Feeding and positioning of die casting inserts

The feeding and positioning of die-casting inserts are critical to ensuring die-casting quality. As a component of the casting, the insert must be precisely secured within the mold cavity during the die-casting process, forming a strong bond with the molten metal. The feeding method must be selected based on the insert’s shape, size, and production batch size. Positioning must ensure that the insert does not shift or deform under the die-casting pressure. The rationality of both design directly impacts the dimensional accuracy and mechanical properties of the casting.

The manual feeding method is suitable for small-batch production or large inserts. The operator places the insert into the mold’s positioning device before closing the mold. It is easy to operate but inefficient. Inserts for manual feeding need to be designed with structures that are easy to grasp, such as bosses, holes, or grooves, to prevent them from slipping or being damaged during grasping. The positioning device must have a clear guide structure, such as a guide cone or positioning column, to guide the insert into the correct position quickly. The guide cone has an inclination of 15°-30° and a height of 5-10mm to ensure that the insert can be smoothly introduced. The positioning accuracy of manual feeding mainly depends on the operator’s skills, so the positioning device must have an error-proofing function, such as asymmetric positioning holes or guide columns, to prevent the insert from being placed upside down or off-center. The positioning error must be controlled within 0.1mm.

The semi-automatic feeding method combines manual placement and mechanically assisted positioning, and is suitable for medium-volume production. The inserts are transported to the material removal position via a vibrating plate or feed track and placed in the mold by the operator. The amplitude and frequency of the vibrating plate need to be adjusted according to the weight of the inserts to ensure that the inserts are arranged in order. The width of the feed track is 0.5-1mm larger than the maximum size of the insert to avoid material jamming. A blocking mechanism must be set at the material removal position to separate the inserts individually for easy grasping. The blocking mechanism can use a cylinder-driven baffle with a response time of less than 0.5s. The positioning accuracy of semi-automatic feeding is higher than that of the manual method. The locating pins on the mold are matched with the holes of the inserts, with a matching clearance of 0.02-0.04mm. It is suitable for inserts with higher dimensional accuracy requirements, such as bearing inserts for motor end covers.

The fully automatic feeding method is suitable for large-scale production. Robots or specialized robotic arms handle the gripping, conveying, and placement of inserts, enabling unmanned operation. The fully automatic feeding system includes a feeder, conveyor tracks, positioning detection, and a robotic gripper. The feeder utilizes a hopper or coil feeder to continuously supply inserts. The conveyor tracks utilize a belt or chain drive at a speed of 5-10 m/min, ensuring a feeding rhythm that matches the die-casting machine. The robot’s repeatability is ≤ 0.05 mm, and the gripping force is adjustable to prevent damage to the inserts. The gripper is customizable to the insert shape and uses pneumatic or electric drives, with a changeover time of less than 5 minutes. The fully automatic feeding method is highly efficient, processing 500-1000 inserts per hour. It is suitable for small, highly standardized inserts, such as copper inserts in electrical connectors.

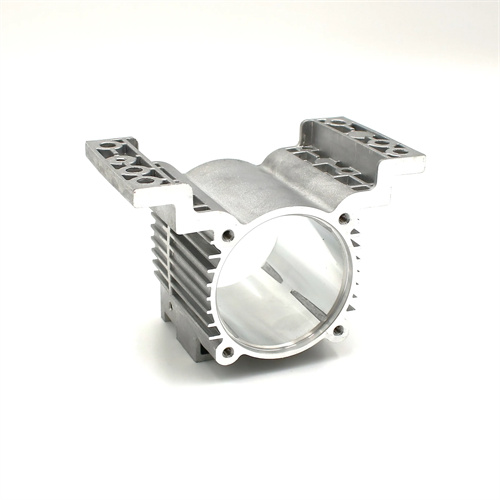

The insert’s positioning structure design must adhere to the “three-sided positioning” principle, requiring the insert to be constrained in at least three directions to prevent displacement during die-casting. Common positioning methods include pin positioning, step positioning, and cavity positioning. Pin positioning utilizes one or two positioning pins that mate with the insert’s holes. This method is suitable for inserts with holes, with the pin diameter 0.02-0.04mm smaller than the hole diameter. Step positioning utilizes a stepped surface on the mold to limit the insert’s axial displacement. The step height is 0.1-0.2mm greater than the insert’s thickness, ensuring a close fit on the insert’s bottom surface. Cavity positioning precisely aligns the insert’s shape with the mold cavity, with a clearance of 0.03-0.05mm. This method is suitable for non-porous, irregular-shaped inserts. The positioning structure must ensure uniform force distribution during die-casting to avoid deformation caused by excessive local stress. For example, a long, rectangular insert requires at least three positioning points, located at both ends and in the middle.

The stability of insert positioning needs to be guaranteed by preload and anti-deformation design. For thin-walled inserts, elastic positioning devices such as spring pressure plates or rubber pads are required, with a preload of 5-10N to both secure the insert and avoid crushing. The material of the positioning device needs to be high temperature resistant, using quenched 45 steel or copper alloy to prevent high-temperature molten metal from affecting the positioning accuracy. An overflow trough with a width of 3-5mm and a depth of 0.5-1mm needs to be set at the part where the insert contacts the molten metal to prevent the molten metal from penetrating the positioning gap and making it difficult to remove the insert. In addition, the positioning device needs to be easy to clean to avoid residual metal debris affecting the positioning accuracy. A slag discharge hole with a diameter of 1-2mm can be opened at the bottom of the positioning hole to discharge impurities in time. Through reasonable feeding and positioning design, the pass rate of insert die-casting can be increased to more than 99%, significantly reducing production costs.