Classification of die casting machines

As the core equipment in die-casting production, die-casting machines can be divided into multiple types based on their structural form, clamping force, and operating principle. Each type has its own unique application scenarios and technical characteristics. Choosing the right type of die-casting machine is key to ensuring casting quality and improving production efficiency. Currently, the commonly used industrial classification methods for die-casting machines include classification by clamping mechanism type, injection method, and clamping force. These classification methods reflect the performance characteristics of die-casting machines from different perspectives and provide a clear reference framework for production selection.

Based on the type of clamping mechanism, die-casting machines can be divided into two categories: clamping frame die-casting machines and fully hydraulic die-casting machines. Clamping frame die-casting machines (also known as toggle-type die-casting machines) use a toggle-link mechanism to achieve clamping. The clamping force is mechanically amplified, resulting in fast clamping speed and high clamping precision, with a clamping force repeatability of ±1%. During the clamping process, when the mold closes to a certain position, the toggle-link straightens to form a rigid support, effectively resisting the expanding mold force during injection. This makes it suitable for the production of small and medium-sized precision castings (such as mobile phone cases and connectors). Fully hydraulic die-casting machines, on the other hand, utilize hydraulic cylinders to directly drive the clamping force. They offer a wide clamping force adjustment range (from 500kN to 50,000kN) and stepless speed regulation, making them suitable for the production of large, complex castings (such as automotive engine blocks). They also offer greater mold adaptability, particularly for molds with complex core-pulling structures.

Die-casting machines can be categorized by their injection method, either hot-chamber or cold-chamber, depending on how the injection chamber is connected to the furnace. The injection chamber of a hot-chamber die-casting machine is immersed in molten metal, drawing liquid directly from the furnace and injecting it. This results in extremely high production efficiency (300-500 die-casting cycles per hour) and is suitable for die-casting low-melting-point alloys (such as zinc and lead alloys). The typical workflow is: injection punch rises → draws liquid → injection punch descends → injection → mold opening and removal. This results in a short cycle time, minimal oxidation of the molten metal, and excellent casting surface quality. It is widely used in mass production applications such as toys and electronic components. A cold-chamber die-casting machine has its injection chamber separated from the furnace, and molten metal is manually or mechanically ladled into the chamber. This makes it suitable for die-casting high-melting-point alloys (such as aluminum, copper, and magnesium alloys). According to the placement direction of the injection chamber, cold chamber die-casting machines can be divided into horizontal and vertical types. Among them, the horizontal cold chamber die-casting machine has become the mainstream equipment for aluminum alloy die-casting due to its good injection stability and high production efficiency (200-300 times per hour).

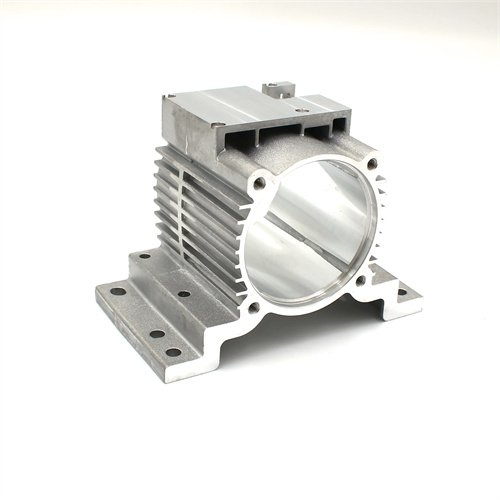

Die-casting machines can be categorized by clamping force: small, medium, large, and extra-large. This classification directly correlates to the maximum size and weight of the castings they can produce. Small die-casting machines typically have a clamping force below 1000kN and are primarily used to produce small parts weighing less than 100g (such as zipper pulls and small hardware). Medium-sized die-casting machines, with clamping forces between 1000-4000kN, are suitable for producing medium-sized castings weighing 100g-1kg (such as automotive door handles and motor end caps). Large die-casting machines, with clamping forces between 4000-10,000kN, can produce castings weighing 1-10kg (such as transmission housings and engine cylinder heads). Extra-large die-casting machines, with clamping forces exceeding 10,000kN and even exceeding 60,000kN (such as the Giga Press die-casting machine used by Tesla), can form large structural parts weighing over 50kg in one piece (such as automotive chassis frames), significantly reducing the number of parts and assembly steps.

With the advancement of die-casting technology, new specialized die-casting machines have emerged, further enriching the die-casting machine classification system. Vacuum die-casting machines significantly reduce porosity in castings by evacuating the mold cavity before injection (to a vacuum level of less than 50 mbar), making them suitable for producing parts requiring high airtightness (such as hydraulic valve bodies). Semi-solid die-casting machines utilize the thixotropic properties of semi-solid metal slurries for die-casting, lowering molding temperatures and minimizing mold wear. They are particularly suitable for the precision molding of high-melting-point alloys. Servo-motor-driven electric die-casting machines, with their precise control of injection speed and pressure through a servo system, consume over 30% less energy than traditional hydraulic die-casting machines. They also offer low noise levels and fast response times, representing the trend toward greener and more intelligent die-casting machines. The emergence of these new die-casting machines has enabled die-casting technology to meet the personalized needs of a wider range of sectors, driving technological advancements in the die-casting industry.