Strength-to-Weight Balance in Automotive Die Casting Alloys

Die casting alloys provide the essential strength-to-weight balance critical for modern automotive high-strength components. We rely on this unique property combination to meet increasingly strict fuel efficiency standards without compromising safety. Aluminum die casting alloys, for example, deliver tensile strengths up to 350 MPa while maintaining 30% lower weight than equivalent steel components. This reduction directly improves vehicle dynamics and reduces energy consumption, whether for internal combustion engines or electric vehicles.

Magnesium die casting alloys push this advantage further, offering 15–20% weight savings compared to aluminum while maintaining sufficient strength for structural parts like subframes and suspension components. We carefully engineer these alloys to ensure they withstand the constant stresses of vehicle operation—from road vibrations to payload pressures. The ability to achieve high strength without excessive weight makes die casting alloys indispensable in automotive design, allowing engineers to create lighter vehicles that still meet the rigorous strength requirements for passenger safety and durability.

Manufacturing Efficiency of Die Casting Alloys for Complex Parts

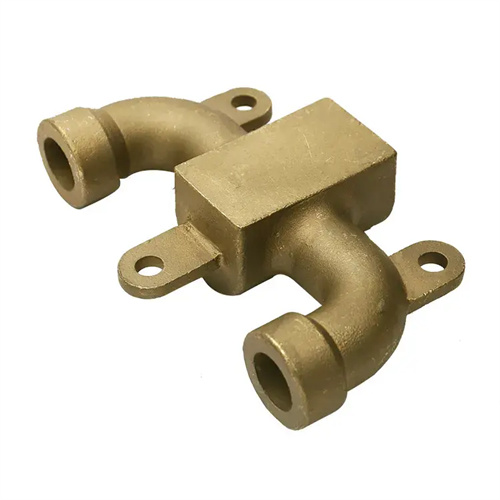

The manufacturing efficiency of die casting alloys enables production of complex high-strength automotive parts that would be difficult or impossible to create with other processes. We leverage the excellent fluidity of aluminum and zinc die casting alloys to produce intricate components with integrated features—eliminating the need for multiple parts and fasteners. This not only reduces weight but also creates stronger, more rigid structures through monolithic design.

Die casting allows us to incorporate reinforcing ribs, bosses, and complex geometries in high-strength automotive parts like transmission cases and engine cradles, optimizing strength where needed while minimizing material in non-critical areas. The process achieves tight tolerances consistently, reducing the need for secondary machining and ensuring component compatibility during assembly. For high-volume production, die casting alloys enable faster cycle times than forging or machining, lowering per-unit costs while maintaining strength integrity. This manufacturing efficiency makes die casting alloys the practical choice for producing complex, high-strength automotive components at scale.

Tailored Mechanical Properties of Automotive Die Casting Alloys

We engineer die casting alloys with tailored mechanical properties to meet the specific demands of different high-strength automotive applications. Through careful alloy composition and heat treatment, we can customize properties like tensile strength, fatigue resistance, and impact toughness for particular components. For suspension parts requiring high fatigue strength, we develop aluminum die casting alloys with fine-grained microstructures that resist crack propagation under repeated stress.

Transmission components benefit from die casting alloys with enhanced wear resistance, achieved through controlled silicon content in aluminum formulations. For safety-critical parts like steering knuckles, we specify heat-treated die casting alloys that maintain strength at elevated temperatures, ensuring performance during extreme operating conditions. This ability to tailor mechanical properties allows die casting alloys to meet the diverse strength requirements across different automotive systems, from powertrain to chassis, making them versatile solutions for high-strength applications.

Structural Integrity Under Extreme Conditions

Die casting alloys provide the structural integrity required for high-strength automotive parts operating under extreme conditions. We subject these alloys to rigorous testing that simulates the most demanding automotive environments—from sub-zero temperatures to 150°C engine bay conditions. Aluminum die casting alloys maintain their strength across this temperature range, making them suitable for engine components exposed to heat and vibration.

In crash scenarios, the energy absorption characteristics of die casting alloys become critical. We optimize zinc and aluminum die casting alloys to deform predictably during impacts, absorbing energy to protect vehicle occupants while maintaining structural integrity in critical areas. For off-road vehicles, die casting alloys resist the constant shock and vibration that would fatigue lesser materials. Salt spray and corrosion testing ensures these alloys maintain strength in harsh winter conditions or coastal environments. The ability to retain structural integrity under extreme conditions confirms die casting alloys as essential materials for high-strength automotive parts.

Cost-Effective Strength Solutions with Die Casting Alloys

Die casting alloys provide cost-effective high-strength solutions that balance performance with affordability in automotive manufacturing. While initial tooling investment for die casting may be higher than for some processes, the long-term savings are substantial. The near-net-shape capability of die casting reduces material waste by up to 50% compared to machining from solid billets, lowering material costs for high-strength components.

The ability to produce complex high-strength parts in a single operation reduces assembly costs and eliminates potential failure points from fasteners. We find that aluminum die casting alloys offer particular cost advantages, providing 80% of the strength of steel at approximately 50% of the manufacturing cost for complex components. Even premium magnesium die casting alloys deliver cost benefits through fuel savings over the vehicle lifecycle. By combining high strength with production efficiency, die casting alloys enable automakers to meet performance requirements without prohibitive cost increases, making high-strength designs accessible across vehicle segments.

Future-Proofing Automotive Design with Advanced Die Casting Alloys

Advanced die casting alloys are future-proofing automotive design by enabling the next generation of high-strength, lightweight vehicles. As automakers transition to electric vehicles, we’re developing die casting alloys that meet new performance demands—higher strength for battery enclosure protection, better thermal conductivity for heat management, and lighter weight to extend range. Our latest aluminum-scandium die casting alloys achieve 10% higher strength than conventional formulations while maintaining recyclability.

We’re also pioneering large-format die casting techniques using high-strength alloys to produce entire car bodies from fewer components, reducing weight while increasing structural rigidity. These innovations allow automakers to design vehicles with improved crash performance and energy efficiency. As emission standards tighten globally, die casting alloys will play an increasingly critical role in reducing vehicle weight without sacrificing strength. By continuing to advance die casting alloy technology, we ensure automakers have the materials needed to meet future regulatory requirements and consumer expectations for safe, efficient vehicles.