Fundamental Mechanical Properties of Die Casting Alloys

To effectively select die casting alloys for specific applications, we must first understand their fundamental mechanical properties, which determine performance under various stresses. Tensile strength, yield strength, ductility, and hardness form the core characteristics we evaluate. Aluminum die casting alloys typically exhibit tensile strengths ranging from 200–350 MPa, with yield strengths between 120–280 MPa, making them versatile for structural components. Zinc alloys offer higher hardness (80–110 HB) than aluminum but slightly lower tensile strength (200–300 MPa), providing excellent wear resistance for moving parts.

Magnesium die casting alloys, while lighter, deliver impressive specific strength—their tensile strength-to-weight ratio often exceeds that of aluminum, ranging from 200–270 MPa with lower density. Ductility, measured by elongation percentage, varies significantly: zinc alloys show 10–15% elongation, aluminum alloys 2–10%, and magnesium alloys 2–8%, affecting their suitability for applications requiring flexibility. By comparing these mechanical properties, we can match die casting alloys to the stress and load requirements of different manufacturing projects.

Thermal Properties of Common Die Casting Alloys

Thermal properties play a critical role in determining die casting alloys’ suitability for high-temperature applications, and we analyze these characteristics thoroughly during material selection. Thermal conductivity, which affects heat dissipation, varies notably among common alloys: aluminum die casting alloys excel here with 100–150 W/m·K, making them ideal for heat sinks and cooling components. Zinc alloys offer moderate thermal conductivity (100 W/m·K), suitable for moderate heat applications like appliance parts.

Magnesium die casting alloys provide 70–130 W/m·K, balancing lightweight properties with acceptable heat transfer. Coefficient of thermal expansion (CTE) is another key factor—aluminum alloys have a CTE of 20–24 μm/m·K, zinc alloys 26–32 μm/m·K, and magnesium alloys 25–28 μm/m·K. These values determine dimensional stability under temperature fluctuations, critical for precision components. We also evaluate thermal stability: aluminum alloys maintain strength at 120–150°C, while specialized heat-resistant formulations extend this range. Understanding these thermal properties ensures we select die casting alloys capable of performing in their operating temperature environments.

Corrosion Resistance in Die Casting Alloys

Corrosion resistance is a vital property determining the service life of die casting alloys, especially in harsh or exposed environments. We assess both natural resistance and the effects of surface treatments on this property. Aluminum die casting alloys form a natural oxide layer that provides moderate corrosion resistance, but this can be enhanced significantly through treatments like anodizing or chromate conversion coatings, making them suitable for outdoor applications. Without protection, however, they may corrode in saltwater environments.

Zinc die casting alloys inherently resist corrosion better than untreated steel, forming a protective patina that slows further oxidation, making them ideal for decorative components without additional coatings. Magnesium die casting alloys are more susceptible to corrosion, particularly in humid or salty conditions, requiring protective treatments like conversion coatings or plating to ensure durability. We conduct salt spray testing and environmental exposure trials to quantify corrosion resistance, comparing results across alloy types. This analysis ensures we recommend die casting alloys with appropriate corrosion resistance for their intended operating environments, from dry indoor settings to harsh industrial or marine conditions.

Castability and Formability of Die Casting Alloys

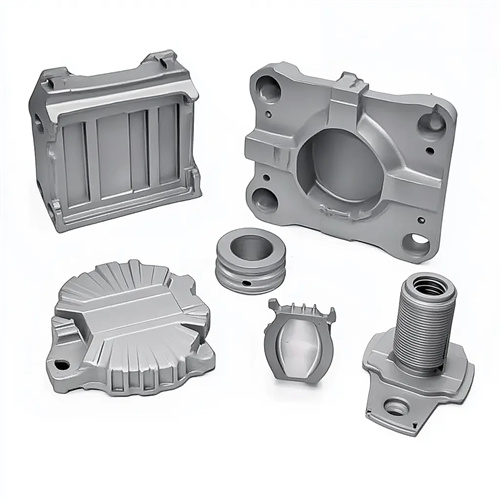

Castability—the ease with which die casting alloys fill complex mold cavities—and formability significantly impact manufacturing efficiency and part quality, making these properties crucial in our evaluation. Aluminum die casting alloys offer excellent castability with good fluidity, enabling production of intricate shapes with thin walls (0.8–1.5 mm) while maintaining structural integrity. Their ability to withstand high injection pressures allows for detailed features and tight tolerances.

Zinc die casting alloys excel in castability, flowing easily into the finest details with minimal pressure, making them perfect for small components with thin walls (0.5–1 mm) and complex geometries. This property reduces the need for secondary machining. Magnesium die casting alloys also demonstrate good fluidity but require precise temperature control (650–700°C) and protective atmospheres during casting. We evaluate factors like melt viscosity, solidification rate, and shrinkage characteristics, as these affect dimensional accuracy and defect formation. By understanding castability differences, we can select die casting alloys that match production requirements, reducing scrap rates and ensuring consistent quality.

Electrical and Thermal Conductivity in Die Casting Alloys

Electrical and thermal conductivity properties make certain die casting alloys indispensable for specific industrial applications, and we carefully assess these characteristics during material selection. Aluminum die casting alloys provide excellent electrical conductivity (30–40% IACS) and thermal conductivity, making them ideal for heat sinks, electrical enclosures, and components requiring efficient heat dissipation. Their conductivity can be further optimized by adjusting alloy composition to reduce impurity levels.

Zinc die casting alloys offer moderate electrical conductivity (25–30% IACS), suitable for electrical connectors and shielding applications where conductivity combines with formability. Magnesium die casting alloys provide lower electrical conductivity (20–25% IACS) but offer unique benefits in weight-sensitive electrical components. Thermal conductivity follows similar patterns, with aluminum outperforming both zinc and magnesium for heat transfer applications. We measure these properties using specialized equipment, comparing results against application requirements for current carrying capacity, electromagnetic shielding, and heat management. This ensures we select die casting alloys that meet both mechanical and functional performance criteria.

Comparative Property Analysis of Major Die Casting Alloys

A comparative analysis of key properties across major die casting alloys allows us to make informed material selections based on application priorities. Aluminum alloys strike an excellent balance between strength, corrosion resistance, and cost, making them the most widely used option for general manufacturing. Their versatility across mechanical, thermal, and electrical properties suits diverse applications from automotive parts to consumer electronics.

Zinc alloys excel in precision, surface finish, and cost-effectiveness for small components, offering superior hardness and impact resistance that benefits hardware and decorative parts. Magnesium alloys provide unmatched lightweight properties with good specific strength, ideal for weight-critical applications like aerospace components and electric vehicle parts despite higher material costs. By creating property comparison matrices, we can visualize trade-offs: aluminum offers better corrosion resistance than magnesium, zinc provides superior castability than aluminum for intricate parts, and magnesium delivers weight savings no other die casting alloy can match. This comprehensive analysis ensures we recommend the optimal die casting alloy based on each application’s unique performance requirements and constraints.