Combination of die casting mold bodies

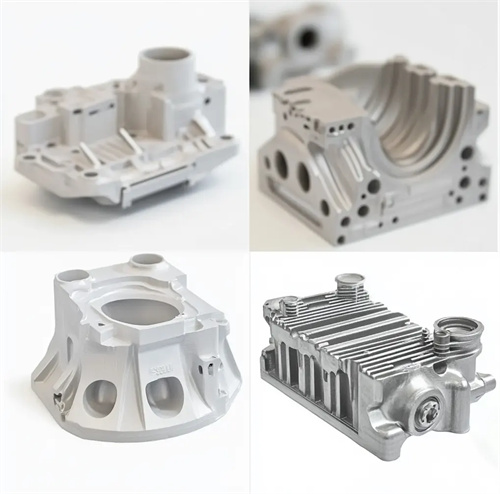

The die-casting mold body is the basic framework of the mold, including components such as the fixed die base plate, movable die base plate, template, and support plate. Its combination directly affects the mold’s rigidity, strength, ease of loading and unloading, and manufacturing cost. Common combinations include integral mold bodies, spliced mold bodies, and laminated mold bodies, each suitable for different die-casting scenarios. The integral mold body is designed to combine the fixed die base plate, fixed template or movable die base plate, and movable template into a single unit, which is forged and processed as a whole. The advantages of this form are good rigidity, high strength, and no splicing gaps. It is suitable for small die-casting molds or occasions with extremely high rigidity requirements. For example, small molds for die-casting mobile phone casings often use integral mold bodies. The fixed template and fixed die base plate are an integrated structure with a thickness of 50-80mm. This can effectively resist deformation caused by die-casting pressure (usually 40-60MPa) and ensure the overall accuracy of the mold.

A spliced mold body, composed of various mold components connected by bolts, pins, and other fasteners, is currently the most widely used mold type and is particularly suitable for medium- and large-sized die casting molds. The fixed mold portion of a spliced mold typically consists of a fixed mold base plate, a fixed mold plate, and a sprue sleeve retaining plate, while the movable mold portion comprises a movable mold plate, a support plate, and a movable mold base plate. The components are positioned using locating pins and fastened with high-strength bolts. For example, the movable mold body of an automotive wheel die casting mold utilizes a spliced structure. The movable mold plate (100-150mm thick) is connected to the support plate (80-120mm thick) using φ16mm hexagon socket bolts spaced 150-200mm apart. φ10mm locating pins (at least four per square meter of mold area) ensure accurate positioning. The advantage of the spliced mold body is that it is convenient for separate processing and heat treatment of each component. Different materials can be selected according to the stress conditions of different parts (such as H13 steel for the template and 45 steel for the seat plate), which reduces manufacturing costs and facilitates mold maintenance and component replacement.

A stacked mold is a special combination that combines two or more cavities into a single mold, making it suitable for mass production of small die-castings and significantly improving production efficiency. The fixed and movable molds of a stacked mold are divided into upper and lower layers, each with a set of cavities and cores. A special pouring system distributes the molten metal to the cavities on each layer. For example, when die-casting a small motor end cover, a two-layer stacked mold is used. A single die-casting can produce two die-castings, nearly doubling production efficiency compared to conventional molds. The stacked mold requires extremely high assembly precision. The coaxiality error of each layer’s cavity must be controlled within 0.02mm, and the pouring system’s diversion must be uniform to ensure consistent quality across all layers of the die-casting. Furthermore, the ejection mechanism of the stacked mold must be designed synchronously to ensure simultaneous demolding of each layer of the die-casting, avoiding mold deformation due to uneven force.

The guidance and positioning system of the mold assembly is crucial for ensuring assembly accuracy. Regardless of the assembly type, a comprehensive guide pin, guide bushing, or guide key structure is required. For spliced molds, 4-8 guide pins, with a diameter of 20-50mm and a length covering the entire mold opening stroke, are typically installed between the fixed and movable mold plates. The guide pins and guide bushings utilize an H7/H6 clearance fit, with a clearance of 0.01-0.03mm, to ensure accurate relative positioning of the mold components during mold opening and closing. At the joint between the mold plate and the base plate, stoppers are often used for positioning, with a stop height of 5-10mm and a clearance of 0.01-0.02mm to enhance sealing and positioning accuracy. For large molds, auxiliary guide keys with a width of 20-30mm and a clearance of 0.005-0.01mm are also required on the edge of the mold plate to further improve the overall rigidity and guiding accuracy of the mold.

The selection of mold combination should take into account the size, weight, production batch and equipment conditions of the die-casting. Small, precision die-castings should preferably use integral molds to ensure dimensional accuracy; medium and large-scale, mass-produced die-castings are suitable for spliced molds, which take into account both economy and reliability; small die-castings produced in large quantities can use laminated molds to improve production efficiency. In practical applications, a mixed combination can also be used. For example, in a spliced mold, the fixed mold plate with greater force is designed as an integral type, and the other components are spliced. This not only ensures the rigidity of key parts but also reduces overall costs. As die-casting equipment develops towards larger sizes and higher speeds, mold combination forms are also constantly innovating. For example, modular splicing technology is used to achieve rapid combination of different components through standardized interfaces, shortening the mold manufacturing cycle and improving the versatility and interchangeability of the mold.