Design of the Sprue for the Die-casting Mould with Horizontal Cold Chamber

The sprue of a horizontal cold-chamber die-casting mold is a crucial channel connecting the pressure chamber and the runner. Its design quality directly impacts the filling efficiency of the molten metal, the effectiveness of pressure transmission, and the overall quality of the casting. Compared to hot-chamber die-casting molds, the sprue of a horizontal cold-chamber die-casting mold differs significantly in structure, dimensional parameters, and coordination with the pressure chamber. Therefore, a targeted design must be tailored to the operating characteristics of the horizontal die-casting machine and the flow properties of the molten metal. The sprue design must not only ensure smooth and rapid entry of the molten metal into the mold cavity but also consider issues such as venting, oxidation prevention, and condensate release. It is a comprehensive design task.

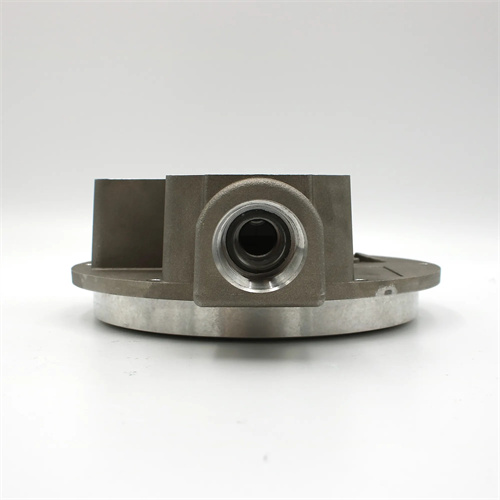

The sprue structure must be compatible with the pressure chamber structure of a horizontal cold-chamber die-casting machine. Common types include stepped, tapered, and combined. A stepped sprue consists of multiple cylindrical segments of varying diameters, with the diameter gradually decreasing from the chamber outlet toward the runner. This structure effectively reduces pressure loss in the molten metal and facilitates demolding, making it suitable for die-casting of medium- to large-sized castings. A tapered sprue utilizes a single taper design, typically ranging from 1° to 3°. This allows the molten metal to gradually accelerate during flow, resulting in more uniform pressure distribution and is suitable for small to medium-sized, thin-walled castings. A combined sprue combines the advantages of both stepped and tapered designs. The stepped front section reduces initial resistance, while the tapered rear section accelerates the molten metal. This makes it suitable for complex castings requiring high filling speeds and pressures. When selecting a structural form, the size and shape of the casting, as well as the die-casting machine’s injection capacity, should be considered to ensure the sprue works harmoniously with the overall gating system.

The design of the sprue’s dimensional parameters, primarily including diameter, length, and taper, is crucial for ensuring its performance. The sprue’s inlet diameter should match the chamber’s outlet diameter, typically 1mm-2mm larger, to prevent eddy currents and pressure loss in the molten metal at the inlet. For a chamber diameter of 40mm-100mm, the sprue’s inlet diameter can be set between 41mm-102mm. The sprue’s length should be kept as short as possible, generally within 150mm, to minimize heat loss and pressure drop during molten metal flow. If mold structural limitations prevent shortening the length, the sprue’s diameter should be appropriately increased to compensate for pressure loss. The taper should be determined based on the molten metal’s fluidity. For aluminum alloys with good fluidity, a taper of 1°-2° is acceptable; for copper alloys with less fluidity, a taper of 2°-3° is recommended to ensure smooth molten metal flow and fill the mold cavity.

The design of the sprue and pressure chamber must balance sealing performance and positioning accuracy to prevent molten metal leakage and mold misalignment during operation. A positioning boss or guide cone should be installed at the inlet of the sprue, with a clearance between it and the pressure chamber outlet controlled between 0.05mm and 0.1mm. This ensures accurate positioning while preventing wear caused by an overly tight fit. The flatness error of the mating surfaces should not exceed 0.01mm/100mm, and the surface roughness should be controlled below Ra0.8μm to ensure a tight fit and reduce the risk of molten metal leakage. For high-pressure die-casting processes (injection pressure >100MPa), a high-temperature-resistant sealing ring should be installed at the inlet of the sprue to further enhance the sealing effect. Furthermore, the coaxiality error between the sprue and pressure chamber must be controlled within 0.1mm. This can be achieved by using positioning mechanisms such as guide pins and guide sleeves to prevent turbulent molten metal flow and mold wear caused by coaxial deviation.

The material selection and heat treatment process for the sprue must meet the requirements for high strength, high wear resistance, and thermal fatigue resistance. Commonly used materials include H13 hot work die steel and 3Cr2W8V. These materials have excellent high-temperature strength and toughness, capable of withstanding high-speed molten metal erosion and repeated thermal shock. The material’s chemical composition must be strictly controlled, with a carbon content between 0.32% and 0.45% and a chromium content between 11% and 13% to ensure sufficient hardness and wear resistance. The heat treatment process uses a “quenching + tempering” process, with a quenching temperature of 1020°C to 1050°C and a tempering temperature of 580°C to 620°C, achieving a hardness of 45-50 HRC. This ensures wear resistance while avoiding brittle fracture caused by excessively hard materials. For molds that produce high-melting-point alloys for a long time, the sprue surface can be nitrided to form a nitride layer with a thickness of 0.03mm-0.05mm, and the hardness is increased to above 60HRC, which significantly improves its wear resistance and service life.

The design of the sprue’s exhaust and cooling systems is also crucial. A venting groove with a width of 5mm-10mm and a depth of 0.02mm-0.05mm should be installed at the junction of the sprue and runner. This ensures that gases generated during the molten metal flow can be discharged smoothly, preventing defects such as porosity in the casting. The cooling system design should be determined based on the sprue’s dimensions and operating temperature. Cooling channels can be located around the sprue, 15mm-25mm from the sprue’s outer wall. Circular channels with a diameter of 8mm-12mm should be used, with a flow rate of 1m/s-2m/s to ensure uniform cooling. The cooling water temperature should be controlled between 50°C and 80°C, with a minimum temperature difference from the mold’s operating temperature to avoid mold cracking due to thermal shock. Proper exhaust and cooling design ensures a stable sprue temperature and smooth molten metal flow during operation, thereby improving casting quality and production efficiency.