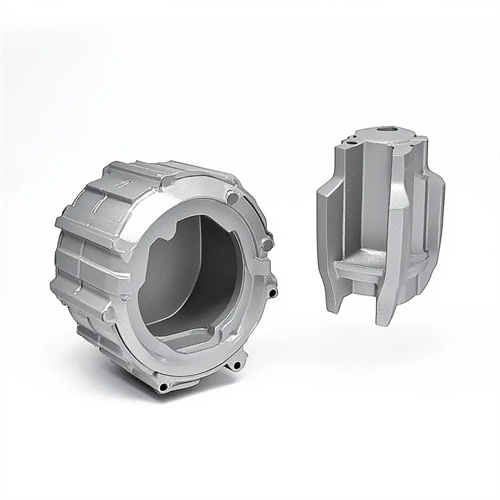

Structure of the guide part of the die-casting mold slider

The guide of a die-casting mold’s slider is a critical structure for ensuring precise movement. Its primary function is to constrain the slider’s trajectory, reduce wobbling and offset during core pulling, and ensure the core can be smoothly extracted and reset along the preset path. The structural design of the guide must balance guiding accuracy, load-bearing capacity, and wear resistance. Depending on the slider’s size, core-pulling force, and motion characteristics, it can be categorized into various types: T-slot guides, dovetail groove guides, rail guides, and combined guides. Guides of different structures vary in processing difficulty, cost, and applicable scenarios, and must be selected based on the specific mold requirements.

The T-slot guide is the most widely used structural form. It consists of a T-shaped boss on the bottom of the slider that mates with a T-shaped groove on the template. It is suitable for medium core pulling forces (50-200kN) and small and medium-sized sliders. Its advantages are simple processing, being formed by milling, and the clearance can be easily controlled to 0.02-0.05mm. However, its disadvantages are relatively low guiding accuracy, and the T-slot side is prone to wear after long-term use, resulting in increased clearance. The width of the T-slot is typically 1/3-1/2 of the slider width, and the depth is 1/2 of the width. For example, for a 100mm wide slider, the T-slot width is 40mm and the depth is 20mm. To improve wear resistance, the T-slot surface can be hardened (hardness 40-45HRC) or inlaid with a wear-resistant alloy strip (such as ZCuAl10Fe3) with a thickness of 3-5mm, secured with countersunk screws to ensure flushness with the groove surface.

Dovetail guides consist of a dovetail-shaped boss on the slider and a dovetail-shaped groove on the mold plate. They offer high guiding precision and are suitable for demanding precision die-casting molds. Core-pulling forces generally do not exceed 150kN. The dovetail groove typically has an angle of 55° or 60°, a large contact area, and excellent positioning stability. The clearance can be controlled to 0.01-0.03mm, effectively reducing lateral offset during slider movement. Its machining is more difficult than a T-slot, requiring milling and grinding to ensure angular accuracy. The dovetail groove has a depth of 5-10mm, and the bottom width is determined by the slider size, generally 1/4-1/3 of the slider width. Dovetail guides are suitable for castings requiring high molding precision, such as precision components for automotive engines. They ensure a positional error of ≤0.02mm during core extraction, preventing dimensional deviations in the casting.

Guide rail-type guides utilize independent guide rails in conjunction with sliders, making them suitable for applications requiring large sliders and high core-pulling forces (over 200kN), such as die-cast molds for large engineering machinery parts. The guide rails have a rectangular or trapezoidal cross-section and are bolted to the mold plate. The bottom of the slider features a matching groove with a clearance of 0.03-0.06mm. Guide rail-type guides offer a strong load-bearing capacity, and the guide length can be extended as needed, typically 3-4 times the slider stroke, ensuring the slider remains stable during long-distance movement. The guide rails are made of 40Cr steel, with a hardness of 45-50HRC after quenching and a surface roughness of Ra0.8μm or less. Wear-resistant copper plates can be embedded in the slider grooves to reduce the coefficient of friction. The advantages of guide rail-type guides include easy installation and adjustment. The guide rails can be replaced individually after wear, eliminating the need for template repair and resulting in low maintenance costs.

Combined guides combine the advantages of various guide types and are suitable for sliders with complex core-pulling trajectories, such as composite sliders that need to achieve both horizontal and vertical movement. Common combinations include “T-slots + guide rails” or “dovetail grooves + guide posts.” The T-slots or dovetail grooves ensure accuracy in the primary direction of movement, while the guide rails or guide posts constrain displacement in the secondary direction, reducing the risk of interference in composite movements. The mating clearances of combined guides need to be controlled separately, with the main guide clearance being 0.02-0.04mm and the auxiliary guide clearance being 0.03-0.05mm. Adjustments are made through grinding to ensure coordinated movement in all directions. For example, in the die-casting mold for automobile transmission housings, combined guides can achieve micro-angle adjustments of the slider during the core-pulling process, preventing scraping between the core and the inner wall of the casting and improving the surface quality of the casting.

The lubrication and cooling design of the guide slide is crucial to extending its service life. Regardless of the type of guide slide used, lubrication grooves must be provided on the guide slide surface. The lubrication grooves should be distributed in a mesh or spiral pattern, with a depth of 0.5-1mm and a width of 2-3mm. High-temperature grease (temperature resistance ≥200°C) should be regularly added to reduce friction and wear. For molds produced continuously, an automatic lubrication system can be installed to deliver lubricating oil to the guide slide surface via a timed pump to ensure continuous and effective lubrication. The cooling water channel of the guide slide should be located 15-25mm from the guide slide surface, with a diameter of 8-12mm and a water flow rate of 1-2m/s. The temperature of the guide slide surface should be controlled at 50-80°C to avoid thermal deformation that affects the fit accuracy. Through reasonable lubrication and cooling design, the service life of the guide slide can be extended by more than 30%, reducing the frequency of mold maintenance.