Gate design in die casting mold

The design of die-casting mold ingates is one of the most critical aspects of gating system design. As the final passage for molten metal to enter the mold cavity, the size, shape, position, and number of ingates directly impact the filling speed, pressure transmission, temperature distribution, and the final quality of the casting. A well-designed ingate guides the molten metal to fill the mold cavity smoothly and evenly, minimizing defects such as eddy currents, air entrapment, and oxidation, while ensuring the casting possesses excellent density and mechanical properties. Ingate design requires careful consideration of factors such as the casting’s structural characteristics, material properties, and die-casting process parameters, leading to detailed design and calculation.

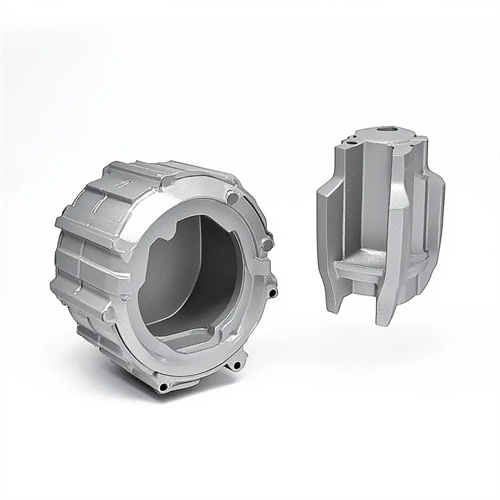

The location of the ingates is the primary consideration in design. Whether the location is reasonable directly determines the flow path of the molten metal in the mold cavity and the filling effect. Generally speaking, the ingates should be set in the thick-walled part of the casting or in the area where the molten metal is easily diffused. This can utilize the heat capacity of the thick-walled part to slow the solidification rate of the molten metal, ensure that the pressure can be effectively transmitted to all parts of the casting, and reduce defects such as shrinkage cavities and shrinkage. The ingates should avoid directly impacting the mold cavity wall or slender core to prevent wear of the mold cavity wall or deformation of the core. For ingates that must be set in thin-walled parts, the molten metal can be smoothly introduced into the mold cavity by setting a guide groove or changing the direction of the gate. In addition, the location of the ingates should also avoid important functional surfaces or processing surfaces of the casting to reduce the workload of cleaning the gate marks and improve the surface quality of the casting.

The design of the ingate dimensions is crucial for ensuring efficient filling and pressure transfer. These dimensions primarily include width, thickness, and length. The thickness of the ingate is one of the most important parameters and is typically determined based on the wall thickness of the casting, generally ranging from 1/3 to 1/2 the thickness of the thinnest part. For aluminum alloy castings, the thickness typically ranges from 0.5mm to 3mm. An ingate that is too thin increases flow resistance, slows filling, and can easily lead to underfilling. An ingate that is too thick increases subsequent cleaning difficulties and may cause shrinkage cavities at the gate. The width of the ingate should be determined based on the required flow rate to ensure that the molten metal fills the mold cavity within the specified time. For large castings or designs with multiple ingates, the width of each ingate should be adjusted based on flow distribution requirements to ensure synchronized filling. The ingate length should be as short as possible, typically 1mm to 3mm, to minimize pressure loss and solidification time of the molten metal at the gate, thereby improving pressure transfer efficiency.

The shape design of the ingate will also affect the flow characteristics of the molten metal. Common ingate shapes include rectangular, trapezoidal, circular, and fan-shaped. The rectangular ingate is the most widely used. It is easy to process and has stable flow control, making it suitable for most castings. The trapezoidal ingate has a trapezoidal cross-section, which facilitates the rapid diffusion of the molten metal after entering the cavity. It is suitable for thin-walled, large-area castings. The circular ingate has low flow resistance and good pressure transmission effect, but it is more difficult to process and is suitable for castings with high pressure transmission requirements. The fan-shaped ingate allows the molten metal to enter the cavity with a wider front, reducing turbulence during the flow process and is suitable for flat castings. The shape of the ingate should be selected in combination with the structure and filling requirements of the casting. For example, for flat castings that require uniform filling, a fan-shaped ingate is a better choice. For thick-walled castings that require concentrated feeding, circular or rectangular ingates can be used.

The number of ingates should be designed based on the complexity and size of the casting. For small, simple castings, a single ingate is usually sufficient for filling. However, for large, complex castings or molds with multiple independent cavities, multiple ingates are required to enable multi-point feeding, ensuring that all parts are filled simultaneously and reducing temperature unevenness and stress concentration caused by differences in filling time. The layout of multiple ingates should be symmetrical and balanced to avoid the impact of molten metal within the cavity, thereby preventing air entrapment and oxidation. Furthermore, the size of each ingate should be adjusted according to the size of the filling area it is responsible for to ensure proper flow distribution. For example, for symmetrical castings, symmetrical ingates of the same size can be used. For asymmetrical castings, the ingates should be sized according to the volume and flow resistance of each area to ensure synchronous filling.

The ingate design must also be compatible with die-casting process parameters such as injection speed, shot pressure, and mold temperature. The size and shape of the ingate should accommodate the selected injection speed, ensuring that the molten metal has the appropriate kinetic energy upon entering the mold cavity, allowing it to fill the cavity without generating excessive turbulence. Higher injection speeds require larger ingate sizes to prevent splashing and air entrainment during the flow of the molten metal; lower injection speeds, on the other hand, allow for smaller ingate sizes to ensure adequate pressure transfer. Furthermore, the influence of mold temperature must be considered when designing the ingate. For lower mold temperatures, the ingate size can be increased to accelerate filling and prevent premature solidification of the molten metal. For higher mold temperatures, the ingate size can be reduced to control filling speed and avoid defects such as flow marks. By optimally matching the ingate design with the process parameters, the advantages of the die-casting process can be fully utilized, improving casting quality and production efficiency.