When opening the mold, try to keep the die casting in the movable mold

An important principle in die-casting mold design is to keep the die-casting as much as possible in the movable mold when the mold is opened. This design can simplify the demolding process, improve production efficiency, and reduce the risk of damage to the die-casting during the demolding process. The movable mold is usually equipped with an ejection mechanism that can smoothly eject the die-casting from the cavity after the mold is opened. However, if the die-casting is left in the fixed mold, since the fixed mold side is usually not equipped with an ejection mechanism, it may cause the die-casting to be difficult to remove, and even cause problems such as mold jamming and casting deformation. Therefore, in the mold design, it is necessary to ensure that the die-casting can be reliably retained in the movable mold when the mold is opened by taking measures such as reasonably setting the cavity position, selecting the appropriate demolding slope, and increasing the clamping force on the movable mold side.

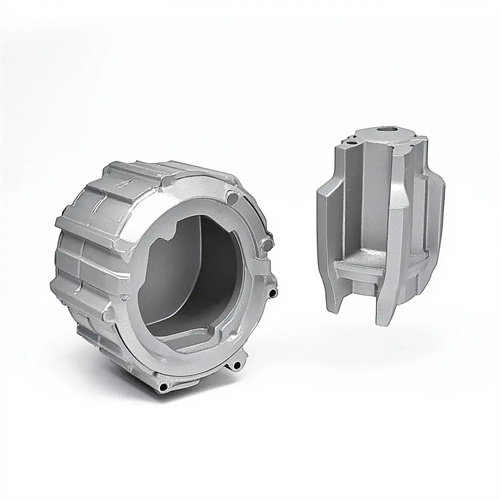

The distribution of the mold cavity on the movable mold and the fixed mold is the basis for determining the direction in which the die casting will be retained in the mold. Generally speaking, the main mold cavity of the die casting should be set on the movable mold side, so that the contact area between the die casting and the movable mold is larger than the contact area with the fixed mold, thereby utilizing the clamping force generated by the cooling and shrinkage of the molten metal to retain the die casting in the movable mold. For example, for die castings with a deep cavity structure, the deep cavity portion should be designed on the movable mold side to increase the contact area and clamping force between the die casting and the movable mold cavity, while reducing the contact area with the fixed mold and reducing the possibility of the die casting being retained in the fixed mold. In addition, by setting fine lines or bumps on the surface of the movable mold cavity, the surface friction can be increased, further enhancing the clamping effect of the movable mold on the die casting.

The reasonable setting of the draft angle also has an important impact on the retention of the die-casting in the movable mold. The draft angle refers to the angle between the side wall of the cavity and the mold opening direction. Its size needs to be determined according to the material, shape and surface roughness of the die-casting. For the side wall of the cavity on the movable mold side, a smaller draft angle should be set, generally 0.5° – 1°, to increase the clamping force between the die-casting and the movable mold; while the side wall of the cavity on the fixed mold side should be set with a larger draft angle, generally 1° – 2°, to facilitate the smooth separation of the die-casting from the fixed mold when the mold is opened. For cavities with a larger height, a gradual draft angle is also required, that is, the bottom slope is smaller and the top slope is larger, which not only ensures sufficient clamping force but also reduces resistance during demolding.

The ejection mechanism set on the movable mold side ensures the smooth demolding of the die-casting after it remains in the movable mold. The ejection mechanism usually includes ejector pins, ejector plates, ejector tubes and other components, and their layout should be evenly distributed on the stress-bearing parts of the die-casting to avoid deformation or damage to the die-casting due to uneven ejection force. When designing the ejection mechanism, it is necessary to ensure that the ejection point is located at the rigid part of the die-casting, such as the thicker wall or the position of the reinforcing rib. At the same time, the stroke of the ejection mechanism should be sufficient to ensure that the die-casting can be completely separated from the movable mold cavity. In addition, the action of the ejection mechanism must be coordinated with the mold opening process. The ejection should be started after the mold is opened to a certain stroke to avoid premature ejection causing interference between the die-casting and the fixed mold.

The exhaust effect of the mold will also affect the mold retention of the die-casting when the mold is opened. If the exhaust of the cavity on the movable mold side is not smooth, it will cause residual gas in the cavity during the die-casting process. These gases may generate reverse pressure when the mold is opened, pushing the die-casting to the side of the fixed mold, affecting the die-casting staying in the movable mold. Therefore, it is necessary to set reasonable exhaust grooves at the parting surface of the movable mold, the depth of the cavity, and other parts to ensure that the gas in the cavity can be discharged smoothly and reduce the interference of the gas on the mold retention direction of the die-casting. The depth and width of the exhaust groove should be designed according to the material of the die-casting. The general depth is 0.02mm – 0.05mm and the width is 5mm – 10mm, which can not only ensure the exhaust effect but also prevent the overflow of molten metal.

Finally, the structural design of the die-casting must also match the mold retention requirements. During the product design stage, structures that are prone to generating clamping forces, such as deep cavities and bosses, should be avoided on the fixed mold side as much as possible to reduce the possibility of the die-casting remaining in the fixed mold. For structures that must be set on the fixed mold side, the clamping force can be reduced by increasing the demoulding slope, setting a release agent groove, etc. At the same time, the surface quality of the die-casting will also affect the mold retention effect. An overly smooth surface may reduce the friction with the movable mold, which is not conducive to the die-casting remaining in the movable mold. Therefore, during the design, the contact surface on the movable mold side can be appropriately roughened as needed. By comprehensively applying the above measures, it can be effectively ensured that the die-casting remains in the movable mold when the mold is opened, creating favorable conditions for the subsequent demoulding and removal process.