Integral and combined structures of die casting molds

Two basic die-casting mold structures are monolithic and modular. Each has unique application scenarios and technical characteristics, and the choice of monolithic structure directly affects the mold’s manufacturing cycle, cost, service life, and the quality and stability of the die-casting. Monolithic structures integrate the mold’s main components, such as the cavity and core, with the mold plate, while modular structures break the mold down into multiple modules that are assembled together. Both structures play an important role in meeting different die-casting production needs.

Monolithic molds offer excellent rigidity and high strength, making them suitable for die-casting parts with simple shapes, small dimensions, and low production volumes. For example, molds for die-cast parts such as small electrical appliance accessories and toy parts often employ a monolithic structure. The cavity and core are machined directly on the mold plate, eliminating fit errors caused by splicing. The mold plate for a monolithic mold is typically constructed from a monolithically forged alloy structural steel, such as 5CrNiMo or H13. After tempering, the mold plate achieves uniform hardness and can withstand high die-casting pressures (typically 40-80 MPa). During the manufacturing process, the monolithic structure can be formed in a single step using processes such as CNC milling and electrospark forming, reducing assembly steps and improving mold manufacturing precision. The surface roughness within the cavity can be controlled to below Ra0.8μm, ensuring excellent surface quality for the die-cast part.

However, the monolithic structure also has significant limitations. For complex or large die-casting parts, a monolithic mold can lead to a sharp increase in processing difficulty and material consumption. For example, die-casting parts with deep cavities, complex patterns, or multiple irregular holes require specialized processing equipment and tools, resulting in long processing cycles and high costs. Furthermore, the monolithic mold has poor heat dissipation performance, making it prone to thermal deformation caused by localized overheating during the die-casting process, affecting the dimensional accuracy of the die-casting. Furthermore, if the mold is partially worn or damaged, the monolithic structure requires repair or replacement, which results in high maintenance costs and is particularly unsuitable for mass production or the molding of large die-casting parts.

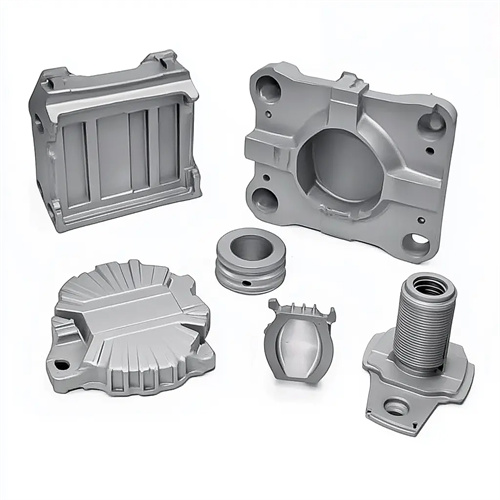

The modular structure breaks down the mold into multiple independent components, such as the mold plate, cavity insert, core insert, and guide pins and bushings. These components are then assembled into a complete mold using connectors like screws and pins. This makes it suitable for die-cast parts with complex shapes, large dimensions, or large production runs. For example, molds for large, complex die-cast parts like automotive engine blocks and transmission housings employ a modular structure. The cavity is composed of multiple inserts, each of which can be individually designed and processed according to molding requirements, reducing overall processing complexity. The modular structure offers the advantage of high flexibility, allowing for quick replacement of inserts based on die-cast part structure changes, enabling a single mold to serve multiple purposes. Furthermore, different inserts can be made of different materials. For example, the cavity surface can be made of high-temperature and wear-resistant H13 steel, while the mold plate can be made of lower-cost 45 steel or S50C steel. This ensures high performance while reducing material costs.

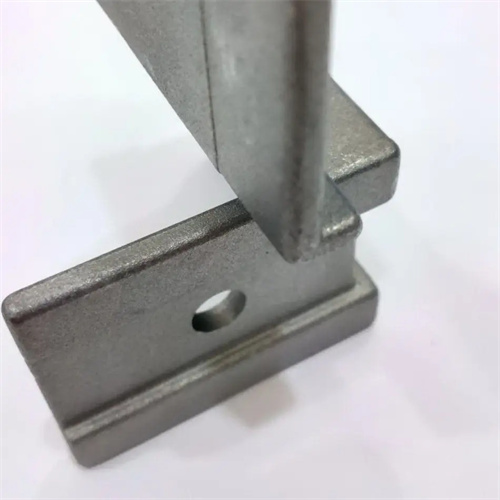

The assembly accuracy of the modular structure is key to ensuring mold performance. The positioning accuracy between each component must be controlled within 0.01-0.02mm to avoid defects such as flash and misalignment in the die-casting. Positioning methods such as stoppers, pins, or guide rails are usually used to ensure the accurate relative positioning between the inserts and the template, and between the inserts. For example, the fit between the cavity insert and the template often adopts an H7/m6 transition fit. The mating surfaces must be precision-ground to a flatness error of no more than 0.005mm/m. The joints between the inserts adopt a stepped or beveled design, which not only enhances sealing but also facilitates alignment during assembly. Another significant advantage of the modular structure is its ease of maintenance and repair. When a local insert is worn or damaged, only the corresponding component needs to be replaced, without having to scrap the entire mold. This greatly reduces maintenance costs and is particularly suitable for continuous batch production scenarios.

In practice, monolithic and modular structures are not strictly independent. Hybrid structures are often employed based on specific needs, with monolithic design used for critical molding areas and modular design for non-critical areas. For example, for die-cast parts with complex internal shapes and simple external shapes, the core can be designed as a monolithic structure to ensure molding accuracy, while the cavity can be modular to reduce processing complexity. This hybrid structure combines the advantages of both, ensuring die-casting quality while improving mold economy and flexibility. Advances in mold manufacturing technology, including the application of precision machining techniques such as 3D printing and wire EDM, have further enhanced the assembly accuracy and manufacturing efficiency of modular structures, making the molding of complex die-casting parts more precise and efficient. When selecting a mold structure, it is important to comprehensively consider factors such as the die-casting’s structural complexity, production batch size, dimensional accuracy requirements, and manufacturing costs to develop an optimal solution for high-quality, efficient, and low-cost die-casting production.