Oxygen-filled die casting

Oxygen-filled die casting is a die-casting process that eliminates gas defects by introducing oxygen into the mold cavity and utilizing the reaction between the molten metal and oxygen. The core principle is to replace the air in the mold cavity with oxygen before the molten metal is filled. When the hot molten metal enters the mold cavity, the oxygen reacts with elements such as aluminum and magnesium in the molten metal to form solid oxides (such as Al₂O₃ and MgO ). These oxides are dispersed throughout the die-cast part, preventing the formation of pores and thereby improving the density of the die-cast part. This process is particularly suitable for die-casting of aluminum and magnesium alloys, effectively solving the porosity problem caused by air entrapment in traditional die-casting.

The construction of an oxygenation system is crucial for oxygen die-casting, requiring precise control of the amount and timing of oxygen injection. The oxygenation system primarily consists of an oxygen cylinder, a pressure reducing valve, a flowmeter, an oxygenation valve, and an oxygen sensor. The oxygen cylinder pressure must be maintained at a stable 0.5-1 MPa. The pressure reducing valve regulates the oxygenation pressure to 0.05-0.1 MPa to prevent high-pressure oxygen from impacting the mold. The flowmeter controls the oxygen flow rate, typically 5-50 L/min, based on the cavity volume. This ensures that the air in the cavity is replaced with oxygen within 1-3 seconds (oxygen concentration ≥ 95%). The opening timing of the oxygenation valve must be precisely synchronized with the die-casting cycle. It typically opens 0.5 seconds after mold closing and before the start of injection, continues oxygenation for 0.5-2 seconds, then closes. The injection start is then delayed by 0.1-0.2 seconds to prevent oxygen backflow. The oxygen sensor, installed at the cavity exhaust port, monitors the oxygen concentration in real time to ensure effective replacement. If the concentration falls below 90%, an automatic alarm is issued, halting production.

The process parameters for oxygen-filled die-casting need to be adjusted according to the alloy type to optimize the reaction effect. For aluminum alloy die-casting, oxygen reacts with aluminum to form Al₂O₃ . This oxide has a melting point of up to 2050 °C and is highly stable, without negatively impacting the performance of the die-cast part. Therefore, the pouring temperature for oxygen-filled die-casting of aluminum alloys can be slightly higher than that of conventional die-casting ( 680-720 °C) to promote a thorough reaction between oxygen and aluminum. At the same time, the injection speed is controlled between 5 and 20 m/s to ensure uniform contact between the molten metal and the oxygen. In magnesium alloy oxygen-filled die-casting, oxygen reacts with magnesium to form MgO . Due to the higher activity of magnesium, the oxygen filling pressure needs to be lowered ( 0.03-0.08 MPa ) and the filling time shortened ( 0.3-1 second) to avoid excessive oxide inclusions caused by overreaction. In terms of mold temperature, the mold temperature of aluminum alloy oxygen-filled die casting is controlled at 200~250℃, and that of magnesium alloy is 150~200℃, which not only ensures sufficient reaction but also prevents premature solidification of the molten metal.

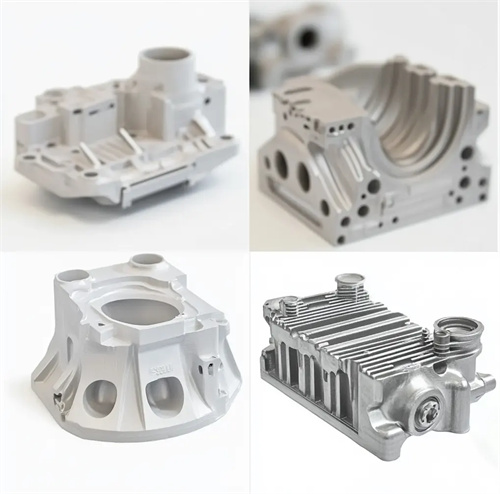

Oxygen-filled die castings are characterized by high density and excellent machinability. Because oxygen reacts with gases to form solid oxides, the porosity of die castings can be reduced to below 0.3%, while the density reaches over 99.7%, fully meeting airtightness requirements. For example, aluminum alloy oxygen-filled die castings achieve a 100% pass rate in a hydrostatic test (10 MPa, 5 minutes). Compared to vacuum die casting, the oxide particles in oxygen-filled die castings are fine (≤5 μm) and evenly distributed, minimizing the impact on mechanical properties. Oxygen-filled aluminum alloy die castings achieve tensile strengths of 280–320 MPa and elongations of 8%–12%, approaching those of semi-solid die castings. Furthermore, oxygen-filled die castings exhibit excellent machinability, with tool wear reduced by 15%–20% compared to conventional die castings, making them suitable for precision machining.

Oxygen-filled die-casting is widely used in fields requiring high airtightness, demonstrating unique technical advantages. In the automotive industry, safety components such as hydraulic steering gear housings and brake master cylinders are made from oxygen-filled die-cast aluminum alloys, ensuring leak-free operation under high pressure (above 15 MPa) and extending the service life to 1.5 times that of traditional castings. Oxygen-filled die-casting reduces porosity in the water channels of motorcycle engine cylinder blocks, improving cooling efficiency by 10% and increasing engine power by 5%. In the home appliance industry, oxygen-filled die-casting is used in washing machine clutch housings, eliminating porosity in the complex oil circuit structure and reducing operating noise by 3 decibels. In the pneumatic component sector, oxygen-filled die-cast cylinder barrels can be directly used in oil-free lubrication systems, achieving an inner wall roughness of Ra ≤ 1.6 μm without the need for additional machining. Oxygen-filled die-casting offers low equipment modification costs, requiring only the addition of an oxygen filling system to a traditional die-casting machine (at a cost approximately 50% of that of a vacuum system). This makes it suitable for technology upgrades for small and medium-sized enterprises, making it highly competitive in the production of small and medium-volume, high-precision castings.

The development direction of oxygen-filled die casting is to optimize oxide control and expand its application range. By adding trace amounts of rare earth elements (such as cerium and lanthanum), oxide particles can be refined (from 5μm to below 2μm), further reducing the impact on mechanical properties and increasing the elongation of oxygen-filled aluminum alloy die castings to over 15%. The development of intelligent oxygenation control systems, combined with cavity pressure sensors, allows for real-time adjustment of the oxygen level, resulting in more uniform oxide distribution across different parts. In the future, oxygen-filled die casting will expand to complex parts made of magnesium and zinc alloys, such as magnesium alloy automotive dashboard brackets and zinc alloy precision gears. By controlling the oxidation reaction, casting quality will be improved while reducing production costs. Furthermore, research on the integration of oxygen-filled die casting with heat treatment processes (such as the effect of T6 treatment on oxides) will further enhance the performance of die castings and expand their application in high-end applications.