Aluminum Die Casting: Closed-Loop Material Recycling for Circular Economy

Aluminum die casting plays a pivotal role in sustainable manufacturing through its robust closed-loop material recycling systems that support circular economy principles. Unlike many manufacturing processes that generate significant waste, aluminum die casting allows us to recycle nearly 100% of production scrap, including sprues, runners, and defective parts. We collect these materials, melt them down, and reuse them in subsequent casting cycles without compromising quality. This reduces reliance on primary aluminum production, which requires extensive mining and consumes 95% more energy than recycling. For every ton of recycled aluminum used in die casting, we save approximately 8 tons of bauxite ore and 14,000 kWh of energy. Our recycling programs also extend to end-of-life products—old die cast components from automobiles or electronics are collected, processed, and reintroduced into the production cycle. This material circularity not only minimizes waste sent to landfills but also creates a more resilient supply chain less dependent on volatile raw material markets, making aluminum die casting a cornerstone of sustainable manufacturing practices.

Aluminum Die Casting: Energy Efficiency in Production Processes

Aluminum die casting contributes to sustainable manufacturing through continuous improvements in energy efficiency across its production processes. Modern die casting facilities incorporate advanced technologies that reduce energy consumption at every stage, from melting to casting. We use high-efficiency induction furnaces that heat aluminum with 70% energy efficiency, compared to 40% efficiency in traditional fuel-fired furnaces. Variable-speed pumps and servo-driven hydraulic systems in die casting machines adjust energy usage based on production demands, reducing idle energy waste by up to 30%. Smart heating and cooling systems optimize temperature control, minimizing energy loss during mold heating and molten metal processing. We’ve also implemented energy recovery systems that capture and reuse waste heat from furnaces and cooling processes to warm facility spaces or preheat materials. These efficiency measures have reduced the energy required to produce each die cast part by 25% over the past decade, significantly lowering the carbon footprint of aluminum die casting operations and aligning with global sustainability goals.

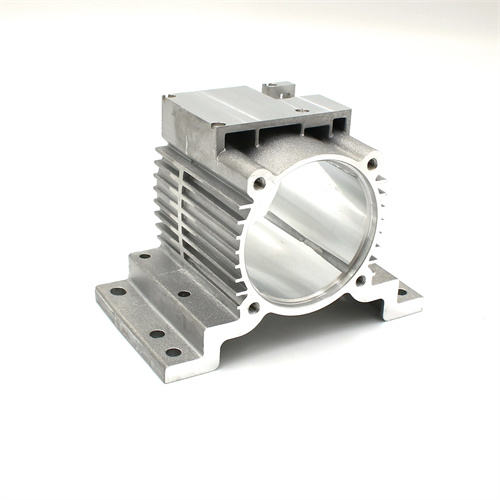

Aluminum Die Casting: Waste Reduction Through Near-Net-Shape Production

Aluminum die casting advances sustainable manufacturing by minimizing material waste through near-net-shape production capabilities. Unlike subtractive manufacturing processes such as machining, which often remove 30-70% of raw material as scrap, die casting uses only the precise amount of aluminum needed to fill the mold cavity. This achieves material utilization rates of 95% or higher, drastically reducing waste generation. The ability to cast complex geometries with integrated features eliminates the need for multiple components that would require additional materials and assembly. For example, a die cast automotive component that replaces five separate machined parts reduces material usage by 40% while eliminating assembly scrap. Even the minimal waste generated from gating systems and sprues is fully recyclable, as we collect and reprocess these materials in-house. By designing parts specifically for die casting, we optimize material distribution to eliminate excess thickness, further reducing material consumption. This waste reduction not only lowers raw material costs but also decreases the environmental impact associated with material extraction, processing, and waste disposal.

Aluminum Die Casting: Lightweighting for Energy-Efficient End Products

Aluminum die casting drives sustainability in manufacturing by enabling the production of lightweight components that reduce energy consumption in end-use products. Aluminum’s natural lightness—combined with die casting’s ability to create strong, thin-walled parts—results in components that are 30-50% lighter than equivalent steel parts. In automotive applications, this lightweighting translates to significant fuel savings: every 10% reduction in vehicle weight improves fuel efficiency by 6-8%. For electric vehicles, lighter die cast components extend battery range by reducing energy demands. In aerospace, lightweight die cast parts decrease aircraft fuel consumption, with estimates showing that a 1% weight reduction saves approximately 0.7% in fuel usage. Even in industrial machinery, lighter components reduce energy requirements for operation and transportation. By enabling widespread lightweighting across industries, aluminum die casting contributes to long-term energy savings throughout the product lifecycle, from manufacturing to end use and eventual recycling. This multiplier effect makes die casting a powerful tool for reducing global energy consumption and greenhouse gas emissions.

Aluminum Die Casting: Low-Impact Production Through Clean Technologies

Aluminum die casting facilities are adopting clean technologies that minimize environmental impact, solidifying their role in sustainable manufacturing. We’ve replaced hazardous chemicals traditionally used in mold release agents with biodegradable, water-based alternatives that reduce volatile organic compound (VOC) emissions by 90%. Advanced air filtration systems capture and remove particulate matter and fumes from melting and casting processes, improving air quality and protecting worker health. Water recycling systems treat and reuse 95% of the water used in cooling and cleaning processes, reducing freshwater consumption and preventing wastewater pollution. Digital monitoring systems track emissions in real time, ensuring compliance with environmental regulations and enabling continuous improvement. We’re also transitioning to renewable energy sources, with many die casting facilities now powered by solar, wind, or hydroelectric energy that reduces reliance on fossil fuels. These clean technology implementations have transformed aluminum die casting from an energy-intensive process to a model of environmentally responsible manufacturing, demonstrating how industrial production can align with sustainability objectives.

Aluminum Die Casting: Supply Chain Sustainability Through Localized Production

Aluminum die casting enhances sustainable manufacturing by supporting localized production networks that reduce supply chain environmental impact. The versatility of die casting allows manufacturers to produce complex components locally, eliminating the need for long-distance transportation of multiple subparts from global suppliers. This localization reduces carbon emissions associated with shipping—transportation accounts for approximately 25% of global greenhouse gas emissions. By consolidating multiple components into single die cast parts, we simplify supply chains, reducing the number of suppliers and transportation routes required. Our regional die casting hubs serve local manufacturing clusters, minimizing delivery distances and enabling just-in-time production that reduces inventory storage needs and associated energy use. We also collaborate with local recyclers to create regional material loops, where end-of-life products are collected and recycled into new die cast components nearby. This localized approach not only reduces environmental impact but also increases supply chain resilience, making manufacturing less vulnerable to disruptions in global transportation networks while supporting local economies.