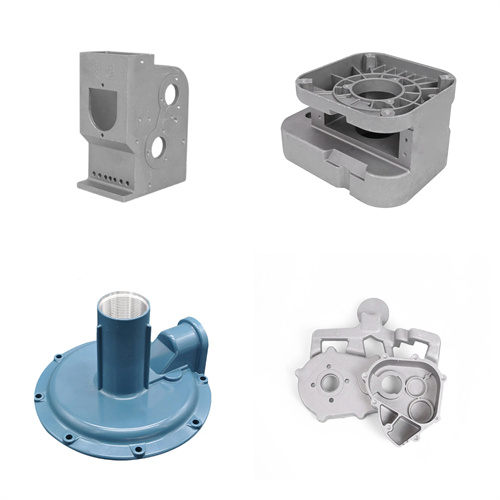

In the dynamic and creative world of the toy industry, Aluminum Die Casting has emerged as a revolutionary manufacturing approach for us. This process, which involves injecting molten aluminum into precisely crafted molds under high pressure, empowers us to produce toys that combine durability, safety, and captivating aesthetics. Leveraging the unique properties of aluminum, such as its strength, lightweight nature, and recyclability, we can create a wide range of high – quality toys that stand out in the market, catering to the diverse preferences of children and collectors alike.

1. Aluminum Die Casting: Crafting Robust and Safe Toy Vehicles

Toy vehicles have always been a staple in the toy industry, and Aluminum Die Casting enables us to manufacture models that are both robust and safe for children to play with. When creating toy cars, trucks, and trains, we prioritize the production of items that can withstand rough handling and accidental drops. We start by designing molds based on detailed blueprints of real – life vehicles, ensuring accurate replication of every curve and contour. Molten aluminum is then injected into these molds under high pressure, solidifying into toy vehicle bodies with a dense and sturdy structure.

For instance, our aluminum die – cast toy race cars are designed to endure the intense play of young enthusiasts. Whether they are being raced on tracks, crashed into obstacles, or carried around in little hands, the high strength of the aluminum ensures that the cars do not break or deform easily. Moreover, aluminum is a non – toxic material, eliminating any concerns about harmful substances leaching out during play. The smooth surfaces and rounded edges of these die – cast toy vehicles further enhance safety, preventing cuts or scratches to children’s hands. This combination of durability and safety makes our aluminum die – cast toy vehicles a favorite among parents and children alike.

2. Aluminum Die Casting: Creating Exquisite and Detailed Collectible Toys

Collectible toys require a high level of craftsmanship and detail, and Aluminum Die Casting provides us with the means to bring our most intricate designs to life. For action figures, statues, and limited – edition collectibles, we utilize this process to capture every minute feature with precision. The molds are carefully engineered to incorporate the finest details, from the texture of a superhero’s costume to the expression on a character’s face.

When producing a die – cast statue of a famous fantasy character, for example, the high – pressure injection of molten aluminum allows us to replicate the most delicate elements, such as the flowing hair, the intricate patterns on the armor, and the unique posture of the character. The result is a collectible toy that not only looks stunning but also has a solid and premium feel. The ability to apply various surface treatments, such as painting, polishing, and coating, further enhances the visual appeal of these collectibles, making them highly sought after by collectors who appreciate the artistry and quality of each piece.

3. Aluminum Die Casting: Enhancing the Playability of Interactive Toys

Interactive toys often rely on components that can move smoothly and function reliably, and Aluminum Die Casting helps us achieve this. When manufacturing toys with moving parts, such as toy construction sets with joints and connectors or mechanical toys with gears and levers, we use aluminum die – cast parts to ensure optimal performance.

In a toy construction set, the aluminum die – cast joints are designed to provide a secure connection between different pieces while allowing for a wide range of motion. These joints are strong enough to withstand repeated bending and twisting, ensuring that the construction remains stable during play. Similarly, in mechanical toys, the aluminum die – cast gears and levers are precisely crafted to mesh smoothly, enabling the toys to operate flawlessly. The lightweight nature of aluminum also makes these interactive toys easier for children to handle and manipulate, enhancing their overall play experience and promoting creativity and imagination.

4. Aluminum Die Casting: Designing Aesthetically Appealing Toy Decorations

Aesthetics play a significant role in the attractiveness of toys, and Aluminum Die Casting offers us the flexibility to create visually appealing toy decorations. For toys used in playsets, dollhouses, or as decorative pieces, we can produce components with unique shapes, colors, and finishes.

We can design molds to create aluminum die – cast chandeliers, railings, and furniture for dollhouses, adding a touch of elegance and realism. The smooth surfaces and fine details of these die – cast decorations can be further enhanced through various surface treatments. For example, anodizing can be used to create a variety of colors, while brushing can give a textured look. These aesthetically pleasing toy decorations not only enhance the visual appeal of the playsets and dollhouses but also inspire children’s creativity, allowing them to immerse themselves in imaginative play scenarios.

5. Aluminum Die Casting: Promoting Sustainable Toy Manufacturing

Sustainability is becoming increasingly important in the toy industry, and Aluminum Die Casting aligns perfectly with eco – friendly manufacturing practices. Aluminum is one of the most recyclable materials, and we can use recycled aluminum in the die – casting process without sacrificing the quality of our toys.

By incorporating recycled materials, we reduce the demand for virgin resources, conserve energy, and minimize the environmental impact of our production. Moreover, the durability of aluminum die – cast toys means that they can last for a long time, reducing the need for frequent replacements and the associated waste generation. For us as toy manufacturers, adopting Aluminum Die Casting not only helps us meet the growing consumer demand for sustainable products but also allows us to contribute to a more environmentally responsible future for the toy industry.