The reset spring is a cylindrical helical compression spring with a wire diameter of 2-5mm, a free length of 30-80mm, and a pre-compression of 10-20mm to ensure uniform reset force. The spring material is 65Mn and the operating temperature is ≤200°C. The reset rod is installed at the four corners of the ejector plate and is 0.1-0.2mm longer than the ejector pin to ensure that it contacts the fixed mold first, forcing reset. The hydraulic cylinder reset is suitable for large molds. It has a cylinder diameter of 20-50mm, an operating pressure of 0.5-0.8MPa, a reset accuracy of ≤0.05mm, and a travel switch to control the reset endpoint. The reset component must ensure that the mechanism is reset into place, with a clearance of ≤0.02mm from the fixed mold to prevent collision during mold closing.

Ejection mechanisms can be categorized in various ways, including manual, mechanical, and hydraulic according to their power source. Manual ejection is driven by a handle or screw and is suitable for small, simple molds, with an ejection force of ≤5kN. Mechanical ejection utilizes the die-casting machine’s mold opening force via the ejector rod, with an ejection force of 5-50kN, making it suitable for small and medium-sized molds. Hydraulic ejection is driven by an independent hydraulic system, with an ejection force of 50-500kN and an adjustable speed (5-50mm/s), making it suitable for large, complex molds. Ejection direction can be categorized as axial, lateral, and combined. Axial ejection, which ejects in the direction of mold opening, is the most widely used. Lateral ejection is used for products with undercuts and requires coordination with a side core-pulling mechanism. Combined ejection combines ejection in multiple directions and is suitable for die-cast parts with complex shapes. Ejection mechanisms can be categorized by structure as simple ejector (single ejector pin), combined ejector pin and ejector plate, and specialized ejector mechanisms (screw ejector and angled ejector). Screw ejector mechanisms are used for threaded parts, with a screw driving the ejector assembly to rotate, enabling simultaneous ejection and demolding. An angled ejector mechanism is used for parts with internally angled bosses, with a slope of 10°-20°, achieving a combined ejection and core pulling action. The appropriate choice of ejector mechanism should be tailored to product characteristics and production requirements to ensure efficient and high-quality demolding of die-cast parts.