Aluminum Die Casting: Strength-to-Weight Ratio for High-Performance Applications

Aluminum die casting delivers an exceptional strength-to-weight ratio that makes it ideal for high-performance components where both durability and weight reduction are critical. Unlike heavier metals like steel, aluminum inherently offers lower density while maintaining sufficient strength for demanding applications. Through advanced alloy formulations and precise casting processes, we produce die cast parts that achieve tensile strengths exceeding 300 MPa—comparable to some steels—while weighing 30-50% less. This weight reduction directly enhances performance in industries like automotive and aerospace, improving fuel efficiency, acceleration, and maneuverability. High-performance alloys like A380 and ADC12, combined with heat treatment options, further boost mechanical properties, including fatigue resistance essential for components enduring repeated stress cycles. The uniform material structure achieved through die casting eliminates weak points found in welded or assembled components, ensuring consistent strength across the entire part. By balancing strength and lightness, aluminum die casting enables the development of high-performance components that outperform alternatives in both efficiency and durability.

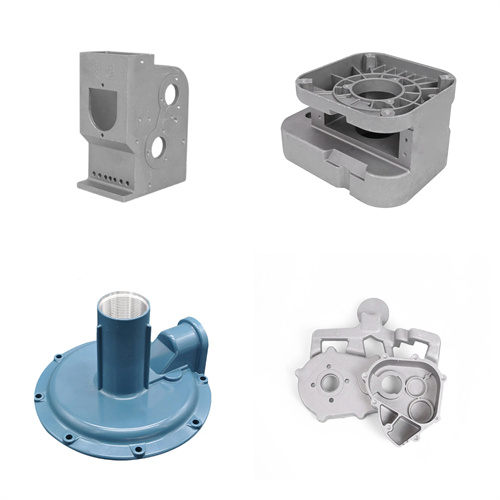

Aluminum Die Casting: Precision and Complexity for Performance-Critical Designs

The ability of aluminum die casting to produce complex, precision components gives it a distinct advantage in high-performance applications requiring intricate geometries. Unlike machining or forging, which struggle with complex internal features or tight tolerances, die casting can replicate detailed mold surfaces with dimensional accuracies of ±0.02mm for critical features. This precision allows us to incorporate performance-enhancing design elements like internal cooling channels, optimized rib patterns, and integrated mounting points that would be difficult or impossible to achieve with other processes. For high-performance components such as engine brackets or transmission housings, this means we can design parts with precisely controlled wall thicknesses to balance weight and strength. The tight tolerances reduce assembly gaps and improve part alignment, enhancing overall system performance. Advanced mold-making techniques, including 3D-printed inserts, enable even more complex geometries, allowing engineers to push the boundaries of performance through innovative design without manufacturing limitations.

Aluminum Die Casting: Production Efficiency for High-Volume Performance Parts

Aluminum die casting offers unmatched production efficiency for manufacturing high-performance components at scale, ensuring consistent quality even in large-volume production runs. Once molds are properly configured, die casting machines can produce hundreds of identical parts per hour with minimal variation—a critical factor for high-performance systems where component consistency directly impacts performance. This efficiency stems from the process’s rapid cycle times (typically 30-90 seconds per part) and minimal post-processing requirements, as die cast parts often meet final specifications right out of the mold. Automated production cells further enhance efficiency by enabling 24/7 operation with reduced labor costs. For industries like automotive racing or industrial machinery, where high volumes of performance-critical parts are needed, this efficiency translates to faster time-to-market and lower per-unit costs without compromising quality. The repeatability of aluminum die casting ensures that every component performs identically, maintaining consistent system performance across production batches.

Aluminum Die Casting: Thermal Conductivity for Heat-Intensive Performance Components

Aluminum die casting’s excellent thermal conductivity makes it superior for high-performance components operating in heat-intensive environments. Aluminum naturally conducts heat up to five times better than steel, and die casting processes preserve this property through uniform material structure. This thermal efficiency is critical for components like engine cylinder heads, LED heat sinks, and power electronics enclosures, where effective heat dissipation directly impacts performance and longevity. We optimize die cast part designs to maximize heat transfer, incorporating features like extended surfaces, fins, and internal cooling passages that leverage aluminum’s conductivity. The near-net-shape production of die casting ensures these thermal features maintain their integrity without the disruptions caused by welding or assembly. Compared to plastic components with metal inserts, die cast aluminum provides more consistent thermal performance across the entire part, eliminating hot spots that can degrade performance. By efficiently managing heat, aluminum die casting enables high-performance components to operate at peak levels even under extreme conditions.

Aluminum Die Casting: Cost-Effectiveness for High-Performance Manufacturing

Aluminum die casting delivers significant cost advantages for producing high-performance components compared to alternative manufacturing methods. While initial tooling costs may be higher, the process’s efficiency and material savings create lower total costs for medium to high production volumes. Die casting eliminates the need for multiple manufacturing steps—such as machining, welding, and assembly—required by other processes, reducing labor and equipment expenses. The high material utilization rate (typically 95% or higher) minimizes waste compared to subtractive processes like CNC machining, which can waste 50% or more of raw material. For high-performance components requiring complex geometries, the cost savings are even more pronounced, as die casting integrates features that would require expensive secondary operations with other methods. Additionally, the long lifespan of die casting molds (often exceeding 100,000 cycles) spreads tooling costs across thousands of parts. By reducing both material waste and production steps, aluminum die casting makes high-performance components more accessible without compromising quality or performance.

Aluminum Die Casting: Design Flexibility for Innovating High-Performance Solutions

The design flexibility offered by aluminum die casting empowers engineers to innovate high-performance components that meet evolving industry demands. Unlike many manufacturing processes that impose design constraints, die casting allows for bold, performance-optimized designs with complex shapes, varying wall thicknesses, and integrated features. This flexibility enables us to create components that precisely match performance requirements—whether that means thin walls for weight reduction, reinforced sections for strength, or intricate details for functional integration. We use computer-aided design (CAD) and mold flow simulation to test and refine designs before production, identifying opportunities to enhance performance through features like optimized ribbing or strategic material placement. For high-performance applications requiring customization, die casting supports design iterations with relatively low incremental costs compared to tooling changes for forging or extrusion. This adaptability makes aluminum die casting ideal for developing next-generation high-performance components, allowing industries to continuously improve efficiency, durability, and functionality in their products.