Analysis of die casting defects

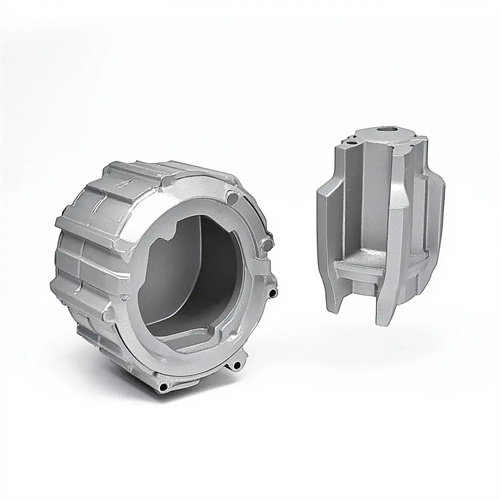

Die-castings are common components in industrial production, and their quality directly impacts product performance and service life. Defects are often a key factor limiting quality. Die-casting defects vary, with common ones including porosity, shrinkage, cracks, cold shuts, and insufficient pouring. Each defect is closely linked to multiple steps in the production process. In-depth analysis of the causes of these defects is fundamental to resolving them and improving product quality.

Porosity is one of the most common defects in die-castings. It manifests as holes of varying sizes inside or on the surface of the casting, often containing gas. The formation of pores is primarily related to the gas content in the molten metal, the exhaust during the die-casting process, and the mold design. During metal smelting, if the molten metal comes into excessive contact with air and moisture, it absorbs large amounts of gases, such as hydrogen and nitrogen. If these gases are not promptly expelled during the die-casting process, pores will form within the casting. In addition, improperly designed vent grooves in the mold, or if the vent grooves are clogged with metal debris, can prevent the gas in the cavity from being discharged smoothly, leading to the formation of pores. Porosity not only reduces the mechanical properties of the casting but can also cause leakage and other problems during subsequent processing or use.

Shrinkage cavities typically appear as irregular holes within a casting, with rough inner walls often resembling dendritic or honeycomb structures. Shrinkage cavities are primarily caused by insufficient shrinkage compensation during the solidification process. After the molten metal is injected into the mold cavity, as it cools and solidifies, the different cooling rates of different parts of the casting cause the first-solidified portion to form a hard shell. As the unsolidified metal inside continues to cool and shrink, if it lacks sufficient molten metal to replenish it, shrinkage cavities will form. Shrinkage cavities often appear in thicker and larger areas of the casting, corners, and near the gate, where cooling rates are relatively slow and poor shrinkage compensation is more likely to occur. Shrinkage cavities can severely affect the strength and density of the casting, causing it to fracture under stress.

Cracks are a serious defect in die-castings, appearing as fracture lines on the surface or within the casting. The distribution and morphology of cracks vary, ranging from linear to reticular. The occurrence of cracks is related to factors such as the casting material, the die-casting process, and the die structure. For example, when the casting contains a large number of impurities or an improper ratio of alloying elements, the material becomes more brittle and is prone to cracking during the die-casting process. Furthermore, excessive injection speeds and mold temperatures that are too low or too high during die-casting can also generate significant stress within the casting, leading to cracks. The presence of cracks can significantly reduce the bearing capacity of the casting and may even result in the casting being scrapped.

Cold shuts and underruns are also common defects in die castings. Cold shuts appear as irregular lines or depressions on the surface of the casting. They occur when different areas of molten metal fail to fully fuse after being injected into the mold, forming separation lines after solidification. Underruns occur when the molten metal fails to completely fill the entire mold cavity, resulting in an incomplete casting shape. The occurrence of these two defects is primarily related to factors such as molten metal fluidity, die casting temperature, injection pressure, and mold runner design. When the molten metal has poor fluidity, the die casting temperature is too low, or the injection pressure is insufficient, the flow rate of the molten metal in the mold cavity slows, making cold shuts and underruns more likely to occur. Furthermore, improper mold runner design, such as one that is too thin, too long, or has excessive bends, can increase flow resistance to the molten metal, leading to these defects. Cold shuts and underruns can affect the appearance quality and performance of castings, requiring effective measures to prevent and address them.