Basic structure of die casting machine

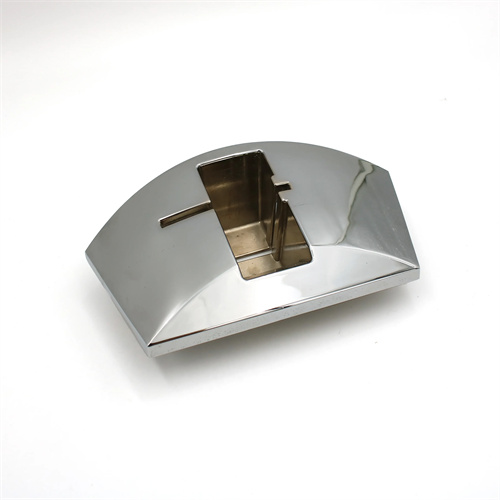

The basic structure of a die-casting machine is the core guarantee for achieving high-pressure molding of molten metal. It consists of multiple systems working together, each with a specific function, to ensure a stable and efficient die-casting process. The clamping system, a key component of the die-casting machine , is primarily responsible for opening, closing, and locking the mold. Its performance directly affects the dimensional accuracy of the casting and the life of the mold. The clamping system typically consists of a fixed platen, a movable platen, tie rods, and a clamping cylinder (or toggle mechanism). The fixed platen is fixed to the machine frame, while the movable platen is connected to the fixed platen by tie rods, which reciprocate along the tie rods to open and close the mold. During the clamping process, the clamping cylinder (or toggle mechanism) provides a strong clamping force, ensuring a tight fit and resisting the expansion force generated by the molten metal filling. For example , a die-casting machine with a clamping force of 2000kN can withstand a pressure equivalent to 200 tons, ensuring that the mold does not form gaps under high pressure. The modern clamping system is also equipped with a mold adjustment device, which can accurately adjust the position of the movable platen according to the thickness of the mold. The mold adjustment accuracy can reach 0.1mm, meeting the installation requirements of different molds.

The injection system is the actuator of a die-casting machine that forces molten metal into the mold cavity at high speed. It determines the density and quality of the casting and is primarily composed of the injection chamber, injection punch, injection cylinder, and accumulator. The injection chamber serves as a temporary storage container for the molten metal. In cold-chamber die-casting machines, the injection chamber is connected to the mold gate, while in hot-chamber die-casting machines, it is connected to the furnace. Driven by the injection cylinder, the injection punch reciprocates, forcing the molten metal in the injection chamber into the mold cavity at high speed and high pressure. Injection speeds can reach 5-15 m/s, and specific injection pressures can reach 50-150 MPa. The accumulator’s function is to rapidly release energy to maintain stable pressure during the injection process. For example, in aluminum alloy die-casting, the accumulator can release sufficient energy within 0.1 seconds to rapidly accelerate the injection punch and prevent premature solidification of the molten metal during the filling process. The performance parameters of the injection system can be flexibly adjusted through the control system to meet the needs of different alloys and castings. For example, the injection speed needs to be increased when producing thin-walled parts, while the injection pressure ratio needs to be increased when producing thick-walled parts.

The power system provides energy for all movements of the die-casting machine and is the “heart” of its operation. It primarily consists of a hydraulic pump, motor, fuel tank, and valves. The hydraulic pump converts the motor’s mechanical energy into hydraulic energy, which is then transferred via hydraulic oil to various actuator cylinders (such as the clamping cylinder and the injection cylinder) to drive component movement. Modern die-casting machines often utilize variable displacement pump systems, which automatically adjust flow and pressure based on workload. Output power is reduced during non-operating periods, resulting in energy savings and consumption reductions of 20-30% compared to traditional fixed-displacement pumps. The fuel tank not only stores hydraulic oil but also dissipates heat and precipitates impurities. Its capacity is typically 3-5 times the hydraulic pump’s minute flow rate, ensuring that the hydraulic oil temperature remains between 30-55°C to prevent wear on hydraulic components caused by excessive oil temperatures. The stability of the power system is crucial. A die-casting plant experienced a power outage due to a hydraulic pump failure, resulting in solidification of the molten metal in the mold cavity and direct economic losses exceeding 100,000 yuan. Therefore, the power system must be equipped with comprehensive fault monitoring and alarm devices.

The control system is the “brain” of the die-casting machine, responsible for coordinating the operations of various systems and achieving automated production. It primarily consists of a PLC (Programmable Logic Controller), touch screen, sensors, and actuators. The PLC receives sensor signals (such as mold position and injection pressure) according to a preset program and issues commands to actuators (such as solenoid valves and servo motors) to control the sequence and parameters of operations such as mold clamping, injection, and mold opening. The touch screen serves as a human-machine interface, allowing the operator to set parameters such as injection speed, clamping force, and hold time with an accuracy of up to 0.01 second (for time parameters) or 0.1 MPa (for pressure parameters). Modern die-casting machine control systems also feature data storage and analysis capabilities, recording production data for each die run (such as shot curves and clamping force variations) to facilitate quality traceability and process optimization. The die-casting machine control system at an automotive parts manufacturer, through historical data analysis, identified a correlation between injection speed fluctuations and casting porosity. By adjusting the injection parameters, the control system increased the casting yield by 8%. In addition, the control system also supports remote monitoring and diagnosis. Manufacturers can monitor the operating status of equipment in real time through the Internet, troubleshoot in a timely manner, and reduce downtime.

While auxiliary systems don’t directly participate in the formation of liquid metal, they play a vital role in the proper operation of the die-casting machine and improving casting quality. These systems primarily include lubrication, cooling, and safety systems. The lubrication system uses an oil pump to deliver lubricating oil to moving components, such as tie rods and guide rails, reducing friction and wear and extending component life. The lubrication interval can be set based on workload, typically every 10-30 minutes. The cooling system uses cooling water to remove heat generated by the equipment’s operation. These systems include mold cooling and hydraulic oil cooling. Mold cooling controls the solidification rate of the casting and reduces internal stress. For example, in aluminum alloy die-casting, by adjusting the mold cooling water flow, casting deformation can be controlled to within 0.1 mm/m. Safety systems include infrared hand guards, emergency stop buttons, and safety gates. If the operator enters the danger zone, the infrared hand guards immediately signal the machine to stop, preventing accidents. The degree of perfection of the auxiliary system directly affects the reliability and safety of the die-casting machine. A die-casting plant suffered a cooling system failure, which led to excessive mold temperature and cracks in the castings, resulting in batch scrapping. Therefore, the daily maintenance of the auxiliary system cannot be ignored.