Aluminum Die Casting: Lightweight Solutions for Fuel Efficiency

Aluminum die casting stands out as the ideal choice for automotive parts due to its ability to produce lightweight components that significantly improve fuel efficiency. Aluminum’s natural density is approximately one-third that of steel, and die casting processes allow us to create strong, thin-walled parts that maintain structural integrity while reducing vehicle weight. For every 10% reduction in vehicle weight achieved through aluminum die cast components, fuel efficiency improves by 6-8%—a critical factor as automakers strive to meet strict emissions regulations. In electric vehicles, lightweight die cast parts extend battery range by reducing energy consumption, addressing a key consumer concern. From engine brackets to transmission housings, aluminum die casting enables weight reduction without compromising safety or performance. Components like aluminum die cast wheels, which are 40% lighter than steel alternatives, reduce unsprung weight, improving handling and braking efficiency. By prioritizing lightweighting through aluminum die casting, automakers can achieve sustainability goals while enhancing overall vehicle performance.

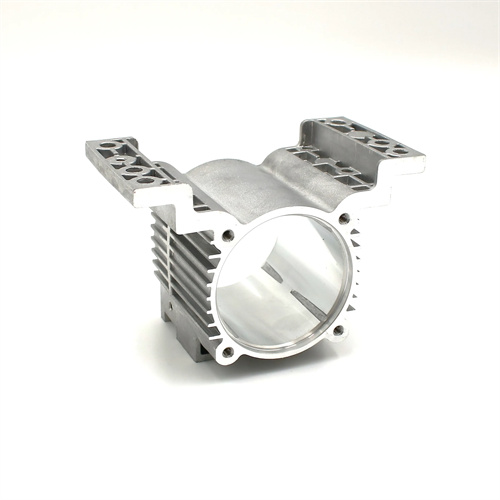

Aluminum Die Casting: Complex Geometry Integration for Reduced Assembly

The ability of aluminum die casting to integrate complex geometries into single automotive parts makes it superior to traditional manufacturing methods, reducing assembly requirements and improving reliability. Unlike processes that require welding or fastening multiple components, die casting can produce intricate parts with integrated features such as internal channels, mounting points, and reinforcing ribs in one production step. For example, a die cast engine cylinder head can incorporate coolant passages, valve seats, and sensor mounts that would otherwise require separate fabrication and assembly. This integration reduces the number of parts in an automotive assembly by 30-50%, cutting assembly time and labor costs significantly. Fewer components also mean fewer potential failure points, enhancing the durability of critical systems like braking and steering. The tight tolerances achieved through die casting (typically ±0.02mm) ensure precise fitment between parts, reducing noise, vibration, and harshness (NVH) in vehicles—key factors in passenger comfort and perceived quality.

Aluminum Die Casting: High-Volume Production Efficiency for Automotive Demand

Aluminum die casting excels in meeting the high-volume production demands of the automotive industry, delivering consistent quality at scale. Automotive manufacturers require millions of identical parts annually, and die casting’s rapid cycle times—often 30-90 seconds per part—enable mass production that keeps pace with assembly line needs. Once molds are optimized, die casting machines can operate continuously, producing thousands of parts daily with minimal variation. This repeatability ensures that every component meets strict automotive specifications, from dimensional accuracy to material strength. Automated die casting cells further enhance efficiency by integrating robotics for part extraction, trimming, and quality inspection, reducing labor costs and human error. For high-volume components like water pumps, alternator housings, and suspension parts, aluminum die casting’s production efficiency translates to lower per-unit costs compared to machining or forging. This combination of speed, consistency, and scalability makes die casting indispensable for meeting automotive production schedules and cost targets.

Aluminum Die Casting: Material Performance for Automotive Durability

Aluminum die casting provides exceptional material performance that meets the rigorous durability requirements of automotive parts operating in harsh conditions. Modern aluminum die casting alloys, such as A380 and ADC12, offer excellent strength-to-weight ratios, corrosion resistance, and thermal conductivity—critical properties for automotive applications. Heat-treated die cast parts can achieve tensile strengths exceeding 300 MPa, making them suitable for structural components like subframe brackets and engine mounts. The uniform material structure created through die casting ensures consistent performance across the entire part, eliminating weak points found in welded assemblies. Aluminum’s natural thermal conductivity also makes die cast parts ideal for heat-managing components such as radiator end tanks and oil pans, efficiently dissipating heat to prevent engine overheating. Additionally, aluminum die cast parts resist corrosion better than many steel components, especially when treated with protective coatings, extending service life and reducing maintenance requirements for vehicles in diverse climates.

Aluminum Die Casting: Cost-Effectiveness for Automotive Manufacturing Budgets

Aluminum die casting delivers significant cost advantages for automotive manufacturers through reduced material waste, lower assembly costs, and efficient production processes. While initial tooling investment for die casting molds is higher than for some processes, the per-unit costs decrease dramatically with volume, making it economical for high-production automotive parts. Die casting’s near-net-shape production minimizes material waste—typically less than 5% compared to 30-70% waste in machining processes—reducing raw material expenses. The integration of multiple features into single die cast parts eliminates the need for secondary operations like drilling, welding, and fastening, cutting labor costs by 20-40%. Longer mold life (often exceeding 100,000 cycles) spreads tooling costs across more parts, further lowering unit costs. For example, replacing a multi-part steel assembly with a single aluminum die cast component can reduce total manufacturing costs by 15-25% over the production lifecycle. These cost savings allow automakers to invest in other vehicle improvements while maintaining competitive pricing for consumers.

Aluminum Die Casting: Sustainability Benefits for Eco-Friendly Vehicles

Aluminum die casting supports the automotive industry’s shift toward sustainability by reducing environmental impact throughout the product lifecycle. Aluminum is 100% recyclable, and die casting facilities operate closed-loop recycling systems that reuse nearly all production scrap, reducing reliance on virgin materials. Recycling aluminum requires 95% less energy than producing primary aluminum, significantly lowering the carbon footprint of die cast automotive parts. The lightweight nature of aluminum die cast components also reduces vehicle energy consumption, whether in gasoline-powered cars (lowering fuel use) or electric vehicles (extending battery range). Die casting’s efficient material usage and minimal waste further contribute to sustainability by reducing landfill contributions. Automakers using aluminum die casting can achieve corporate sustainability goals while meeting regulatory requirements for reduced emissions. As the industry transitions to electric mobility, aluminum die casting’s role in producing lightweight, recyclable components will become even more critical for creating truly eco-friendly vehicles.