In the rapidly evolving landscape of electrical product manufacturing, Custom Die Casting Parts have emerged as a game – changing solution for us. This manufacturing technique empowers us to produce highly specialized components that precisely meet the diverse and exacting requirements of modern electrical systems. By injecting molten metal into tailor – made molds, we can create parts with complex geometries, tight tolerances, and exceptional performance characteristics. Leveraging the precision and flexibility of custom die casting, we enhance the functionality, reliability, and safety of electrical products, catering to the needs of various industries from consumer electronics to industrial automation.

1. Custom Die Casting Parts: Fabricating Robust Enclosures for Electrical Equipment

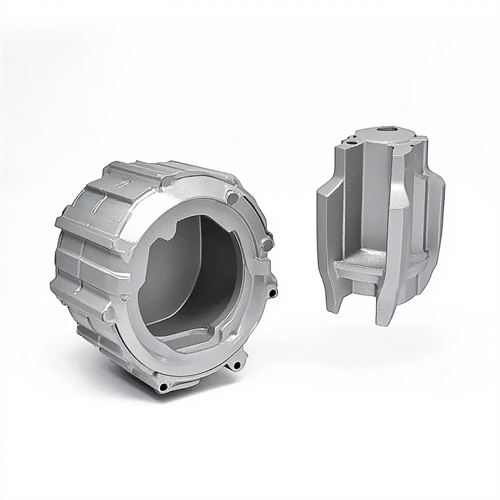

Electrical equipment often requires enclosures that provide protection against external factors such as dust, moisture, and physical impacts, while also ensuring electromagnetic compatibility. Custom Die Casting Parts allow us to design and manufacture enclosures that are not only durable but also customized to fit the specific dimensions and requirements of each piece of equipment. We start by collaborating closely with electrical engineers to understand the equipment’s operational environment, power requirements, and heat – dissipation needs. Using advanced CAD software, we create custom molds that can form enclosures with optimized structural designs, including integrated mounting points, ventilation slots, and cable entry holes.

For example, in the case of industrial control panels exposed to harsh factory environments, we produce custom die – cast enclosures made from corrosion – resistant aluminum alloys. These enclosures are designed with tight – fitting gaskets and locking mechanisms to prevent dust and moisture ingress. The high – strength nature of the die – cast material ensures that the enclosures can withstand accidental impacts from tools or equipment, protecting the sensitive electrical components inside. Additionally, the enclosures can be designed with electromagnetic shielding features to prevent interference with other electronic devices in the vicinity, ensuring the stable operation of the electrical equipment.

2. Custom Die Casting Parts: Optimizing Heat Dissipation in Power – Intensive Electrical Products

Power – intensive electrical products such as power supplies, inverters, and high – performance servers generate a significant amount of heat during operation, which can affect their performance and lifespan if not properly managed. Custom Die Casting Parts enable us to create highly efficient heat – dissipating components. We analyze the heat – generation patterns and thermal requirements of each product and design custom molds to produce heat sinks and heat – dissipating housings with optimized geometries.

For high – power server power supplies, we fabricate custom die – cast heat sinks with intricate fin arrays and micro – channel structures. These heat sinks are designed to maximize the surface area available for heat transfer, allowing for rapid dissipation of heat to the surrounding environment. The high thermal conductivity of the die – cast metal ensures that heat is quickly conducted away from the heat – generating components, such as transistors and transformers. By customizing the heat – dissipation components, we can maintain the internal temperature of the electrical products within the optimal range, improving their efficiency and extending their service life.

3. Custom Die Casting Parts: Integrating Functional Features in Electrical Connectors

Electrical connectors play a crucial role in ensuring reliable electrical connections, and Custom Die Casting Parts offer us the ability to integrate various functional features into these components. We work with electrical designers to develop custom molds that can form connectors with specific shapes, sizes, and contact configurations.

For example, in the automotive industry, we produce custom die – cast electrical connectors with integrated locking mechanisms and strain – relief features. These connectors are designed to withstand the vibrations and temperature fluctuations experienced in vehicle engines, ensuring a secure and stable electrical connection. The custom die – casting process allows us to create connectors with precise dimensions, ensuring a perfect fit with mating components. Additionally, we can incorporate shielding features into the connectors to prevent electromagnetic interference, improving the overall performance of the electrical system.

4. Custom Die Casting Parts: Enhancing Safety in Electrical Switchgear

Electrical switchgear requires components that can withstand high electrical currents and mechanical stresses while ensuring the safety of operators. Custom Die Casting Parts enable us to manufacture parts with enhanced safety features for switchgear applications. We design custom molds to produce components such as busbars, contactors, and enclosures with reinforced structures and flame – retardant materials.

For medium – voltage switchgear, we fabricate custom die – cast busbars with precise cross – sectional shapes and smooth surfaces to minimize electrical resistance and prevent overheating. The busbars are designed with integrated insulation barriers to prevent electrical arcing and short circuits. The enclosures for switchgear are also custom – made using die – casting, with features such as interlocking mechanisms to prevent accidental access to live parts and ventilation systems to dissipate heat generated during operation. These custom – designed components ensure the reliable and safe operation of electrical switchgear in various industrial and commercial applications.

5. Custom Die Casting Parts: Driving Cost – Effective and Flexible Manufacturing in Electrical Product Production

Despite the high level of customization, Custom Die Casting Parts offer significant cost – effectiveness and manufacturing flexibility in the electrical product industry. Once the custom mold is developed, the die – casting process allows for high – volume production with relatively low per – unit costs. We can also easily modify the mold design to accommodate product updates, design changes, or new feature additions, providing us with the flexibility to respond quickly to market demands.

For example, if a new electrical product requires a modified enclosure design to accommodate additional components, we can make the necessary adjustments to the custom mold without major disruptions to the production line. This flexibility reduces the time and cost associated with product development and production. Additionally, the use of standardized components within the custom die – cast parts, such as common mounting interfaces and electrical connection points, further reduces costs by enabling economies of scale in component sourcing and assembly. Overall, Custom Die Casting Parts provide us with the ability to balance customization, cost – effectiveness, and production efficiency in the highly competitive electrical product market.