Lightweight Design Benefits in Magnesium Die Casting for Portable Devices

Magnesium die casting offers unparalleled lightweight design benefits that make it ideal for consumer electronics and medical devices. With a density of just 1.7–1.8 g/cm³, magnesium components are 30% lighter than aluminum and significantly lighter than steel, enhancing portability in handheld devices. For smartphones and tablets, magnesium die casting frames reduce overall weight by 15–20% compared to aluminum, making devices more comfortable to hold for extended periods.

In medical applications, lightweight magnesium die casting components in portable equipment like ultrasound machines and patient monitors improve mobility for healthcare providers. The strength-to-weight ratio of magnesium die casting ensures durability isn’t compromised for lightness—these components withstand daily use and accidental drops common in both consumer and clinical environments. This combination of light weight and robust strength makes magnesium die casting the preferred choice for designing ergonomic, portable devices where user comfort and durability are paramount.

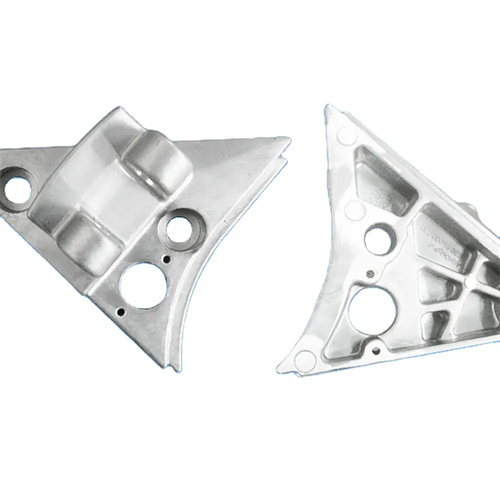

Superior Protection and Structural Integrity in Magnesium Die Casting

Magnesium die casting provides superior protection and structural integrity critical for sensitive consumer electronics and medical devices. The material’s natural rigidity creates robust enclosures that shield internal components from impacts, vibrations, and environmental hazards. In smartphones and laptops, magnesium die casting frames absorb shocks during drops, protecting delicate circuit boards and displays better than plastic or thinner aluminum alternatives.

For medical devices, magnesium die casting enclosures offer enhanced protection for sensitive electronics used in diagnostic equipment, ensuring reliable performance in busy clinical settings. The ability to integrate reinforcing ribs and structural features directly into magnesium die casting designs creates targeted strength where needed, without unnecessary weight. We’ve tested magnesium die casting components to withstand the rigorous drop and vibration standards required for both consumer electronics (IEC 60068) and medical devices (IEC 60601), confirming their superior protective capabilities.

Electromagnetic Shielding Properties of Magnesium Die Casting

The electromagnetic shielding properties of magnesium die casting make it invaluable for consumer electronics and medical devices. Unlike plastic enclosures that require additional shielding layers, magnesium’s inherent conductivity creates a natural Faraday cage, blocking electromagnetic interference (EMI) that can disrupt device performance. In smartphones and wearables, magnesium die casting frames prevent signal interference between components, ensuring reliable connectivity and accurate sensor readings.

In medical environments, where multiple electronic devices operate in close proximity, magnesium die casting enclosures prevent EMI from compromising sensitive equipment like EKG machines and MRI monitors. This natural shielding eliminates the need for heavy, expensive EMI coatings or inserts, reducing both weight and production complexity. We’ve verified that magnesium die casting provides shielding effectiveness exceeding 60 dB across critical frequency ranges, meeting the strict EMI standards for both consumer electronics and medical devices.

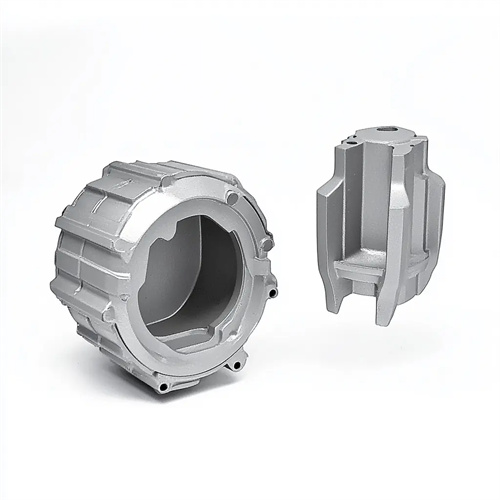

Precision and Complexity in Magnesium Die Casting for Miniaturized Components

Magnesium die casting enables the precision and complexity required for miniaturized components in modern consumer electronics and medical devices. The material’s excellent fluidity allows us to produce intricate geometries with thin walls (0.5–1.5 mm), fine details, and tight tolerances (±0.02 mm) essential for compact device designs. In smartphones, magnesium die casting produces complex frame structures with integrated antenna compartments and port openings in a single piece, reducing assembly steps and improving dimensional accuracy.

For medical devices like insulin pumps and portable diagnostic tools, magnesium die casting creates miniaturized components with precise internal channels and mounting features that would be difficult to achieve with other manufacturing methods. This precision manufacturing capability supports the ongoing trend toward smaller, more powerful devices in both industries. The ability to create complex, miniaturized components efficiently makes magnesium die casting a key enabler of innovation in compact device design.

Biocompatibility and Hygiene in Medical Magnesium Die Casting

Magnesium die casting offers biocompatibility and hygiene benefits that make it suitable for medical device applications. While pure magnesium can react with bodily fluids, specialized magnesium die casting alloys with controlled compositions meet ISO 10993 biocompatibility standards, making them safe for devices used in patient contact. These alloys resist corrosion in clinical environments, maintaining integrity through repeated cleaning cycles.

The non-porous surface of magnesium die casting components prevents bacterial growth, supporting infection control protocols in healthcare settings. Unlike porous materials that require additional coatings, magnesium die casting can be easily cleaned and sterilized using standard medical disinfection methods, including autoclaving for select alloys. This combination of biocompatibility and easy hygiene maintenance makes magnesium die casting ideal for medical devices ranging from surgical instruments to patient monitoring equipment, where safety and cleanliness are critical.

Sustainable and Cost-Effective Production with Magnesium Die Casting

Magnesium die casting offers sustainable and cost-effective production benefits for consumer electronics and medical device manufacturers. The material’s high recyclability (95% recovery rate) aligns with environmental goals in both industries, reducing reliance on virgin materials and minimizing waste. Closed-loop recycling systems in our magnesium die casting operations repurpose scrap into new components, lowering the carbon footprint of production.

While magnesium has higher raw material costs than plastic, its design consolidation capabilities reduce overall production costs by eliminating assembly steps and secondary operations. The long tool life in magnesium die casting (often exceeding 100,000 cycles) creates economies of scale for high-volume consumer electronics. For medical devices, the precision of magnesium die casting reduces costly rework and ensures consistent component quality, supporting regulatory compliance. This balance of sustainability and cost-effectiveness makes magnesium die casting a smart long-term investment for both industries.