Lightweight Advantage of Magnesium Die Casting in Transportation

Magnesium die casting delivers unparalleled lightweight advantages that transform performance in automotive and aerospace applications. With a density of just 1.7–1.8 g/cm³, magnesium components are 33% lighter than aluminum and 75% lighter than steel equivalents. In automotive design, this translates directly to improved fuel efficiency—every 10% weight reduction increases fuel economy by approximately 6–8%. For electric vehicles, magnesium die casting parts reduce battery load, extending driving range by 5–10% without compromising structural integrity.

In aerospace applications, where weight directly impacts payload capacity and fuel consumption, magnesium die casting components offer critical weight savings for airframe structures and interior components. We’ve achieved weight reductions of 20–30% compared to aluminum in aircraft seat frames and cabin fixtures, contributing to lower operational costs. This lightweight advantage doesn’t require sacrificing size or functionality, as magnesium die casting maintains the dimensional capabilities needed for complex transportation components. The material’s natural lightness makes magnesium die casting indispensable for modern mobility solutions focused on efficiency.

High Strength-to-Weight Ratio in Magnesium Die Casting Components

Magnesium die casting components provide exceptional strength-to-weight ratios that meet the demanding performance requirements of automotive and aerospace industries. When properly alloyed with elements like aluminum, zinc, and rare earth metals, magnesium die castings achieve tensile strengths of 200–300 MPa while maintaining their lightweight properties. This combination allows engineers to design structural components that withstand operational stresses—from engine vibrations to flight turbulence—without unnecessary weight.

In automotive applications, we use magnesium die casting for load-bearing parts like steering column brackets and transmission housings, where strength is critical but weight must be minimized. Aerospace-grade magnesium alloys deliver even higher performance, with specialized formulations offering creep resistance at elevated temperatures for engine compartment components. The specific strength of magnesium die casting exceeds many aluminum alloys, making it ideal for parts where both strength and weight are critical design factors. This mechanical advantage enables safer, more efficient vehicles and aircraft through optimized structural design.

Design Flexibility Enabled by Magnesium Die Casting Processes

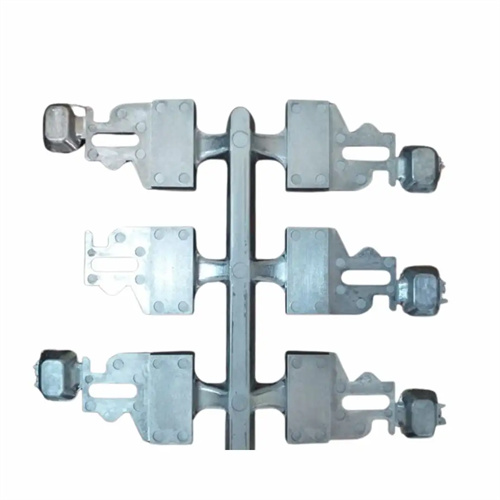

Magnesium die casting offers superior design flexibility that supports innovation in automotive and aerospace component development. The excellent fluidity of molten magnesium allows us to produce complex geometries with thin walls (0.8–2 mm), intricate details, and integrated features that would be difficult to achieve with other metals. This capability enables consolidation of multiple parts into single magnesium die casting components, reducing assembly steps, eliminating fasteners, and creating stronger overall structures.

We leverage this design freedom to incorporate functional features directly into magnesium die castings—such as cooling channels in engine components or mounting points in aerospace brackets—optimizing performance while reducing weight. The process achieves tight tolerances (±0.02 mm for critical dimensions), ensuring component compatibility in precision assemblies like automotive powertrains and aircraft avionics. For low-volume aerospace prototypes or high-volume automotive production, magnesium die casting adapts easily to diverse design requirements, supporting both innovation and manufacturing efficiency across transportation sectors.

Thermal and Energy Efficiency Benefits of Magnesium Die Casting

Magnesium die casting provides thermal and energy efficiency benefits that enhance performance in automotive and aerospace systems. With thermal conductivity of 70–130 W/m·K, magnesium dissipates heat effectively, making it ideal for automotive engine components and aerospace electronics housings where thermal management is critical. We design magnesium die casting heat sinks that efficiently transfer heat away from sensitive components, reducing the need for additional cooling systems and further saving weight.

The energy efficiency benefits extend beyond operation to production: magnesium die casting requires lower melting temperatures (650–700°C) than aluminum, reducing energy consumption during manufacturing by 10–15%. In automotive applications, reduced vehicle weight from magnesium components lowers energy requirements during operation, whether for internal combustion engines or electric motors. For aircraft, the fuel savings from lightweight magnesium die casting components accumulate over thousands of flights, creating significant long-term energy efficiency gains. These thermal and energy advantages make magnesium die casting a sustainable choice for transportation industries.

Corrosion Resistance and Durability in Magnesium Die Casting

Modern magnesium die casting components achieve impressive corrosion resistance and durability through advanced alloys and surface treatments, addressing historical limitations. While pure magnesium is highly reactive, our specialized alloys containing aluminum, zinc, and manganese form protective surface layers that naturally resist corrosion. We enhance this protection with advanced surface treatments like conversion coatings, anodizing, and electroplating, creating magnesium die casting components that withstand harsh automotive and aerospace environments.

In automotive applications, magnesium die castings with proper protection perform reliably in undercarriage components exposed to road salts and moisture. Aerospace magnesium components undergo rigorous testing to ensure durability in high-humidity and temperature-fluctuating environments. We conduct accelerated corrosion testing, including salt spray exposure and cyclic humidity trials, to validate performance. With these advancements, magnesium die casting components now meet the 10–15 year service life requirements for automotive parts and the stringent durability standards for aerospace applications, proving their long-term reliability.

Cost-Effectiveness and Sustainability of Magnesium Die Casting

Magnesium die casting delivers compelling cost-effectiveness and sustainability benefits for automotive and aerospace manufacturers. While magnesium has higher raw material costs than aluminum, its lightweight properties create downstream savings: lighter vehicles require smaller engines or batteries, reducing overall production costs. The design consolidation enabled by magnesium die casting lowers assembly costs by reducing part counts—we’ve achieved 30–50% part reductions in complex assemblies like instrument panels.

From a sustainability perspective, magnesium die casting supports circular manufacturing practices with 95% recyclability and lower energy requirements for recycling compared to primary production. We implement closed-loop recycling systems for magnesium scrap, reducing waste and material costs. In both automotive and aerospace sectors, the fuel savings from lightweight magnesium components over the product lifecycle far exceed any initial material cost premiums. As sustainability regulations tighten, magnesium die casting’s environmental advantages—from reduced emissions to high recyclability—position it as a cost-effective, future-proof solution for transportation manufacturing.