Post-processing of die castings

Post-processing of die-castings refers to a series of processing and treatment processes performed after the die-castings are removed from the mold to meet their performance, appearance quality, and assembly requirements. It is an important step in ensuring the final quality of the die-castings. There are many types of post-processing processes, including cleaning, deburring, heat treatment, surface treatment, machining, etc. Different die-castings require different post-processing processes according to their application and quality requirements. For example, aluminum alloy die-castings used in automobile engines usually require multiple post-processing processes such as deburring, cleaning, heat treatment, and surface spraying to ensure their mechanical properties and corrosion resistance; while zinc alloy die-castings used in toys may only require simple cleaning and surface electroplating.

The primary purpose of post-processing is to remove surface defects and impurities from die-cast parts and improve surface quality. During the die-casting process, die-cast parts may retain residual flash, burrs, scale, and oil stains. These defects not only affect the appearance of the die-cast parts but can also interfere with assembly and even affect product performance. Cleaning and deburring processes can remove these surface defects, leaving the die-cast parts smooth and flat. For example, after die-casting, die-cast mobile phone casings will develop tiny burrs on their edges. If left untreated, these burrs not only affect the feel but can also cause scratches. Dedicated deburring equipment (such as vibration grinders and ultrasonic deburring machines) can remove these burrs, resulting in smooth, rounded edges.

Post-processing can improve the internal quality of die-castings and enhance their mechanical properties. Some die-castings may develop internal defects such as porosity and shrinkage during the die-casting process. These defects can reduce the strength and sealing of the die-casting. Impregnation treatments (such as vacuum infiltration) can fill these internal defects and improve the density of the die-casting. For die-castings with higher mechanical performance requirements, heat treatments (such as aging) can also be performed to adjust the alloy’s internal structure and improve properties such as tensile strength and hardness. For example, after T6 heat treatment (solution treatment + artificial aging), the tensile strength of aluminum alloy die-castings can be increased by 20%-30%, and the hardness is significantly improved, meeting the requirements of high-strength parts.

Surface treatment is an important component of die-casting post-processing, primarily aimed at improving the corrosion resistance, wear resistance, and decorative properties of die-castings. Common surface treatment methods include electroplating, spraying, anodizing, and phosphating, with different surface treatment methods being suitable for different alloys and usage environments. For example, zinc alloy die-castings are typically electroplated (e.g., chrome plating, zinc plating) to improve their corrosion resistance and surface gloss. Aluminum alloy die-castings are often anodized to form a dense oxide film, which not only improves corrosion resistance but can also be dyed to various colors for decorative effects. Die-castings intended for outdoor use are typically sprayed (e.g., powder coating, fluorocarbon spraying) to provide excellent weather resistance and decorative properties.

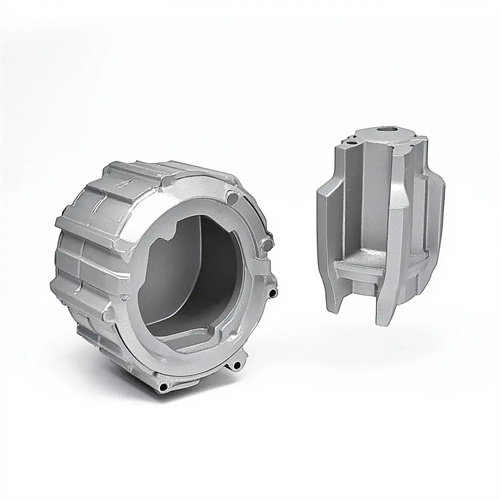

Post-processing also facilitates the assembly and use of die-castings. For die-castings that require assembly, machining (such as drilling, tapping, and milling) may be necessary to produce precise assembly dimensions and mating surfaces to ensure assembly accuracy. For example, automotive transmission housing die-castings require bearing holes, bolt holes, and other components to be machined in specific locations. These holes require high dimensional and positional accuracy, and must undergo precision machining to meet assembly requirements. Furthermore, die-castings with sealing requirements (such as hydraulic components) require sealing testing and sealing treatment to ensure no leakage during use. The rational arrangement and strict control of post-processing procedures can significantly improve the quality and performance of die-castings, extending their service life, and are an indispensable and important step in the die-casting production process.