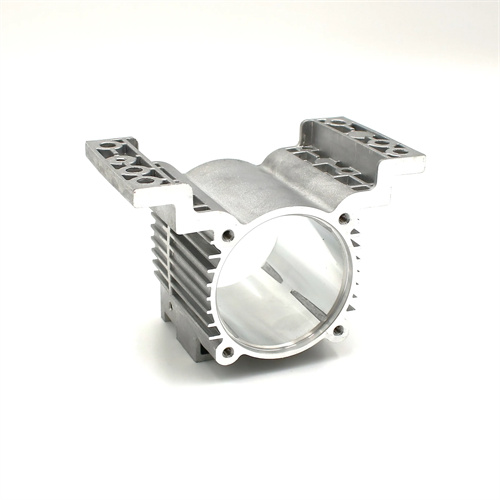

Connection between runner and ingode of die casting mold

The connection between the runner and ingode in a die-casting mold is a critical transition in the gating system, and its design quality directly impacts the flow of molten metal, the efficiency of pressure transmission, and the quality of the casting. A reasonable connection method can guide the molten metal smoothly from the runner into the ingode, reducing turbulence, eddy currents, and pressure loss, while preventing impurities and gas from entering the mold cavity. This is a key factor in ensuring the density and mechanical properties of die-casting parts. The connection between the runner and ingode requires consideration of multiple dimensions, including transition form, angle, cross-sectional changes, and positional relationships. Through refined design, efficient transfer of molten metal is achieved.

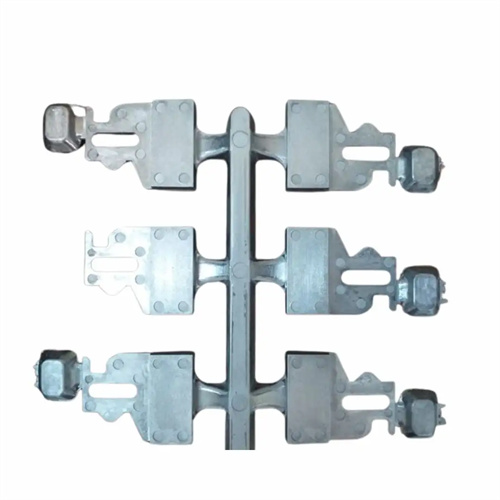

The choice of transition type is fundamental to joint design. Common transition types include right-angle transition, rounded transition, and sloped transition. A right-angle transition is the simplest form, connecting the runner and ingode directly and perpendicularly. While simple to machine, it can easily generate eddy currents and pressure loss, making it suitable only for simple castings with low quality requirements. A rounded transition smoothly connects the runner and ingode through an arc with a radius of 3mm-8mm. This effectively reduces flow resistance and allows the molten metal to smoothly divert along the arc. It is the most widely used transition type and is suitable for most aluminum and zinc alloy castings. A sloped transition uses a 15°-45° bevel to achieve the connection. The molten metal gradually enters the ingode along the slope, minimizing pressure loss and maximizing flow. It is suitable for thin-walled, complex, and high-precision castings, but it is more difficult to machine and requires CNC milling to ensure the bevel accuracy. In actual design, either a rounded or sloped transition should be preferred. The specific form should be determined based on the casting quality requirements and machining capabilities to avoid casting defects caused by a right-angle transition.

The connection angle must be designed to match the direction of molten metal flow to ensure smooth diversion and minimize energy loss. The angle between the runner and the ingode is generally controlled between 30° and 90°, with the specific angle determined based on the ingode’s location and cavity filling requirements. When the ingode is located on the side of the runner, an angle of 45° to 60° maintains a high molten metal flow rate during diversion, making it suitable for thin-walled castings that require rapid filling. When the ingode is located at the end of the runner, a 90° angle can be used, utilizing the molten metal pressure within the runner to directly push the ingode through the runner, making it suitable for pressure transfer in thick-walled castings. The connection angle must also be coordinated with the cross-sectional dimensions of the runner. For example, large runners (width > 15mm) use a larger angle (60° to 90°), while small runners (width < 10mm) use a smaller angle (30° to 45°) to ensure stable molten metal flow during diversion.

Smooth cross-sectional changes are key to minimizing pressure loss. The junction between the runner and ingates should avoid sudden dimensional changes and instead adopt a gradual transition. The ingate entrance width is generally 50%-80% of the runner width. For example, if the runner width is 10mm, the ingate entrance width can be set to 5mm-8mm. A 1mm-2mm gradient is used to achieve this dimensional transition and avoid turbulence caused by sudden cross-sectional changes. For thickness changes, the ingate thickness should be slightly less than the runner height (generally 70%-90%), and a 0.5mm-1mm ramp should be used to gradually reduce the molten metal as it enters the ingate, enhancing flow stability. The design of cross-sectional changes also needs to consider the solidification characteristics of the molten metal. For alloys with faster solidification rates (such as magnesium alloys), the gradient should be shortened (1mm-2mm) to prevent premature solidification in the transition zone. For alloys with better fluidity (such as aluminum alloys), the gradient can be extended (2mm-4mm) to further minimize pressure loss.

The choice of connection position needs to be combined with the structural characteristics of the cavity to ensure that the molten metal can be evenly filled after entering the cavity. The connection point between the ingrown and the runner should avoid the bends or diversions of the runner. These locations are prone to eddy currents and pressure fluctuations, resulting in unstable state of the molten metal entering the ingrown. The connection point should be set in the straight section of the runner, and the distance from the bend should be no less than 3 times the width of the runner (for example, for a runner with a width of 10mm, the connection point needs to be more than 30mm away from the bend) to ensure that the molten metal forms a stable laminar flow before entering the ingrown. For cavities with multiple ingrowns, the connection points of each ingrown and the runner should be evenly distributed along the runner, with a spacing of no less than 20mm to avoid mutual interference of the molten metal in the runner and ensure uniform feeding of each ingrown.

Furthermore, the strength and wear resistance of the joints must be considered. This area, where the molten metal flows at high speed, is susceptible to erosion and wear. High-strength materials (such as H13 steel) must be used and hardened (to a hardness of 50-55 HRC) to extend the life of the mold. The surface roughness of the joints should be controlled below Ra0.8μm to reduce frictional resistance to molten metal flow and facilitate demolding and cleaning. For large molds or high-pressure die-casting processes, reinforcing ribs can be added to the joints to enhance structural rigidity and prevent deformation under high pressure. By comprehensively considering these factors, the design of the runner-ingate connection ensures a smooth transition of molten metal, reliably ensuring the production of high-quality castings.