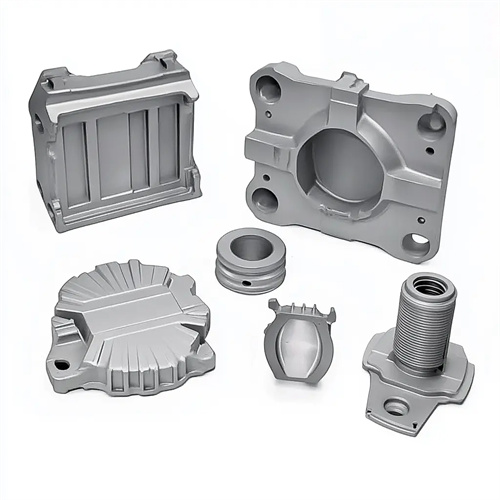

Material Efficiency in Magnesium Die Casting Processes

Magnesium die casting plays a pivotal role in sustainable manufacturing through exceptional material efficiency that minimizes waste. The near-net-shape capability of magnesium die casting allows us to produce complex components with minimal material excess, reducing raw material consumption by 30–50% compared to machining from solid billets. The material’s excellent fluidity enables thin-walled designs (0.5–2 mm) that use only necessary material, further optimizing resource utilization.

We’ve implemented precision dosing systems that deliver exact amounts of molten magnesium to die cavities, eliminating over-pouring and reducing scrap. Advanced simulation tools optimize part designs for material distribution, ensuring strength where needed while removing excess in non-critical areas. This material efficiency not only conserves natural resources but also reduces energy consumption associated with raw material extraction and processing. By maximizing material utilization, magnesium die casting significantly lowers the environmental footprint of manufacturing operations.

Energy Optimization in Magnesium Die Casting Production

Energy optimization in magnesium die casting production enhances its role in eco-friendly manufacturing. While magnesium requires specific processing conditions, we’ve developed energy-efficient practices that reduce overall consumption. The lower melting point of magnesium (650–700°C) compared to aluminum reduces energy needs for melting by approximately 20%. We’ve integrated regenerative braking systems into die casting machines that capture and reuse energy during deceleration, cutting overall energy consumption by 15–20%.

Our facility-wide energy management systems optimize heating, cooling, and lighting based on production schedules, minimizing idle energy use. We’ve also implemented solar-powered auxiliary systems for material handling and climate control in magnesium die casting areas. Advanced insulation around furnace and die casting cells retains heat, reducing energy loss during production. These energy optimization measures make magnesium die casting a more sustainable option, aligning with eco-friendly manufacturing goals by reducing greenhouse gas emissions associated with energy production.

Circular Economy Contributions of Magnesium Die Casting

Magnesium die casting makes significant contributions to circular economy models in sustainable manufacturing. Magnesium is highly recyclable, with recycled material retaining 95% of its original properties while requiring only 5% of the energy needed for primary production. We operate closed-loop recycling systems that collect magnesium die casting scrap directly from production lines, reprocessing it into new feedstock without quality degradation.

This internal recycling reduces waste sent to landfills by over 90% in our magnesium die casting operations. We also collaborate with end-of-life product recyclers to recover magnesium components from discarded products, creating a circular supply chain that minimizes virgin material extraction. The compatibility of recycled magnesium with virgin alloys allows flexible blending to meet specific application requirements. By enabling efficient material circulation, magnesium die casting supports the transition from linear to circular manufacturing models, enhancing overall sustainability.

Carbon Footprint Reduction Through Magnesium Die Casting

Magnesium die casting contributes to significant carbon footprint reduction in manufacturing and end-use applications. The lightweight properties of magnesium components reduce energy consumption throughout product lifecycles—lighter vehicles require less fuel, reducing operational emissions by 5–10% over their service life. In aerospace applications, magnesium die casting weight savings translate to lower jet fuel consumption and associated carbon emissions.

Manufacturing-phase emissions are minimized through energy-efficient processes and high recyclability. Our lifecycle assessments show that magnesium die casting components have 30–40% lower carbon footprints than equivalent steel parts when considering both production and operational phases. We’ve also reduced embodied carbon by sourcing magnesium from producers using renewable energy for extraction and processing. These carbon reduction benefits make magnesium die casting a strategic choice for manufacturers seeking to meet sustainability targets and reduce environmental impact across product lifecycles.

Eco-Friendly Process Innovations in Magnesium Die Casting

Eco-friendly process innovations have strengthen magnesium die casting’s role in sustainable manufacturing. We’ve replaced hazardous sulfur hexafluoride (SF₆)—a potent greenhouse gas—with environmentally benign protective gas mixtures containing carbon dioxide and nitrogen, reducing greenhouse gas emissions by over 90% during casting. Water-based lubricants and release agents have eliminated volatile organic compound (VOC) emissions from our magnesium die casting processes.

Our closed-loop cooling systems recirculate and treat water used in die temperature control, reducing freshwater consumption by 70% and preventing contamination of natural water sources. We’ve also developed low-emission cleaning processes for magnesium die casting components that use biodegradable detergents instead of harsh chemicals. These process innovations demonstrate that magnesium die casting can be conducted with minimal environmental impact, aligning with the strictest eco-friendly manufacturing standards while maintaining production efficiency and part quality.

Sustainable Applications Driving Magnesium Die Casting Adoption

Sustainable applications across industries are driving increased adoption of magnesium die casting in eco-friendly manufacturing. In electric vehicles, magnesium die casting components reduce battery load, extending range and reducing the need for larger, resource-intensive battery packs. Renewable energy systems use magnesium die casting for lightweight, corrosion-resistant components in wind turbines and solar trackers, improving energy capture efficiency while minimizing material use.

Consumer electronics manufacturers use magnesium die casting to create durable, lightweight devices that extend battery life and reduce e-waste through longer product lifespans. Medical equipment benefits from magnesium’s biocompatibility and recyclability, supporting sustainable healthcare practices. These applications leverage magnesium die casting’s unique combination of lightweight properties, material efficiency, and recyclability to achieve specific sustainability goals. As industries prioritize eco-friendly manufacturing, magnesium die casting is increasingly recognized as a key enabler of more sustainable products and production processes.